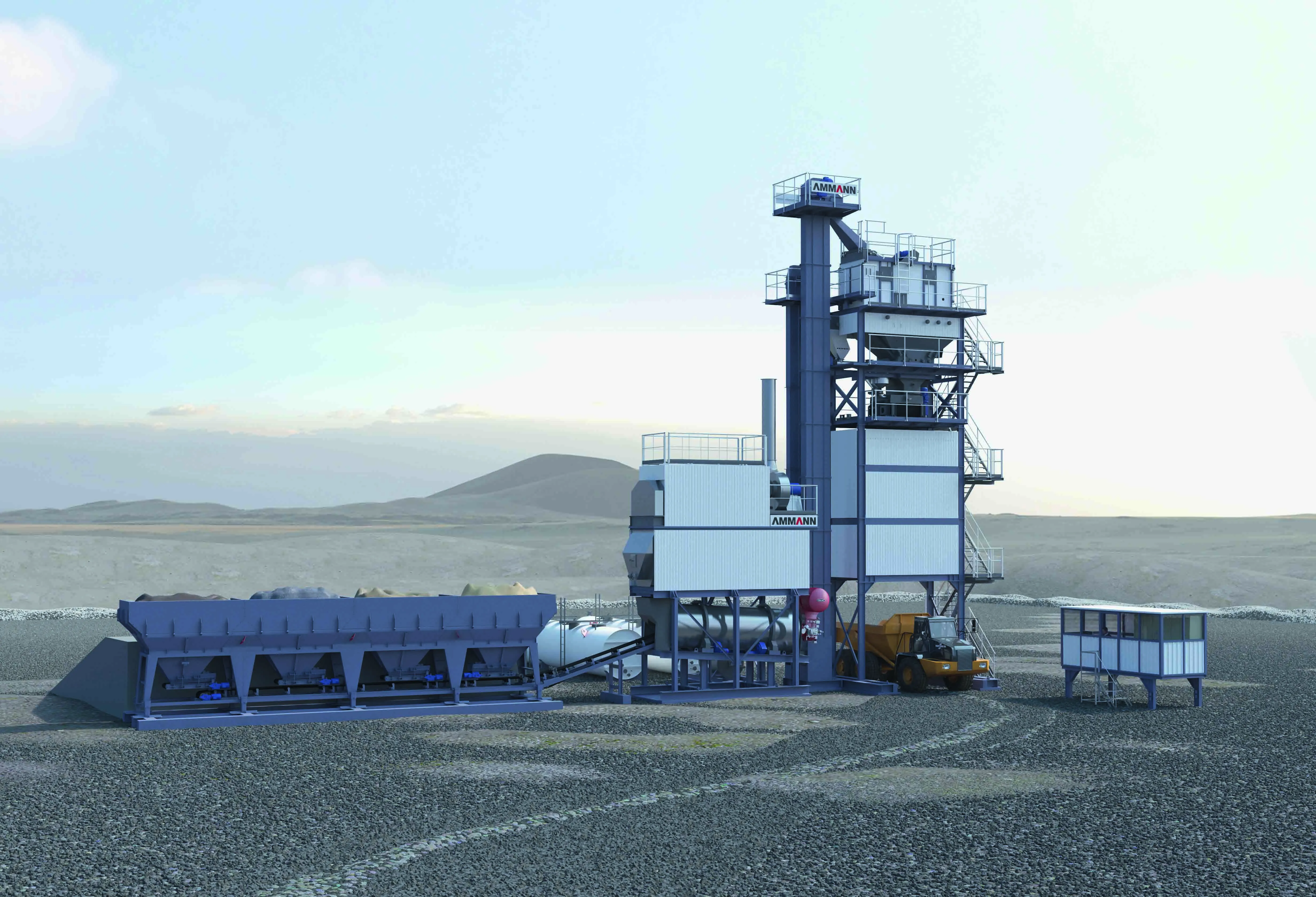

Ammann claims that its new EcoBatch asphalt plant offers versatility and mobility in a single compact package. This modular plant can deliver 60-80tonnes/hour of high quality material for use in demanding road construction applications. The plant is said to be optimised to reduce wear and maintenance needs, with easy access for servicing. Jean-Luc Didier is sales director for Central-South Europe and said, “It has the same control system and accuracy in dosing as we have in the big plants. There’s no need f

January 6, 2017

Read time: 2 mins

Compact dimensions and high quality core components are said to maximise performance and help to make the unit a top performer in the small asphalt mixing plant market, according to Ammann. This newly developed plant concept features tried-and-tested Ammann technology and can be transported in standard containers. The basic layout can be amended with additional features including cold or hot reclaimed asphalt feed, liquid or solid additives and Ammann Foam.

The plant has all the systems of a regular batch type asphalt mixing plant, while being small and compact and equipped with the latest design principles from Ammann. It also offers a host of options ranging from a basic plant to more sophisticated advanced versions. A smaller footprint makes it suitable for small level sites, whilst its ductless design eases assembly.

Maximum mixer capacity is 1.2tonnes, while the hot aggregate silo offers 16tonnes capacity and an optional hot mix storage silo offers a 50tonne capacity. Due to the compact and modular design the plant offers easy transportation, rapid assembly and commissioning due to options such as steel foundations and plug socket cabling, as well as a small footprint for use on sites with space constraints.