A one size fits all approach can be refreshing. And that’s what Finnish crushing and screening bucket company

The company has developed a solution that allows all the different drums for different bucket applications and fragments to fit one frame. For the customer this means versatility and higher utilisation of the unit, saving money and the opportunity to earn more money.

Also showcased this week are ALLU’s new drums with changeable blades, said to be a great tool for waste material handling, pipeline backfilling and padding. The Universal blades match most applications and materials while the Long blades serve on compost and other soft materials increasing capacity.

ALLU’s new stabilisation drums mean no more welding at jobsite as the new X-blades are said to be fast field replaceable in a very short time.

With ALLU’s new TS drum assembly two different fragment sizes are possible with one bucket unit, just by repositioning the screening combs. Based on the application the customer may choose the standard blades for screening (gravel, top soil, compost) or the axe blades for crushing or shredding effect, when undertaking applications involving field bark, plastic bags shredding, waste materials.

All ALLU drums have changeable blades and the company has now added 40 % more wearing surface to the blades in addition to a new patent pending design.

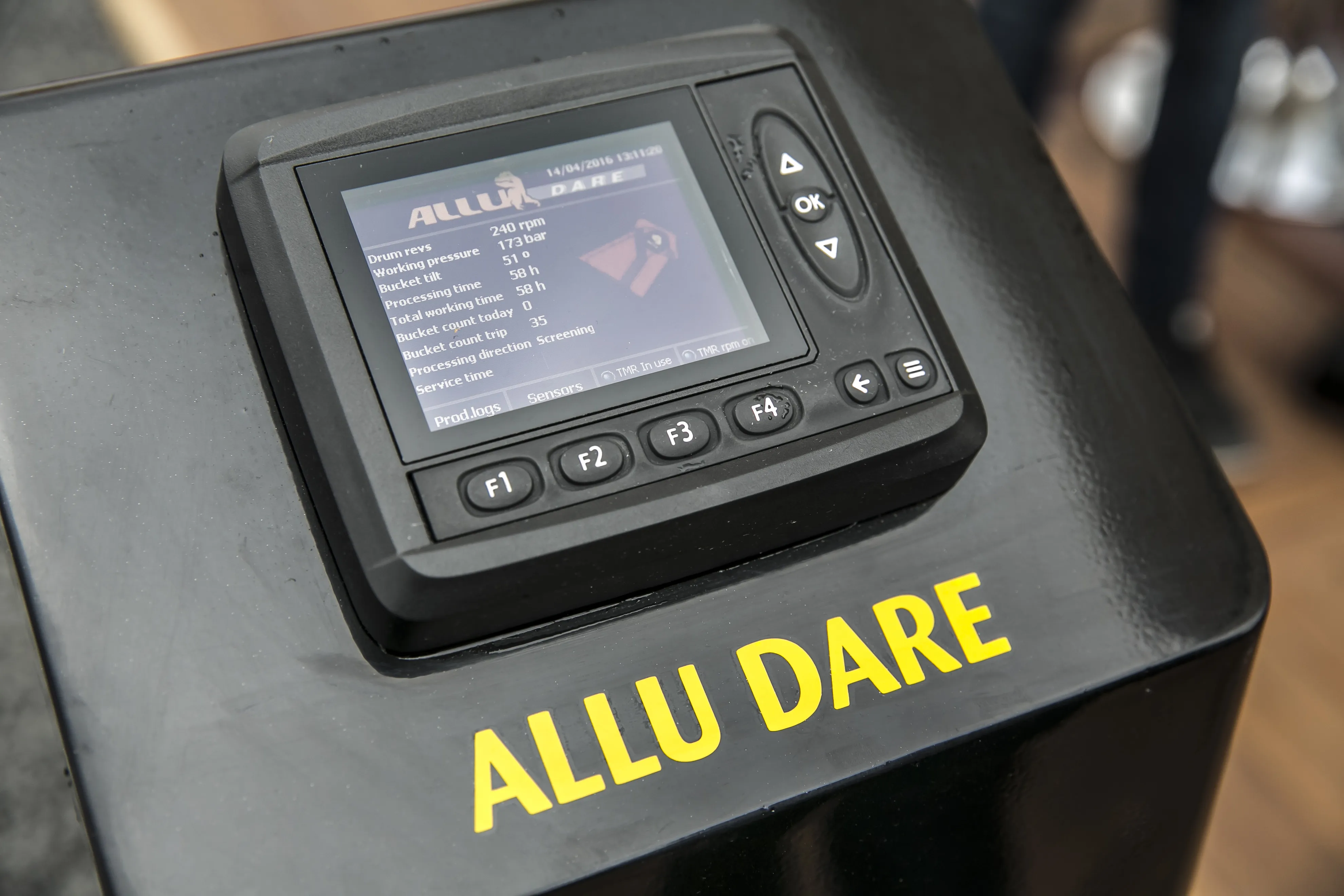

Another exciting innovation on show this week is the new ALLU Dare (Data Reporting) system, helping to deliver efficient working processes through the provision of data from the hydraulic system in real time. ALLU Dare logs data from the carrier, bucket and the actual operation.

Meanwhile, ALLU M-series buckets are said to be specifically designed for the processing and mining industries. The standard ALLU M series range covers 50 - 160tonne excavators and 30 – 90tonne wheeled loaders. Models for bigger carriers are available on request. ALLU M units work in bulk harbours, material depots and mines in different parts of customer operations. The models can be used for crushing and screening materials, re-crushing of different lumped up materials, and primary processing of ore already in the mining cells, minimising transport costs and transport of waste materials.