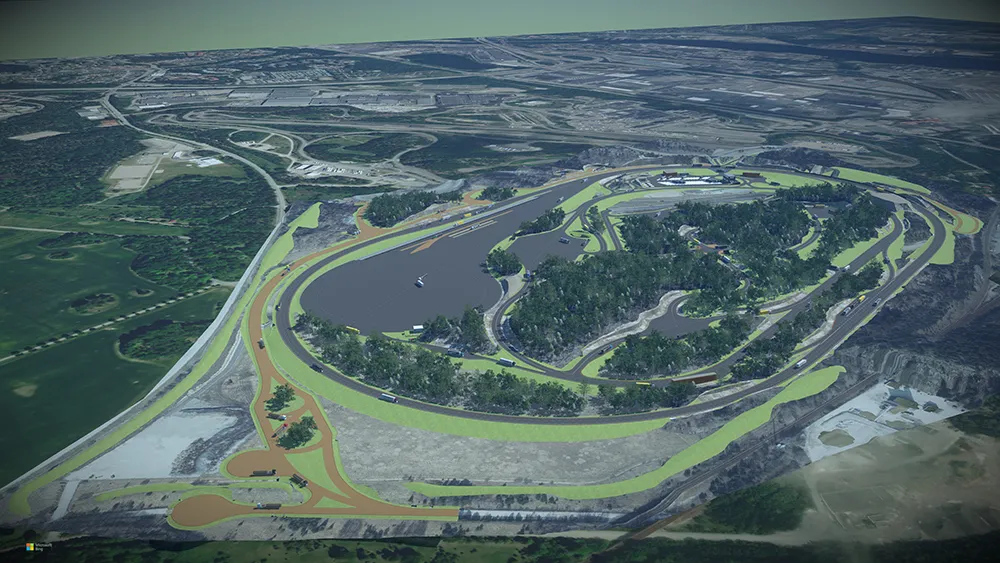

AFRY selected Bentley technology to implement a federated design approach, establishing a collaborative, model-centric, digital project context. The software also provided dynamic relationships between 3D elements so that numerous track design alternatives could be evaluated and modified to ensure constructability. Having 3D models of the different track areas in multiple CAD files, with dynamic relationships maintained, streamlined workflows and analysis of multiple design options.

Utilizing Bentley’s dynamic OpenRoads environment allowed AFRY to perform optioneering and analyze multiple options to determine one with minimal impact to the environment while considering project budget at the same time. With accurate geotechnical data and LiDAR-based digital terrain models, AFRY minimized wastage and optimized mass-balancing and constructability. Compared to updating static 3D elements, progressive digital modeling saved AFRY 30% in time evaluating alternative design solutions. The model-centric approach also reduced drawing production time by 20%, ensured full data consistency, and saved approximately 80 hours on quantities calculations by extracting bill of quantities directly from the models.

Detailed studies of 3D models and animated visualizations in LumenRT digitally revealed few infrastructure clashes and mismatches in road connections during the design stage, eliminating costly errors and rework during construction to save potentially millions of Swedish crowns. AFRY’s dynamic digital approach also balanced earthworks, reducing environmental impact, consistent with the ultimate project goal of lowering the carbon footprint through sustainable transportation. The in-depth testing of vehicles on test tracks prior to manufacturing ensures transport safety and sustainability. The investment in Södertälje will bring direct economic benefits to local and regional Swedish communities. Through innovative digital engineering, AFRY contributed to Scania’s mission of developing autonomous and electrified vehicles to be used globally to improve the environment.

Watch video

Click here for the full case study

Content produce in association with Bentley Systems