Ammann Compaction Expert (ACE), the company’s proprietary automatic measurement, control and documentation system, was first launched in 1998. Several options have been introduced since then for both soil and asphalt applications. The latest version of ACEpro automatically controls and adjusts amplitude and frequency.

It is available for pivot-steered tandem rollers used in asphalt compaction, and single-drum rollers utilised on soil and aggregates.

“All the built-in technology works quietly in the background,” said Josef Dementev, Global Product Specialist Machines at Ammann. “To operators, it appears as a simple system. Yet the technology that seemingly ‘simple’ system brings is a difference-maker on the jobsite.”

The revised version of ACEpro ensures operators can effortlessly access all the system’s technologies.

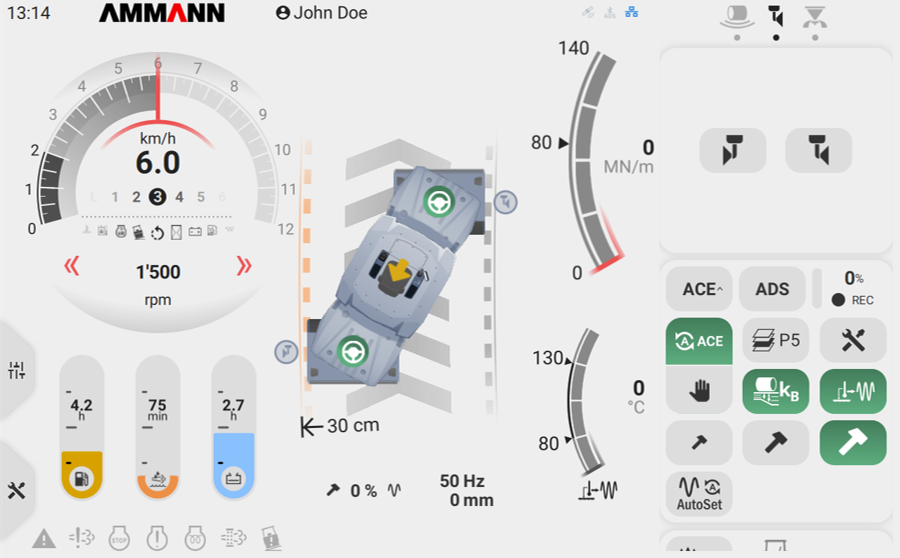

It is fully integrated into the machine’s new 10-inch touch screen, which is attached to the rotating seat and therefore always located directly in front of the operator.

The operator’s seat on the ARP 75 is fully adjustable, with a 270° rotation to optimise visibility from the cab. The machine is equipped with fingertip steering (FTS), making it more operator-friendly and comfortable. The touch screen helps operators control all machine functions simply, safely and quickly, including machine settings, vibratory parameters, lights and the ACE systems.

Several operating modes are available to make the system even more comfortable for all operators, from beginning to advanced levels. From the display, the operator can choose between:

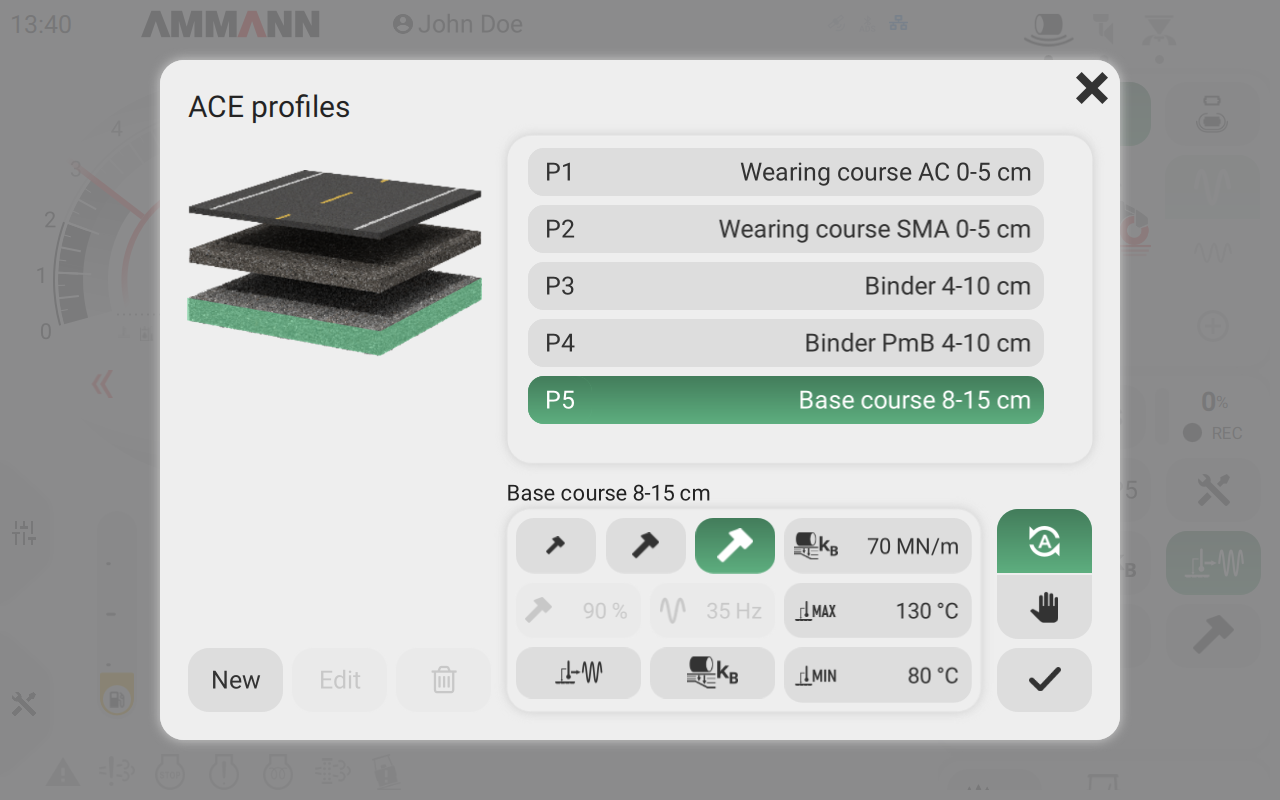

Automatic mode. Vibratory parameters (amplitude and frequency) are automatically controlled and adjusted by the machine. The mode is set based on the compaction target, or selected by the type of materials and layers, in order to reach the target as effectively as possible.

Manual mode. The operator pre-selects parameters (amplitude and frequency) based on their experience or the needs on the jobsite.

User mode. The operator pre-selects the automatic regulation based on prior applications and defined material profiles.

ACEpro is integrated into the main machine display. This means no dedicated displays are needed, which reduces clutter in the cab and ensures clear sight lines for convenience and safety.

The touch screen on the display presents a clear, simple dialogue that leads the operator through the compaction process – in the most efficient way. Straightforward graphics enable effortless monitoring of compaction progress.

Compaction parameters are highly variable for machines equipped with ACEpro. The system fluently regulates the frequency between 38 Hz and 55 Hz, and amplitude from 0 to 0,87 mm (0,035 in).

Automatic frequency and amplitude control is even faster and more precise with this latest version. The technology assesses the actual stiffness of the compacted material and then delivers the optimal compaction force to the ground. This eliminates unnecessary passes and drum jumping and prevents over-compaction or material destruction.

Automatic frequency and amplitude control is even faster and more precise with this latest version. The technology assesses the actual stiffness of the compacted material and then delivers the optimal compaction force to the ground. This eliminates unnecessary passes and drum jumping and prevents over-compaction or material destruction.

Click here to find out more.

Content produced in association with Ammann