The second phase of Hungary’s 265-hectare autonomous vehicle Zalazone test track is nearing completion, according to the minister of innovation.

Laszlo Palkovics said the US$159 million project which started in 2017 is on schedule and progressing in three phases. The track is near Zalaegerszeg, around 180km southwest of Budapest

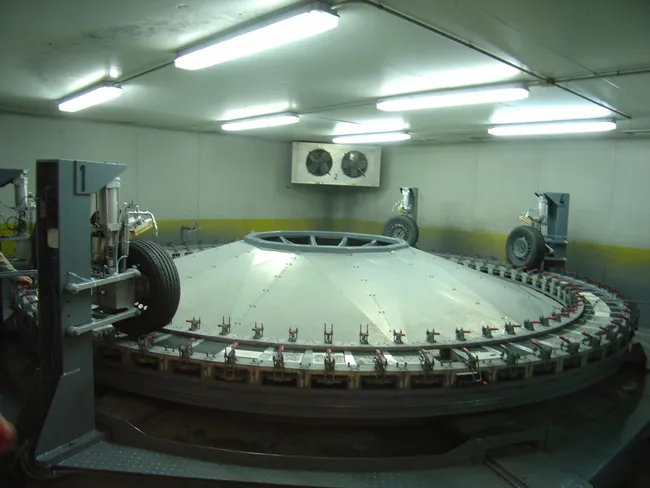

Phase one involved setting up basic elements such a braking platform, a vehicle handling course and a typical country road layout. The braking platform is designed to carry out ABS, ATC and ESP tests along eight types of surfaces and watering systems and also allows for high-speed platooning tests.

Phase one also saw the start of the Smart City area, a city-like area to provide realistic traffic circumstances in a closed area that contains more environmental, traffic, traffic engineering and vehicle dynamic elements.

The second phase, now nearing completion, includes a high-speed oval, bad roads and slopes and additional aspects of the Smart City.

Phase three will be development from 2022 onwards, according to the organisation’s website. It will add more facilities to the Smart City Zone such as more types of lanes, surfaces and road geometry. Different type of building and facades will be placed next to the street grid of Smart City Zone.

Budapest University of Technology, University of Pannonia and Széchenyi Istvány University do much of their vehicular and transportation research at Zalazone.