Xuzhou Heavy Machinery Company, known as XCMG, says its fourth-generation XCT30 on show at INTERMAT 2012 marks a “new level” of the firm’s truck crane manufacturing.

January 6, 2017

Read time: 2 mins

The machine, according to XCMG, incorporates advanced design concepts in its structure and the appearance of its components, to its internal system configuration and performance. XCMG claims the XCT30 is leading a “new development direction” for the truck crane industry, while providing a “technical basis for future exploration” in truck crane development.

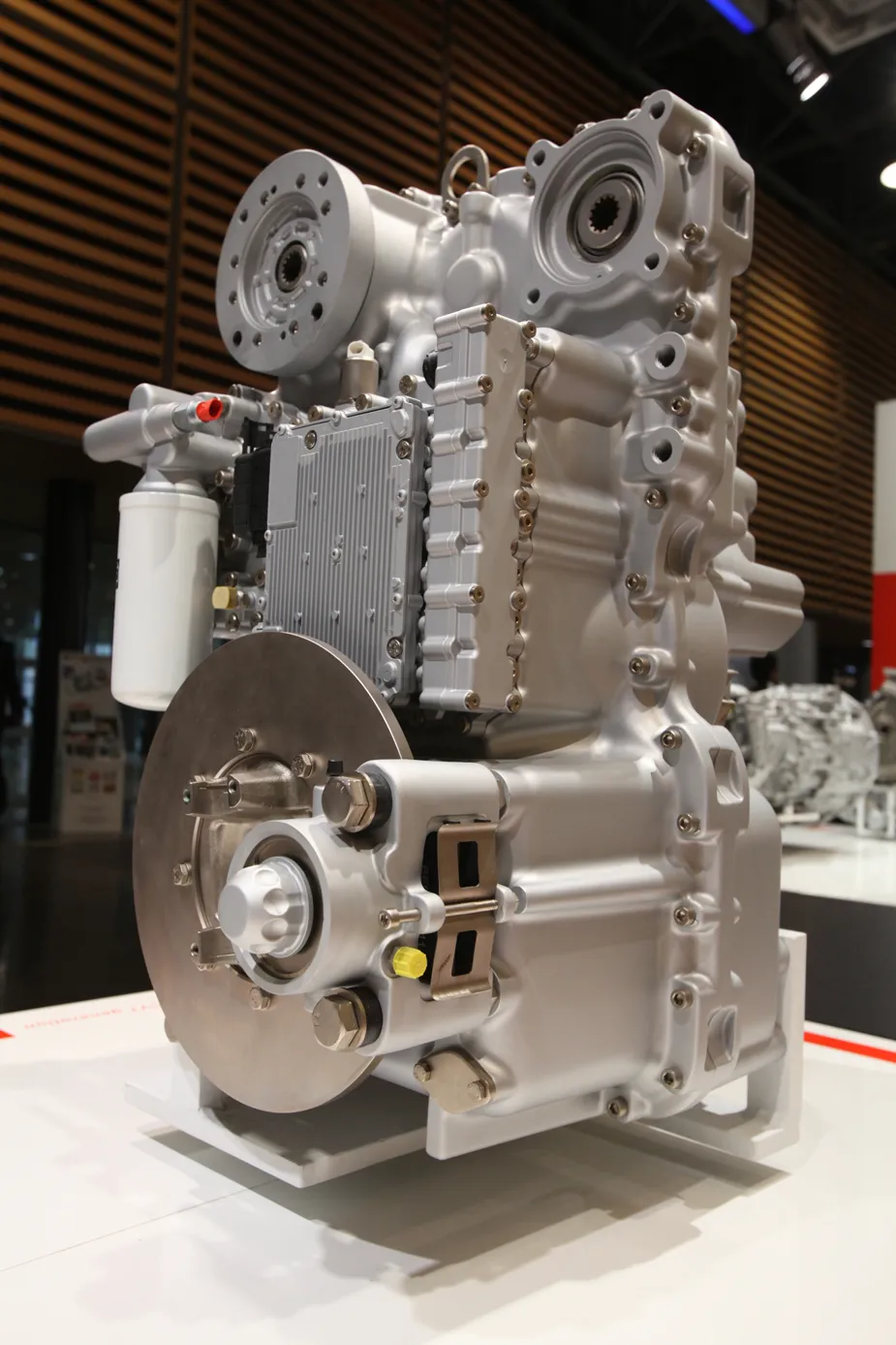

Adopting a tri-axle chassis and five-section boom with twelve cross sections, the XCT30 features a wide operating range and powerful lifting performance. Its small tonnage assistant hoisting mechanism, said to be the first one in China, uses the hitching form to meet strict road regulatory requirements in different regions. Self-developed hydraulic and electrical systems are used to raise operating performance of the complete machine, and to ensure good rotary micro-mobility, high safety, and high fuel efficiency. The application of adaptive dedicated double power curve technology allows fuel consumption savings of 6% for the complete machine, an increase of 5% in operating efficiency, and 5% lower maintenance costs.

Other features of the XCT30 include a

XCMG said the XCT30 meets all European road and regulatory criteria.

%$Linker: