The Finnish company REMU will give a world premiere to its new screening plant. REMU specialises in developing screening plants for topsoil, and it says new re-engineered solutions will increase screening capacity and add value to contractors who are working with different materials from topsoil to compost and many other materials. The function of the screening plant is based on rotating blades. Synchronous movement of blades, made from wear-resistant stainless steel, conveys the oversized material forward

January 6, 2017

Read time: 2 mins

The Finnish company 2405 REMU will give a world premiere to its new screening plant.

REMU specialises in developing screening plants for topsoil, and it says new re-engineered solutions will increase screening capacity and add value to contractors who are working with different materials from topsoil to compost and many other materials.

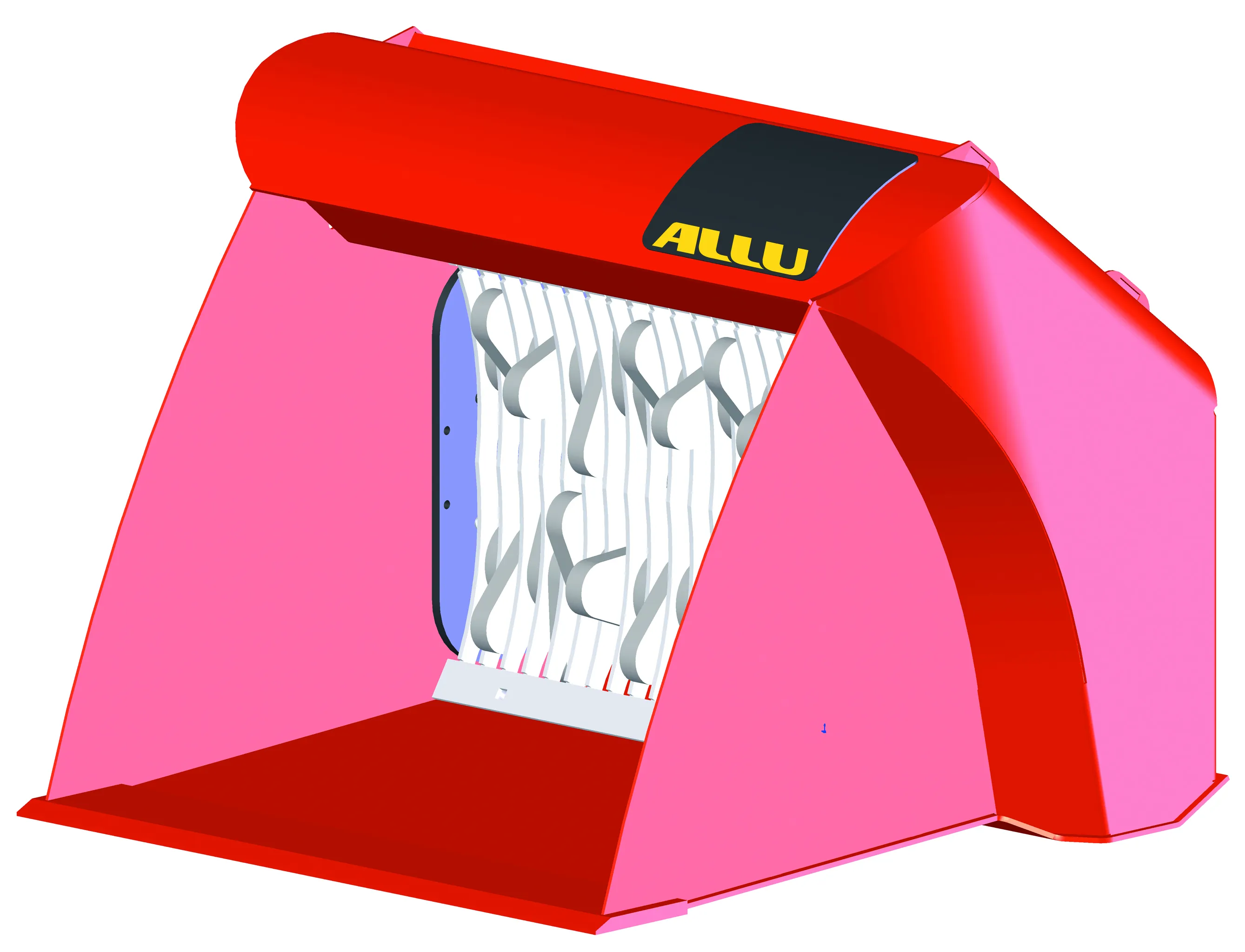

The function of the screening plant is based on rotating blades. Synchronous movement of blades, made from wear-resistant stainless steel, conveys the oversized material forward while fines fall through the screening element.

A totally new machine lay-out of the REMU screening plant is said to offer more efficient site operations with easier and safer maintenance, and its compact dimensions make transport easier, whether skid or track mounted.

Among optional units are a second screening element; fragmentor; magnetic separator; remote controller and fertiliser and limestone feeder.

REMU manufactures screening buckets, plants and Big Floats (also on show) and amphibious excavators, in Ähtäri, Finland, where it has business premises since 1997.

REMU specialises in developing screening plants for topsoil, and it says new re-engineered solutions will increase screening capacity and add value to contractors who are working with different materials from topsoil to compost and many other materials.

The function of the screening plant is based on rotating blades. Synchronous movement of blades, made from wear-resistant stainless steel, conveys the oversized material forward while fines fall through the screening element.

A totally new machine lay-out of the REMU screening plant is said to offer more efficient site operations with easier and safer maintenance, and its compact dimensions make transport easier, whether skid or track mounted.

Among optional units are a second screening element; fragmentor; magnetic separator; remote controller and fertiliser and limestone feeder.

REMU manufactures screening buckets, plants and Big Floats (also on show) and amphibious excavators, in Ähtäri, Finland, where it has business premises since 1997.

%$Linker: