Kobelco Cranes is introducing three brand new heavy-duty cranes in response to global customer demand.

The releases include two new crawler cranes with telescopic booms in the 75tonne class –models TK750S and TK750FS – and one new 120tonne heavy-duty foundation crawler crane with lattice boom; the BMS1200HD. Both the TK750FS and the TK750S are equipped with a 235kW diesel engine to provide the rugged power for the foundation job. This strong engine can also be found in 250tonne lattice boom crawler cranes

January 6, 2017

Read time: 2 mins

The releases include two new crawler cranes with telescopic booms in the 75tonne class –models TK750S and TK750FS – and one new 120tonne heavy-duty foundation crawler crane with lattice boom; the BMS1200HD.

Both the TK750FS and the TK750S are equipped with a 235kW diesel engine to provide the rugged power for the foundation job. This strong engine can also be found in 250tonne lattice boom crawler cranes.

The TK750FS has 208kN (21.2tf) maximum line pull and 107.9kN (11.0tf) rated line pull on the main, auxiliary and third winch, and an operating weight of 74.8tonnes. It also has 153kN (15.6tf) maximum line pull and 68.7kN (7.0tf) rated line pull on the main and auxiliary winch and an operating weight of 69.2 tonnes.

The telescopic crawler cranes of the Kobelco TK750 Series combine the lifting power and high stability of crawler crane models with the excellent performance of an automatic boom extender/retractor.

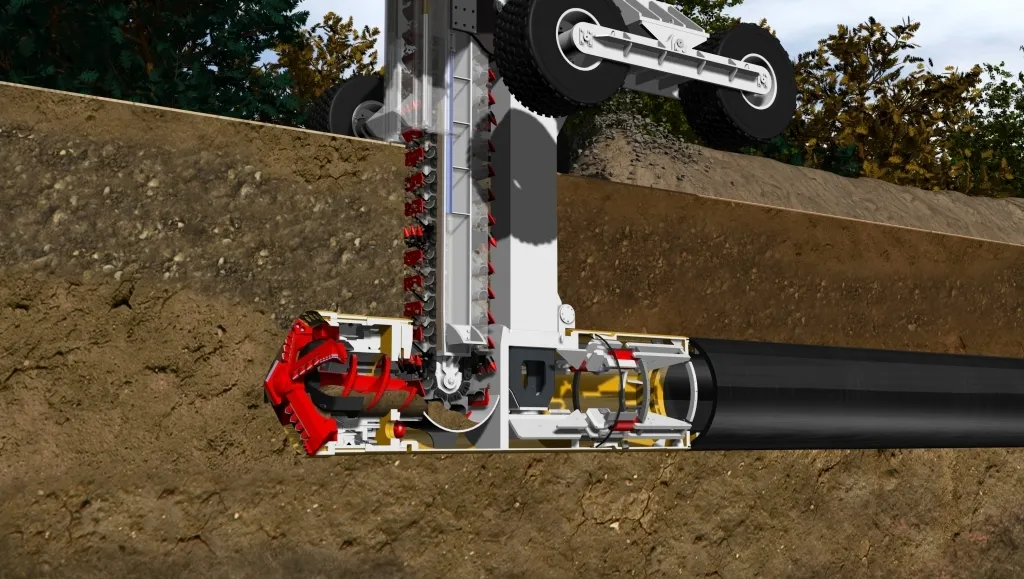

The Kobelco BMS1200HD is a genuine full-stocked heavy-duty foundation machine featuring high-performance winches, 314kN (32.0tf) maximum line pull and 157kN (16.0tf) rated line pull on main winch and auxiliary winch with 36mm diameter wire rope.

Standard line speed on first layer is 110metres per minute, which is twice as fast as its nearest heavy-duty competitor with standard winches.

High spooling capacity makes deep digging possible. This increases the lifetime of wire rope and reduces running cost and downtime as the time to change wire rope is reduced by around 50%. Spooling capacity on the first layer is 54m, nearly 50% higher than some competitors. This means the BM1200HD can continue operations while working on the same layer, while competitors’ machines will have to change layer far more often because of their limited spooling capacity.

Stand: F12 1202/2

%$Linker:

%$Linker: