Goodyear’s new wheeled loader tyre for heavy applications, the RT-5D, is said to offer 25% more carrying capacity, greater comfort and more powerful traction compared to its predecessor. The claim is based on internal assessment at the Goodyear Innovation Centre Luxembourg 2012 in comparison with the RT-5C (tested size, 29.5R25).

April 16, 2013

Read time: 3 mins

The claim is based on internal assessment at the Goodyear Innovation Centre Luxembourg 2012 in comparison with the RT-5C (tested size, 29.5R25).

The tyre, given its world premiere at bauma, is one of two new products launched by the company, which is also highlighting new service-based offerings.

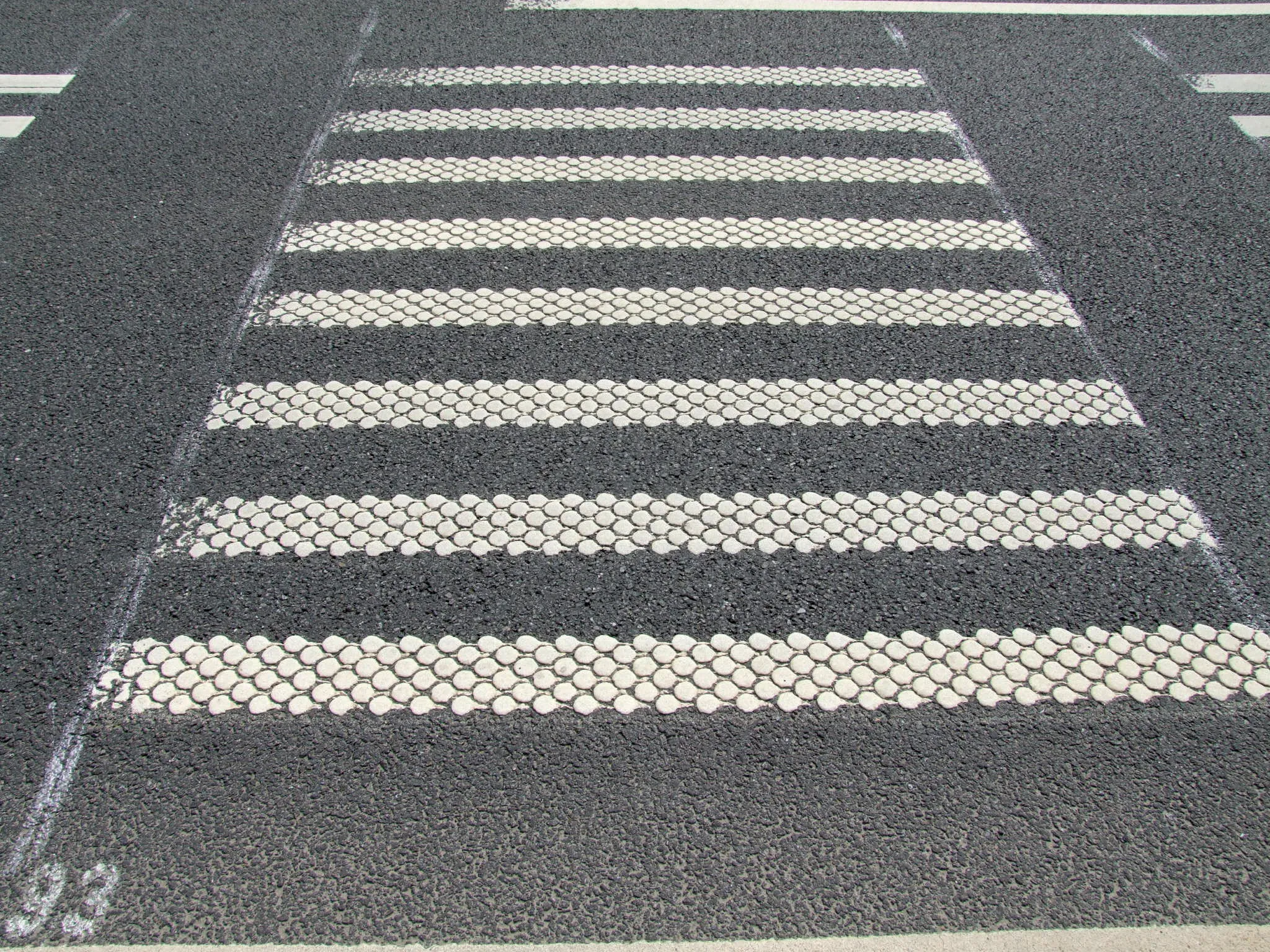

The new addition to Goodyear’s off-the-road tyre range is a level 250 (L5) traction tyre for severe conditions including those in quarries, difficult industrial applications and recycling, as well as in open and underground mines.

The Goodyear RT-5D features hi-stability carcass technology, which combines reinforcements in the bead area, on the carcass breakers and at the ply turn-up.

The innovative CAD-developed tread design is also said to deliver a high level of protection against impact and shocks, as well as its powerful traction performance and longevity, particularly in tough environments such as quarrying.

Compared to the RT-5C, vibrations on hard surfaces are said to be reduced by 30% for far greater comfort.

The company also launched the new EV-4C radial tyre for industrial applications and it is designed to be used mainly on straddle carriers, which are used in most ports around the world.

While the quality and the performance of tyres are essential to maximise the productivity of machinery, incorrect fitments and maintenance will lead to short tyre life, poor performance and, therefore, high cost per hour.

“OTR tyres are a significant investment but without correct maintenance they will not give the expected performance and will not last long either,” said Octavian Velcan, managing director of Goodyear OTR Tyres in EMEA (Europe, Middle East, Africa).

“OTR vehicles and equipment, by their nature, frequently operate not only in hostile conditions but also a long way from tyre service workshops. For this reason we offer our two programmes: Goodyear at your Service and FleetOnlineSolutions Mobile. Something as basic as tyre pressures can make a huge difference to operating costs and we are able to show a customer just what those cost variations are and in the local currency.”

Goodyear at your Service is an internet-based program that offers customers expert support when purchasing and operating Goodyear OTR tyres, and is available to all off-road equipment operators in Europe, while FleetOnlineSolutions Mobile Technical Evaluation (FOS Mte) for OTR customers is also an internet-based tyre management program, which allows fleet inspection reports to be filed on-line when they are carried out. View more videos

View more stories