Bonfiglioli is broadening its range of drives for road construction equipment with a series of new products for use in milling machines, pavers and compactors. The new milling drive for asphalt planers now features a two-stage gear motor with reinforced bearings on the integrated pulley mounting shaft. The technical specifications for this new solution include integrated lubrication that eliminates the need for a system installed in the milling head and maximises lubrication efficiency. There is also an off

January 6, 2017

Read time: 2 mins

Meanwhile a two-speed travel drive gearbox has been developed for paving machines, which comes in addition to the conventional, single speed gearboxes. The existing paver two speed drives in sizes 606-610 have now been joined by the new 611W2-3. This features an in-line architecture and is said to be extremely compact, with a low reduction ratio for high speed machine transfers and a high reduction ratio drive for high torque and traction at the slow travel speeds needed for asphalt paving. The new gearbox suits machines weighing up to 16tonnes when empty, and with transfer speeds of over 20km/h and up to 190kW in installed power.

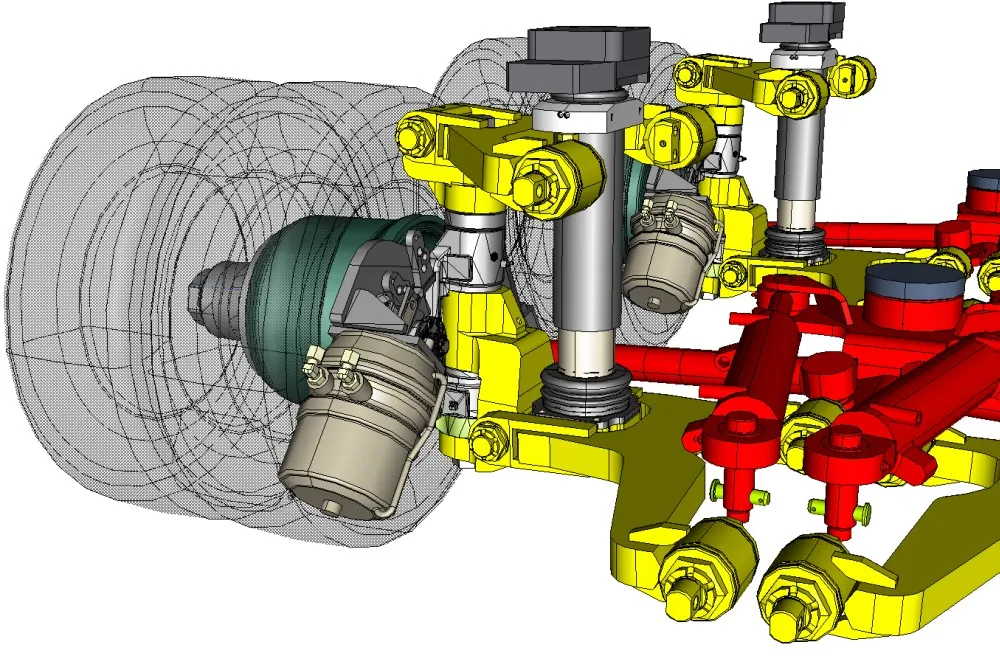

The firm is extending its range of drives for pneumatic tyre compactors. The firm’s recently introduced 600Y Series suits duties on the rear wheels of rubber tyred rollers, featuring an innovative design with two final drives, each of which drives two wheels. The concept greatly reduces maintenance, improves access, optimises the layout of the hydraulic system, and increases the safety and reliability of the machine. The firm is now adding the new 605Y, to complement the existing 606Y and this new system can be used on machines weighing up to 16tonnes.

Stand: A4.117

%$Linker: