New Holland is introducing new models of heavy-duty crawler excavators. The E385C and E485C are in the 35tonne and 48tonne category respectively.

New Holland said that they have been built to deal with the most demanding applications and harshest conditions. The latest models offer more power and fast cycles with new Tier 4 interim engines and new hydraulics. Fuel consumption is improved through the new hydraulics and new ECO working mode.

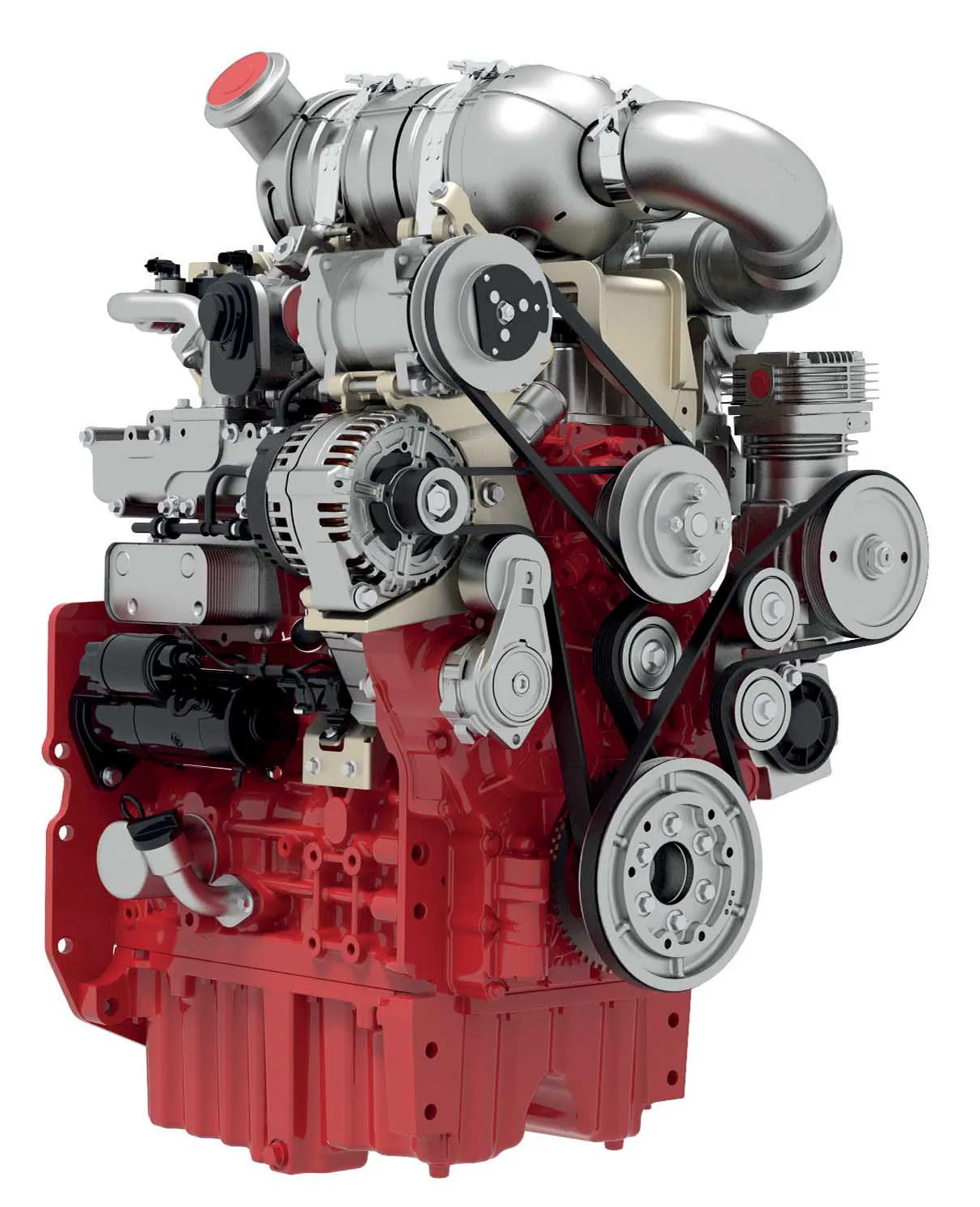

The E385C and E485C crawler excavators feature 286 hp and 363 hp engines respectively and meet the strict Tier 4 interim emissions standards with Cooled Exhaust Gas Recirculation (CEGR) technology. The CEGR system is fully integrated into the design of the two new models.

The Hydrotonic system combines electronic technology with a hydraulic system and has been designed to maximise the machines’ performance according to the job being carried out.

The company said that the high efficiency of the hydraulics ensures 100% pump usage in all applications. The hydraulic design has been developed to minimise friction losses and pressure drops, economising on fuel.

The upgraded New Holland Advanced Electronic Processor introduces a new ECO working mode for optimised fuel consumption. The control monitor puts the operator in control of the efficiency of the machine’s performance, with the fuel economy meter showing the hourly consumption and the ECO Icon indicating when the machine is operating most efficiently.