Volvo Penta is introducing start/stop technology that could cut fuel bills by 5% by turning off engines when they are left idling. Such systems have become increasingly common of late in private cars, where they stop the engine while waiting in a queue or at a red traffic light.

January 6, 2017

Read time: 2 mins

Such systems have become increasingly common of late in private cars, where they stop the engine while waiting in a queue or at a red traffic light.

Volvo Penta is now incorporating the functionality into industrial engines. Fuel can represent up to 90% of the life-time operating costs in applications such as construction, making a 5% saving extremely valuable said Volvo Penta.

When the machine’s engine is idling it is turned off after a pre-set time – usually five to 10 seconds. The engine then restarts immediately once the driver activates any of the machine’s controls, allowing work to continue.

The automatic start/stop function is an optional accessory and in operation it can be deactivated or reactivated when needed.

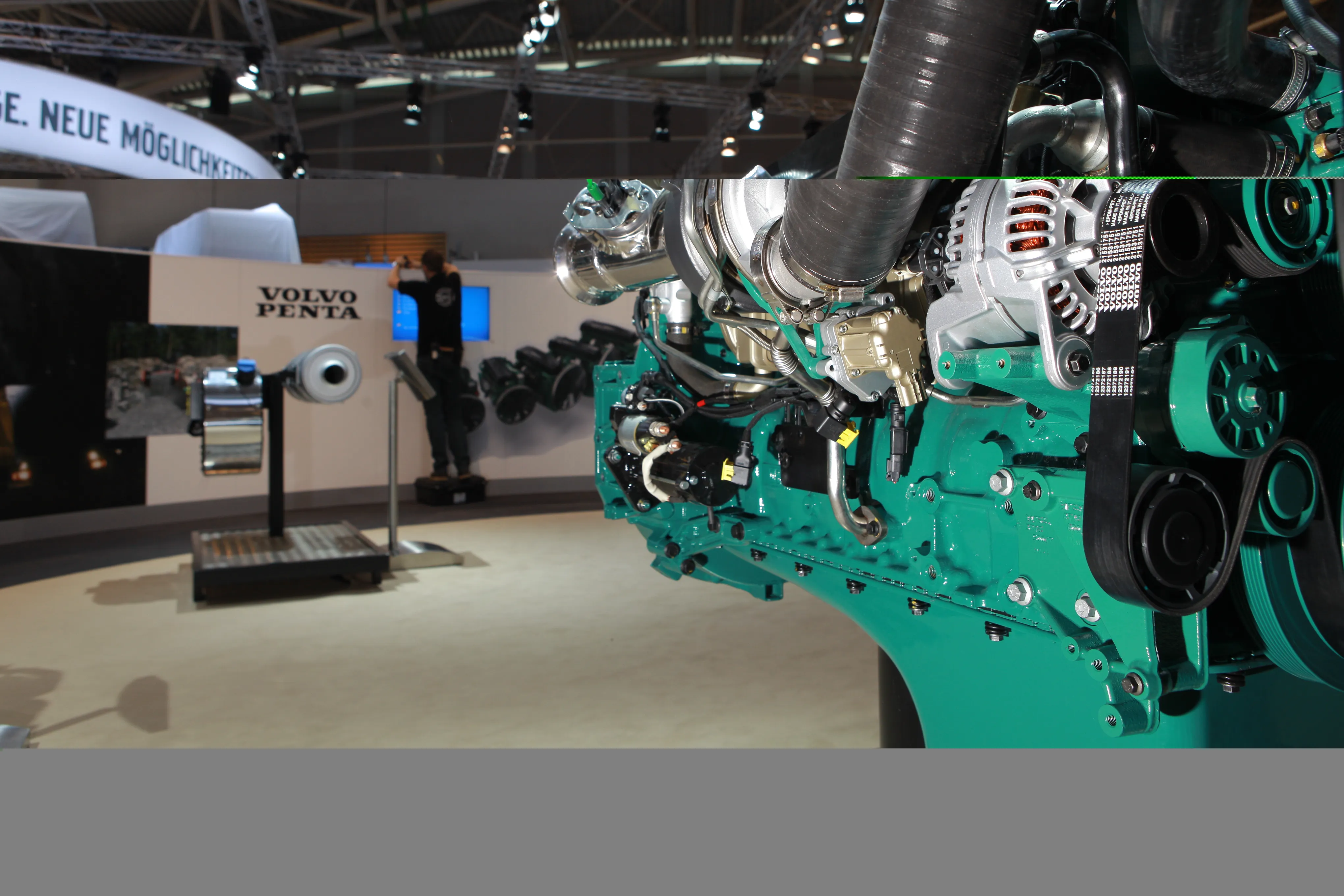

Volvo Penta used bauma to introduce its new Tier 4 Final engine range for off-road applications. The range consists of five basic engines. Volvo Penta’s technology choice for the new emission stages is the SCR system used extensively within the Volvo Group.

Stand: F5.512/514

%$Linker: