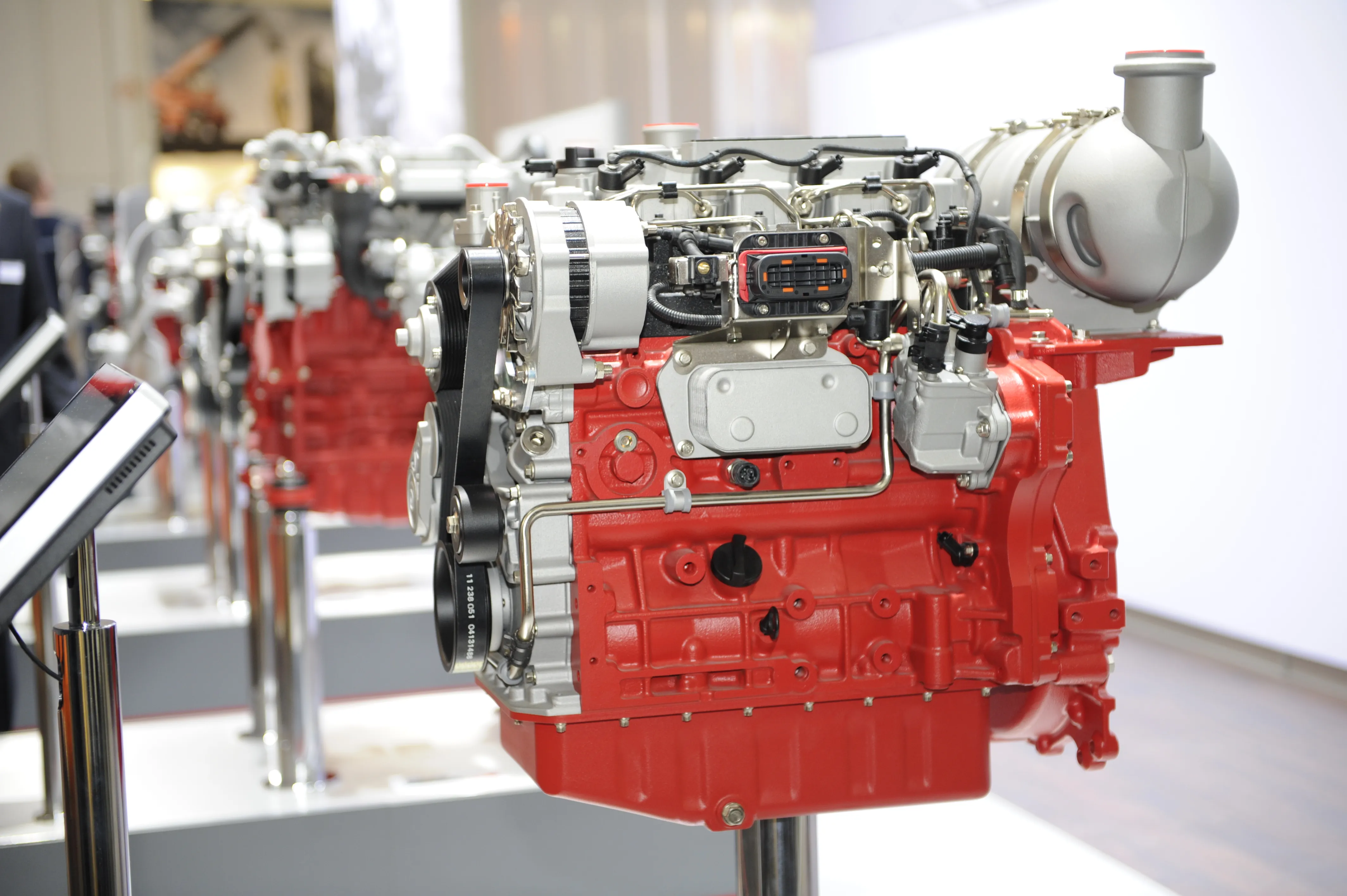

With intelligent emissions control from the introduction of a Cummins six-cylinder engine, Vogele’s Super 2100-3i paver aims to raise paving efficiency to another level.

January 6, 2017

Read time: 2 mins

%$Linker: 2 Internal 2 4802 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">RSS</span></span> Road Paving and Recycling false /event-news/intermat-2012/rss/road-paving-and-recycling/ true false %>With intelligent emissions control from the introduction of a 196 Cummins six-cylinder engine, 1194 Vögele's Super 2100-3i paver aims to raise paving efficiency to another level.

The Dash 3 paver series gets EcoPlus - a package aimed at making significant reductions in fuel consumption and noise levels.

A switchable transfer gearbox allows hydraulic pumps to be by-passed when they are not needed. A variable-speed fan is another example of energy efficiency, whose speed is tweaked according to charge air, coolant temperature and hydraulic oil temperature.

Vögele Super 2100-3i operators also get a revised platform with a larger colour display. AutoSet enables the paver to be moved quickly and easily on the job site. At the push of a button, hopper sides and the hydraulic hopper front are folded up, the deflectors in front of the tracks are raised, the augers moved into their uppermost position and the screed is raised and locked in place.

An automatic docking function called PaveDock, is another new feature on the Super 2100-3i. It absorbs impacts from the feeder, and any lorry movements required during the feeding process are communicated to the lorry driver using a set of signals.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The Dash 3 paver series gets EcoPlus - a package aimed at making significant reductions in fuel consumption and noise levels.

A switchable transfer gearbox allows hydraulic pumps to be by-passed when they are not needed. A variable-speed fan is another example of energy efficiency, whose speed is tweaked according to charge air, coolant temperature and hydraulic oil temperature.

Vögele Super 2100-3i operators also get a revised platform with a larger colour display. AutoSet enables the paver to be moved quickly and easily on the job site. At the push of a button, hopper sides and the hydraulic hopper front are folded up, the deflectors in front of the tracks are raised, the augers moved into their uppermost position and the screed is raised and locked in place.

An automatic docking function called PaveDock, is another new feature on the Super 2100-3i. It absorbs impacts from the feeder, and any lorry movements required during the feeding process are communicated to the lorry driver using a set of signals.

%$Linker:

Hall: 4 Stand: F012

%$Linker: