The German construction machine manufacturing association, VDMA, is playing a key role in ensuring the simplification of digital communication of construction machines. The MiC 4.0 working group is an association of leading companies from the VDMA and HDB associations and aims to deliver better digital communications for the construction machinery market.

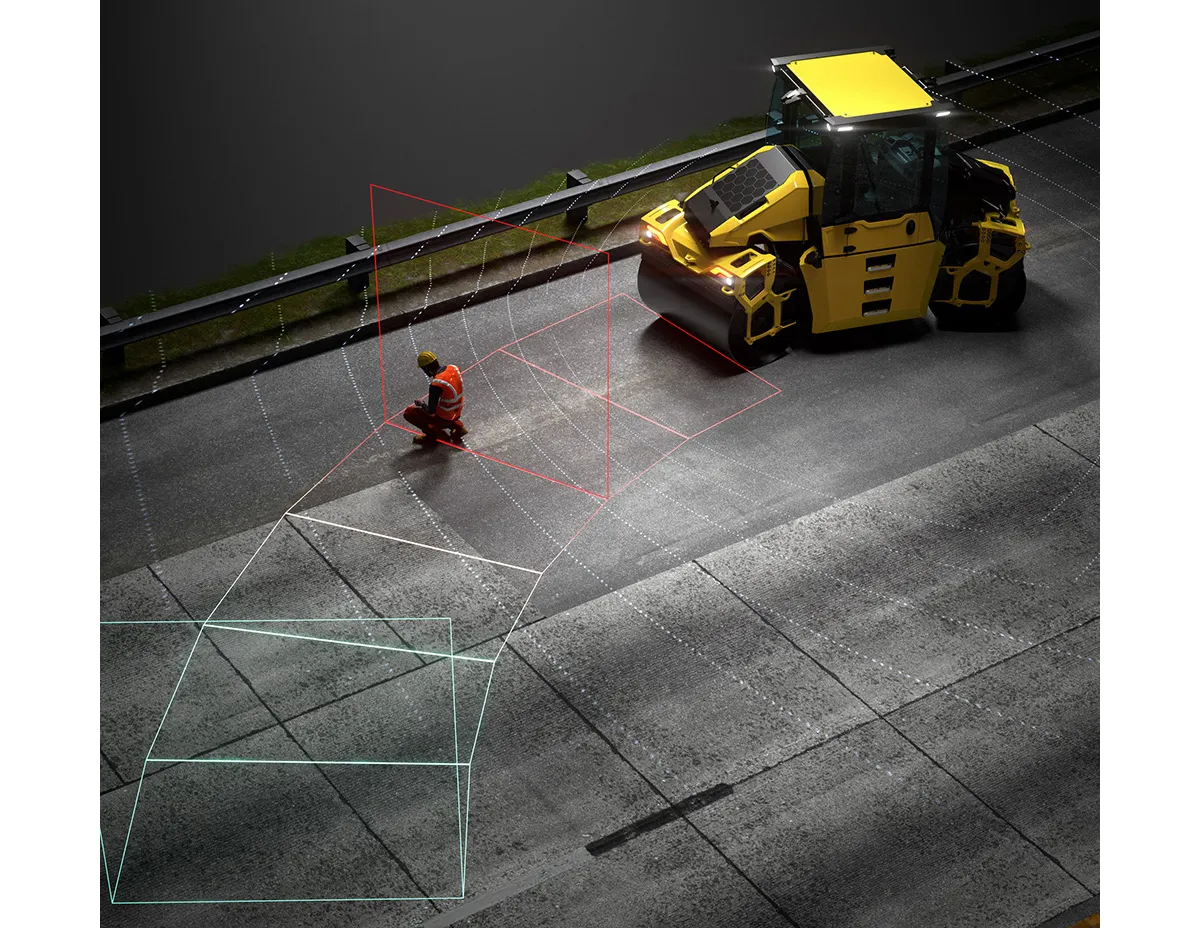

The work will apply to construction machines and attachments and systems and be achieved through cross-manufacturer standards. According to the VDMA, the focus is on immediate benefits for users, with greater transparency, compatibility and efficiency on the construction site.

The MiC 4.0 Guideline explains key developments and applications. The MiC 4.0 TestTool for machine manufacturers can be used by OEMs to check whether their machines comply with the MiC 4.0 requirements in accordance with ISO 15143, a crucial step towards interoperability. The open MiC 4.0 database shows which manufacturers have tested which machine types and what data is available for each. The MiC 4.0 BUS for attachments is a standardised data protocol that enables automatic attachment recognition, without additional displays, software adjustments or hardware changes.

This results in specific advantages for construction machine operators, construction companies and system providers. It reduces effort when changing machines and attachments, allowing improved data integration and clearly defined interfaces for networked construction site processes.