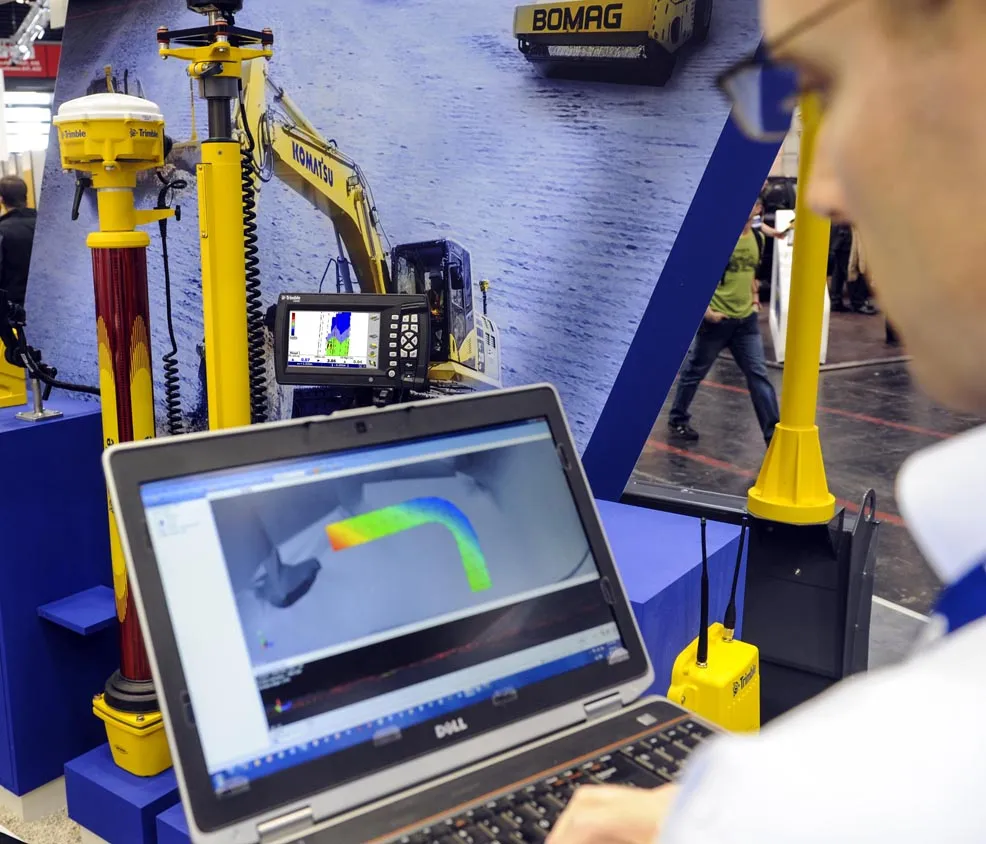

Trimble is demonstrating its sophisticated Connected Site portfolio for heavy civil contractors, which connects assets, information, people, machines and sites. This package can meet a vast array of workflow needs of different stakeholders within the contractor’s organisation and meets demand for greater efficiency, shorter completion times and higher quality. Trimble is demonstrating how its Connected Site solutions leverage real-time wireless data flow between the office and job site. This technology allo

January 6, 2017

Read time: 3 mins

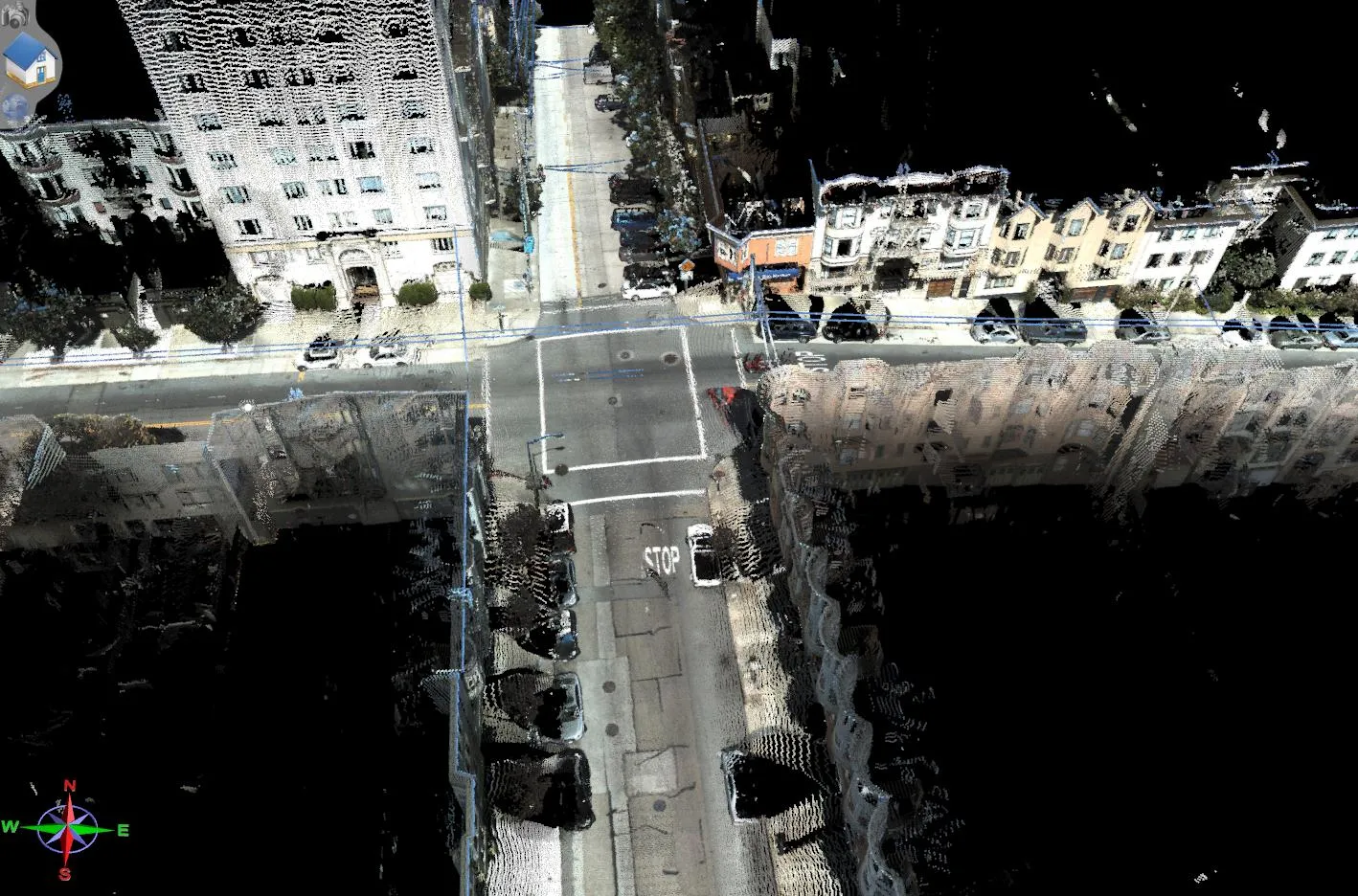

Trimble is demonstrating how its Connected Site solutions leverage real-time wireless data flow between the office and job site. This technology allows design engineers, contractors and job site crews to tackle grading and excavation jobs by providing workflow integration from the design phase through to the finished project. According to Trimble, contractors can achieve faster project completion, while reducing costs, improve safety and reduce environmental impact.

For the Connected Controller, Trimble is giving demonstrations of real-time, two-way data flow between the office and field handheld mobile devices using GPS or total station positioning systems used for staking, grade checking, site supervision, or inspection of work. The takeoff and data preparation tasks can be carried out using the Business Center – HCE system, and design files sent wirelessly to the controller in the field. Eliminating trips back to the office to retrieve or download the latest design and work order data streamlines the process and enables field crews to have up-to-date information, reducing downtime.

Similarly for the Connected Machine, Trimble’s demonstration highlights productivity improvements from real-time, two-way data for on-machine grade control systems though a live link between the machines and the office. The live link allows contractors to send up-to-date design information from Business Center – HCE to the cab, eliminating the risk of errors associated with use of incorrect or out-of-date site models. Two-way data also allows the equipment manager to connect assets remotely and use VisionLink powered by Trimble to monitor site production volumes, compaction performance, and equipment productivity and utilisation.

The Connecting People demonstration of the Connected Community uses the Internet to integrate head office, site office and field crew operations in a communication portal. This can then be accessed by construction project stakeholders to exchange project-related information. The Connected Community can provide insight into project operations, head office activities and provide a collaboration site that allows efficient sharing of information and rapid resolution of site problems and requests for information. The collaborative environment boosts efficiency, and reduces delays associated with communicating and sharing information with multiple stakeholders on the construction site.

Stand: A3.327/426

%$Linker: