Trimble and Manitowoc Cranes are collaborating on developing technology that boosts construction lifting industry productivity, while improving onsite crane use and data management.

February 1, 2012

Read time: 2 mins

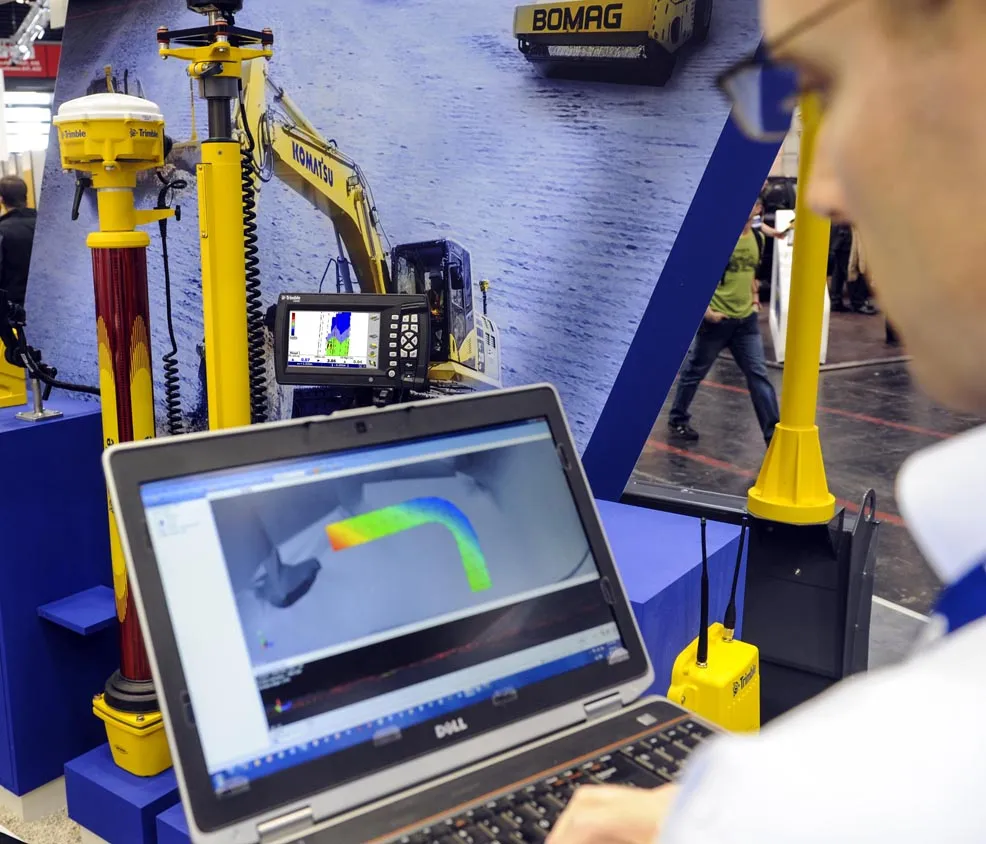

The firms said their recently-struck deal would see the creation of an IT solution that provides real time, centimetre-level positioning data for multiple cranes on the same construction site. It will measure crane position in absolute coordinates using rugged, easy to install, non-contact sensors that can be installed on both fixed and mobile cranes. In-cab displays of cranes fitted with the solution will allow operators to view the site, multiple working crane zones, forbidden zones, target locations and other site data.

In addition, Trimble and Manitowoc Cranes are developing an ‘Intelligent Environment’ database for the solution capable of receiving constant updates of data from Building Information Modeling (BIM) tools and other site sensors working in tandem. Enabling a user to programme an alarm or even halt crane operation upon detection of unplanned work activity on the construction site is due to be among the solution’s features.

To enhance jobsite awareness and management, a wireless local area network (WLAN) will share the crane position information across the construction site, providing each crane operator, the lift scheduler, and even the back office (if the Internet connectivity option is enabled) instant status against the BIM plan. It will enable informed, exception-based decisions to be made in real time.

"Manitowoc is committed to providing the most advanced and comprehensive range of lifting solutions," said Bob Hund, Crane Care executive vice president for Manitowoc Cranes.

"Working together with Trimble allows us to access market leading technology to collaborate to develop innovative tools to increase crane operator awareness on a construction site."

John Cameron, general manager of Trimble's Integrated Technologies Division, said: "By partnering with the Manitowoc Cranes, a lifting industry leader, we expect to co-develop solutions capable of lifting and delivering materials on the construction site similar to a contract manufacturer who uses a pick-and-place machine to build an electronic circuit board. Our goal is add crane productivity as another key component of the connected site.”

%$Linker:

%$Linker:

Hall: 5a Stand: H078

%$Linker: