“What is typically used is a car [fitted with road surface profiling technology] that needs to keep stopping when scanning a road surface profile. On larger highways, this has meant the road needs to be closed,” said Achiel Sturm, Topcon’s marketing manager.

“The RTP-300 can scan the road from any vehicle at 105kmh. The highway does not need to be closed and you get clean data. It is way quicker.”

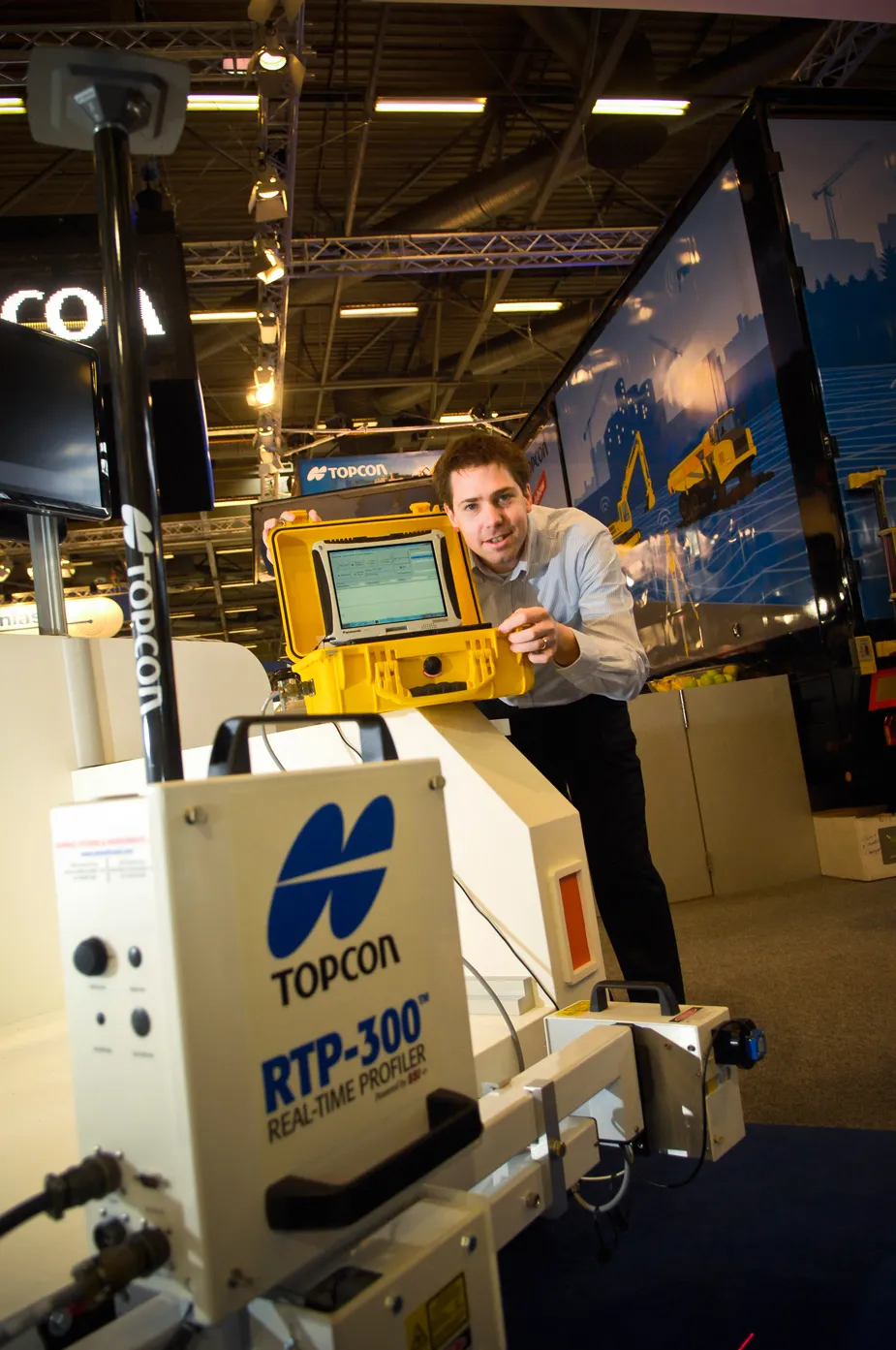

Data collection is achieved by the RTP-300 using a Topcon GNSS dual-constellation satellite receiver system, three laser profilers, wheel encoder technology and a comprehensive computer data collection system.

The RTP-300 system is also capable of producing industry standard reports such as PRI and IRI.

The corrected design data is said by Topcon to be useable on a paver, profiler or any machine control system to provide exact road data at every step of a construction project.

%$Linker:

Hall: 5A Stand: J111

%$Linker: