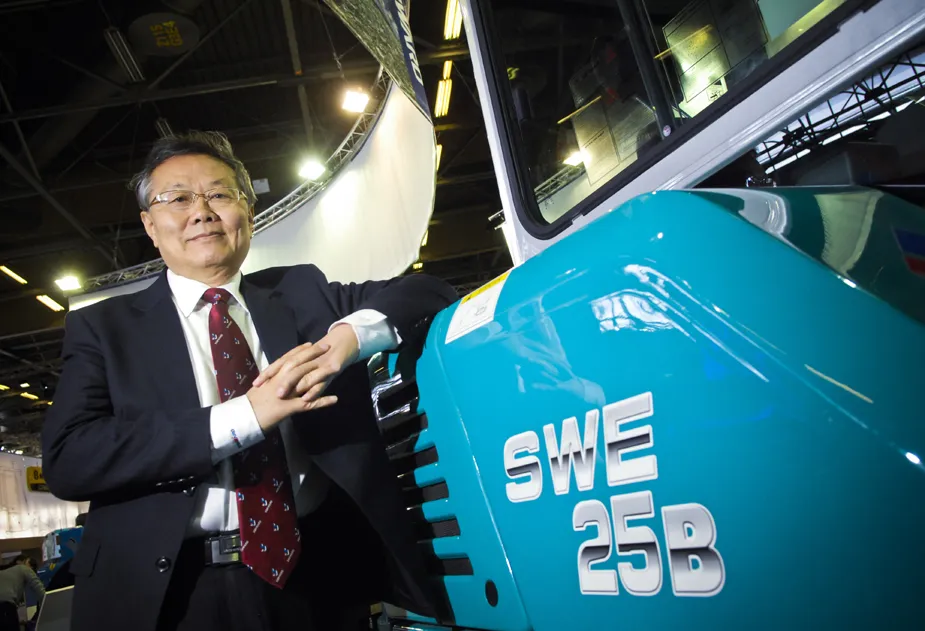

Sunward is keen to further develop its dealership coverage within Europe, which the firm sees as being crucial to increasing its sales. The company is already present in the European market and is actively boosting its profile, as Dr He Qinghua, chairman of the Sunward Equipment Group and also director of the company’s research and development centre, explained. He said, “We have some dealers in Europe and we are planning to enlarge the number of them.”

January 6, 2017

Read time: 2 mins

The company is already present in the European market and is actively boosting its profile, as Dr He Qinghua, chairman of the Sunward Equipment Group and also director of the company’s research and development centre, explained. He said, “We have some dealers in Europe and we are planning to enlarge the number of them.”

Sunward has been raising its profile in Europe for some years and Dr Qinghua said, “We have already started exporting the mini excavators to Europe.”

Mini and midi excavators (both standard and zero tailswing models) are amongst the products the firm is focussing on marketing in Europe, as well as skid steer loaders and tracked loaders. However it has also shown its crawler excavators in Europe and offers a range of machines weighing up to 47tonnes.

So far the firm has sold machines in several European countries including Finland, Germany, Italy, Poland and Sweden. The sales into Germany have been a particular success, as the firm knows this market is very quality conscious. “We found dealers there and they are very satisfied with the products. They tested the machines for a long period and very thoroughly,” said Qinghua.

%$Linker:

Hall: 5A Stand: G169

%$Linker: