SK Solutions claims its Navigator technology incorporates the world’s most advanced universal 3D anti-collision software, preventing potentially lethal accidents on construction sites.

January 6, 2017

Read time: 2 mins

Packaged in a rugged military grade computer for machine installation, its software incorporates GSM2Mobile, a suite of mobile device applications, and Asteroid, a state of the art ERP (Enterprise Resource Planner) that integrates an all-purpose business intelligence tool.

The Navigator uses an advanced form of artificial intelligence (AI). According to information given by sensors, such as machine positions, their speed, weight and inertia, and wind speed and direction, the application calculates a dynamic and temporal safety area called “dynamic and temporal safety cocoon”. The on-board radar identifies its risk environment: the whole neighbouring safety cocoons formed by other mobiles and motionless obstacles.

The system then estimates the collision risk and takes all the corrective measures, via its automatic pilot, to avoid any potential intersection between the mobile’s cocoon and neighbouring cocoons.

A calculation of risk module estimates the collision risk of the mobile and sends it to the decision expert system which, if necessary, starts a collision avoidance process.

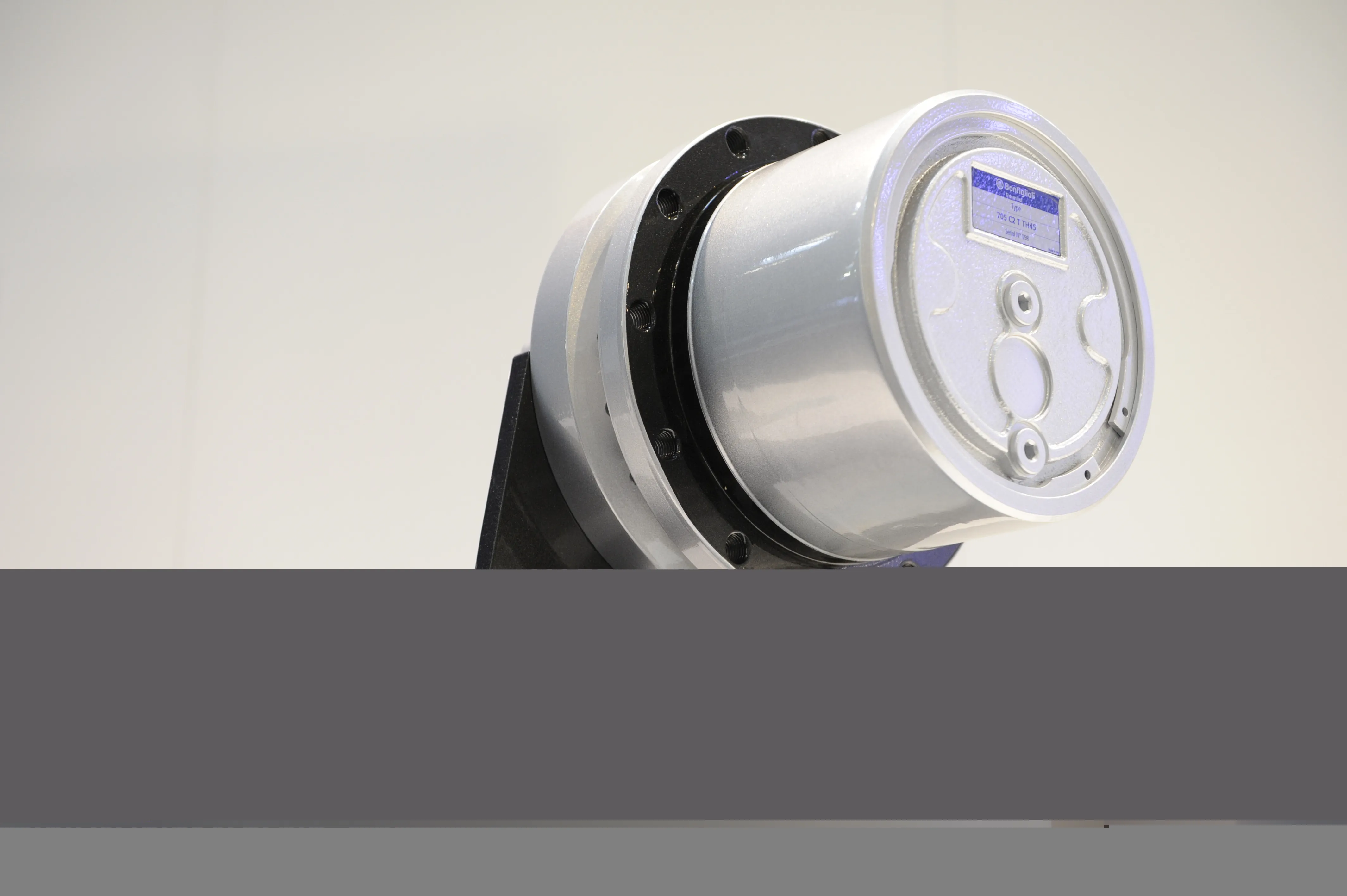

The systematic integration of aerospace components, according to Dubai-based SK, makes the Navigator “revolutionary” in its market.

Last year, SK Solutions and its affiliate SK Saudi Arabia equipped more than 80 cranes with Navigator technology at the King Abdullah Financial District in Riyadh, Saudi Arabia, one of the world’s biggest construction sites.

%$Linker:

Hall: 5A Stand: L037

%$Linker: