After two years of research and development, attachment manufacturer Simex has launched the VSE 40, a screening bucket with a patented mechanism that allows the operator to change the size of the screened material from the cab at the touch of a button. All similar products require eight to 10 hours’ work to change the setting, according to Simex’s assistant general manager Fereico Tamburri. “After we introduced our crushing bucket, we visited lots of crushing sites and found out that for all the screening b

April 15, 2013

Read time: 2 mins

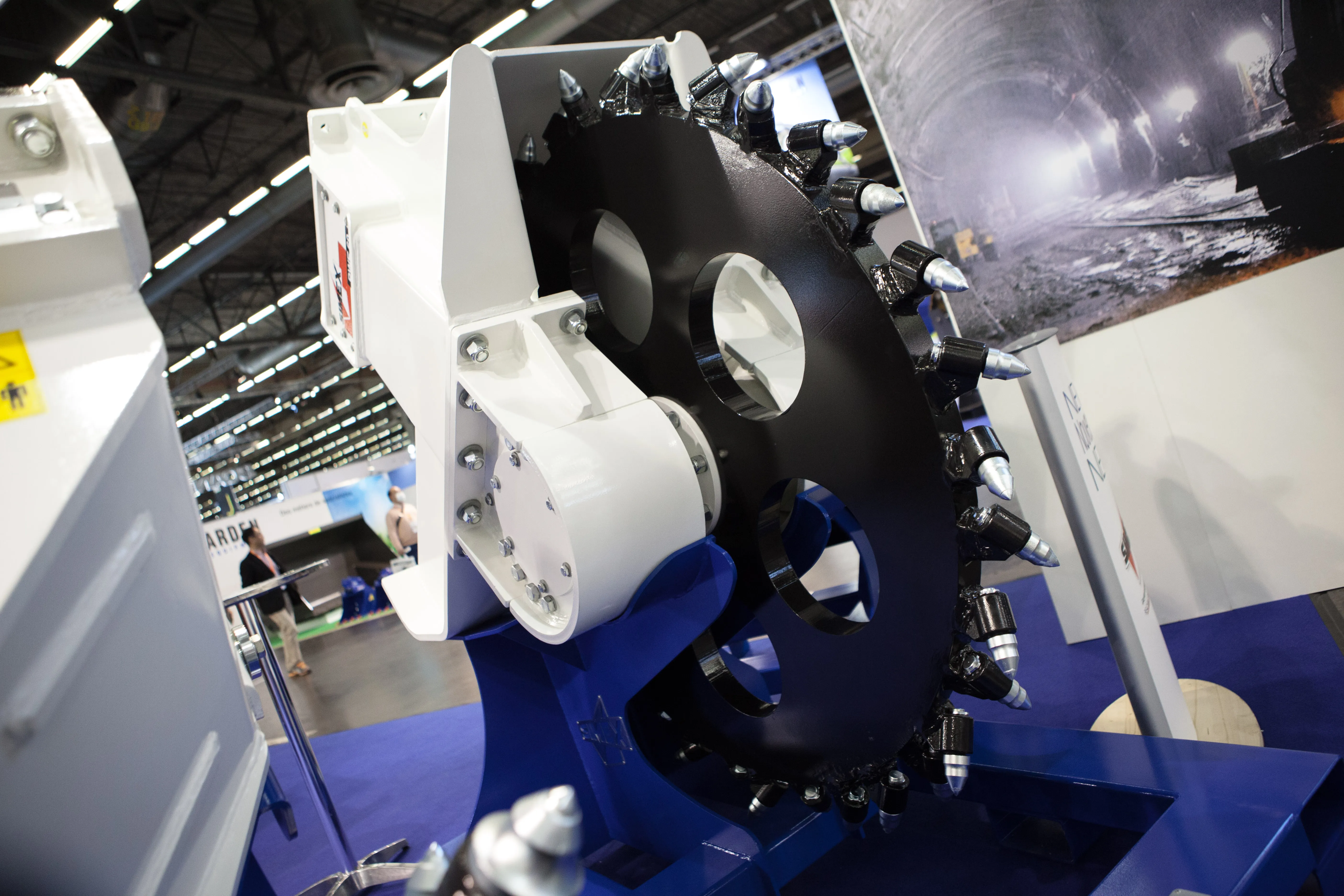

After two years of research and development, attachment manufacturer 1141 SIMEX has launched the VSE 40, a screening bucket with a patented mechanism that allows the operator to change the size of the screened material from the cab at the touch of a button.

All similar products require eight to 10 hours’ work to change the setting, according to Simex’s assistant general manager Federico Tamburri.

“After we introduced our crushing bucket, we visited lots of crushing sites and found out that for all the screening buckets on the market it was difficult to change the configuration to vary the size of material being screened,” said Tamburri. “It’s a long and expensive process, which means that mostly people never change the configuration.”

The VSE 40’s patented technology relies on two outer shafts, which can be moved in and out to lessen or increase the distance from a central shaft. “It took a long time for us to get the mechanism just right,” said Tamburri. “But after 500 hours of testing, we are very happy with the results.”

Designed for excavators between 24 and 35tonnes, the first VSE 40 will leave the production line in the second half of this year.

Simex, which is based in Italy, has increased its exports steadily over the past five years with 85% of its turnover now coming from overseas sales. The Middle East, North America, Australia and New Zealand are all strong markets for Simex, with Tamburri working to open up new markets in the Philippines and Singapore.

Simex’s business is based around developing new technologies. This means that patents play an important part in Simex’s strategy. “As a philosophy, we never copy products from other manufacturers,” said Tamburri. “Patenting and defending patents against possible infringement is not a cost to us, it’s an investment. I emphasise that very strongly.”

All similar products require eight to 10 hours’ work to change the setting, according to Simex’s assistant general manager Federico Tamburri.

“After we introduced our crushing bucket, we visited lots of crushing sites and found out that for all the screening buckets on the market it was difficult to change the configuration to vary the size of material being screened,” said Tamburri. “It’s a long and expensive process, which means that mostly people never change the configuration.”

The VSE 40’s patented technology relies on two outer shafts, which can be moved in and out to lessen or increase the distance from a central shaft. “It took a long time for us to get the mechanism just right,” said Tamburri. “But after 500 hours of testing, we are very happy with the results.”

Designed for excavators between 24 and 35tonnes, the first VSE 40 will leave the production line in the second half of this year.

Simex, which is based in Italy, has increased its exports steadily over the past five years with 85% of its turnover now coming from overseas sales. The Middle East, North America, Australia and New Zealand are all strong markets for Simex, with Tamburri working to open up new markets in the Philippines and Singapore.

Simex’s business is based around developing new technologies. This means that patents play an important part in Simex’s strategy. “As a philosophy, we never copy products from other manufacturers,” said Tamburri. “Patenting and defending patents against possible infringement is not a cost to us, it’s an investment. I emphasise that very strongly.”

Stand: B3.222

%$Linker: