With a production of some 2,000 units in 2012 subdivided into 65 models produced in more than 210 versions, Simex today exports about 80% of its own production. Born in 1991 in San Giovanni in Persiceto, Emilia Romagna, the company soon set about achieving its goal of manufacturing high quality equipment for earth moving prime movers. Starting with asphalt planers for backhoe loaders, asphalt and concrete planers were soon manufactured by Simex for skid steer loaders too.

April 8, 2013

Read time: 2 mins

With a production of some 2,000 units in 2012 subdivided into 65 models produced in more than 210 versions, 1141 SIMEX today exports about 80% of its own production.

Born in 1991 in San Giovanni in Persiceto, Emilia Romagna, the company soon set about achieving its goal of manufacturing high quality equipment for earth moving prime movers. Starting with asphalt planers for backhoe loaders, asphalt and concrete planers were soon manufactured by Simex for skid steer loaders too.

The Simex product range evolution continued with the successful manufacturing of wheel saws, wheel compactors, snow blowers and planers for the excavator arm; all of these products were born to be used in canalisation and road maintenance jobs. Simex has gone on to take its place among the European market leaders in this very niche field.

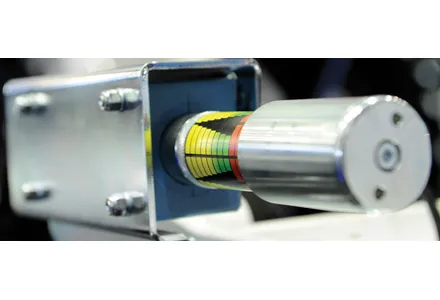

Latterly, Simex has produced rotary cutters for excavator arms. The firm’s eight rotary cutter models can be attached to excavators weighting from 1.5 up to 60tonnes and are suitable for quarry jobs, controlled demolitions, and deep trench works.

2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Born in 1991 in San Giovanni in Persiceto, Emilia Romagna, the company soon set about achieving its goal of manufacturing high quality equipment for earth moving prime movers. Starting with asphalt planers for backhoe loaders, asphalt and concrete planers were soon manufactured by Simex for skid steer loaders too.

The Simex product range evolution continued with the successful manufacturing of wheel saws, wheel compactors, snow blowers and planers for the excavator arm; all of these products were born to be used in canalisation and road maintenance jobs. Simex has gone on to take its place among the European market leaders in this very niche field.

Latterly, Simex has produced rotary cutters for excavator arms. The firm’s eight rotary cutter models can be attached to excavators weighting from 1.5 up to 60tonnes and are suitable for quarry jobs, controlled demolitions, and deep trench works.

Stand: B3.222

%$Linker: