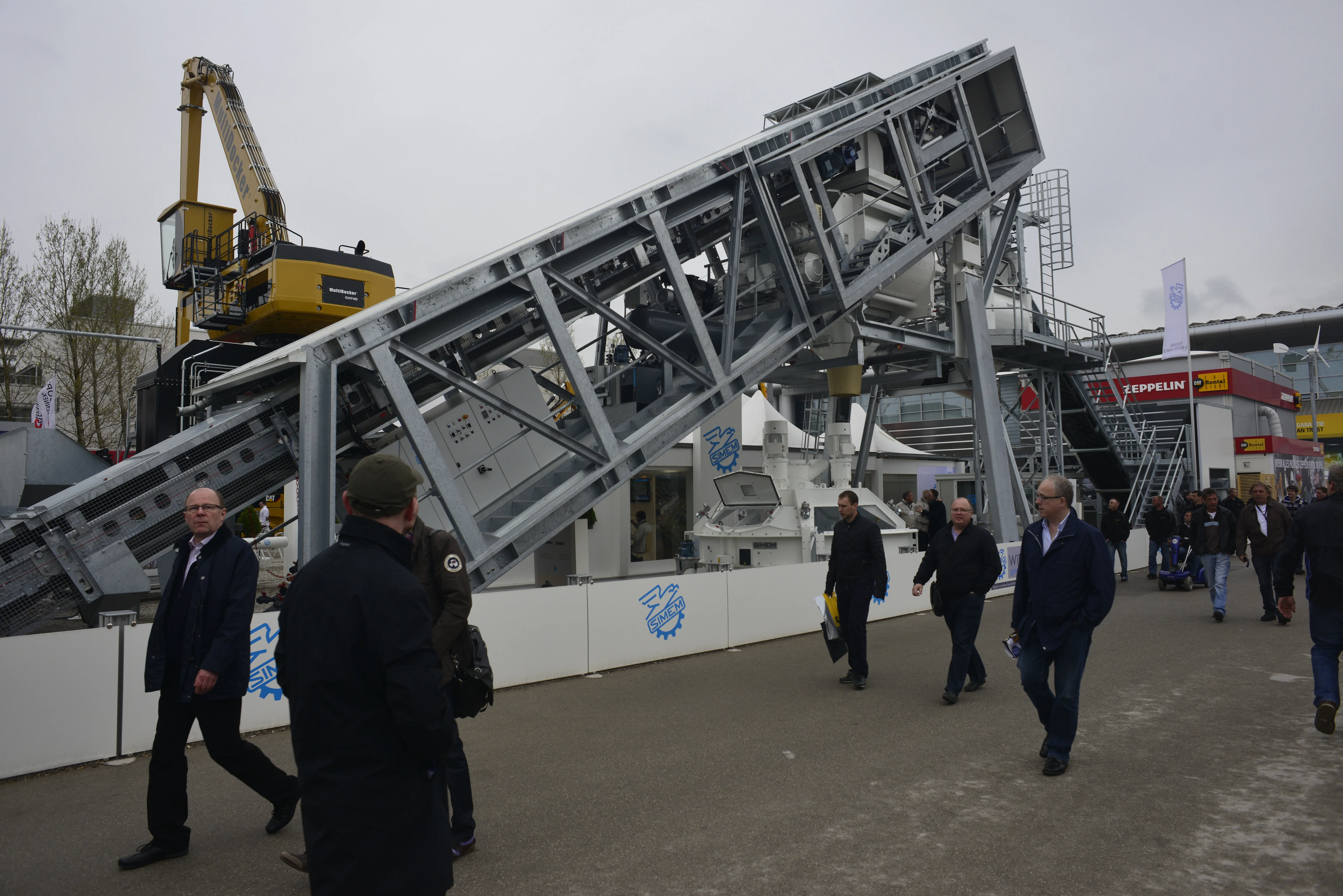

Focal point of Simem’s stand at bauma was an example of its Eagle portable concrete batching plant, which is said to offer top performance at lower cost without compromising the firm’s emphasis on quality. Modular elements with pre-installed pneumatic-electric systems are the key to enabling swift transfer of the Eagle plant from one project to the other. The ‘super-mobile’ MMX range of plant from Simem – said to be the best solution available for faster moving sites such as railways and highways – was also

January 6, 2017

Read time: 1 min

Focal point of 2595 Simem’s stand at 688 Bauma was an example of its Eagle portable concrete batching plant, which is said to offer top performance at lower cost without compromising the firm’s emphasis on quality.

Modular elements with pre-installed pneumatic-electric systems are the key to enabling swift transfer of the Eagle plant from one project to the other.

The ‘super-mobile’ MMX range of plant from Simem – said to be the best solution available for faster moving sites such as railways and highways – was also highlighted at the show.

2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Modular elements with pre-installed pneumatic-electric systems are the key to enabling swift transfer of the Eagle plant from one project to the other.

The ‘super-mobile’ MMX range of plant from Simem – said to be the best solution available for faster moving sites such as railways and highways – was also highlighted at the show.

Stand: F7.709/2

%$Linker:

%$Linker: