Rammer, which has remained a recognised name in hydraulic hammers and attachments although it was withdrawn in 2007, is set to make a return as Sandvik Construction announces a multi-brand strategy. Through the reintroduction of Sandvik-owned Rammer-branded products, the company says it will be able to serve a wider customer base by using differing breaker-focused distribution channels. The Rammer brand was withdrawn when the entire Breakers Lahti product line came under the Sandvik Mining and Construction

January 6, 2017

Read time: 2 mins

RSS5076 Rammer, which has remained a recognised name in hydraulic hammers and attachments although it was withdrawn in 2007, is set to make a return as 2403 Sandvik Construction announces a multi-brand strategy.

Through the reintroduction of Sandvik-owned Rammer-branded products, the company says it will be able to serve a wider customer base by using differing breaker-focused distribution channels.

The Rammer brand was withdrawn when the entire Breakers Lahti product line came under the Sandvik Mining and Construction umbrella.

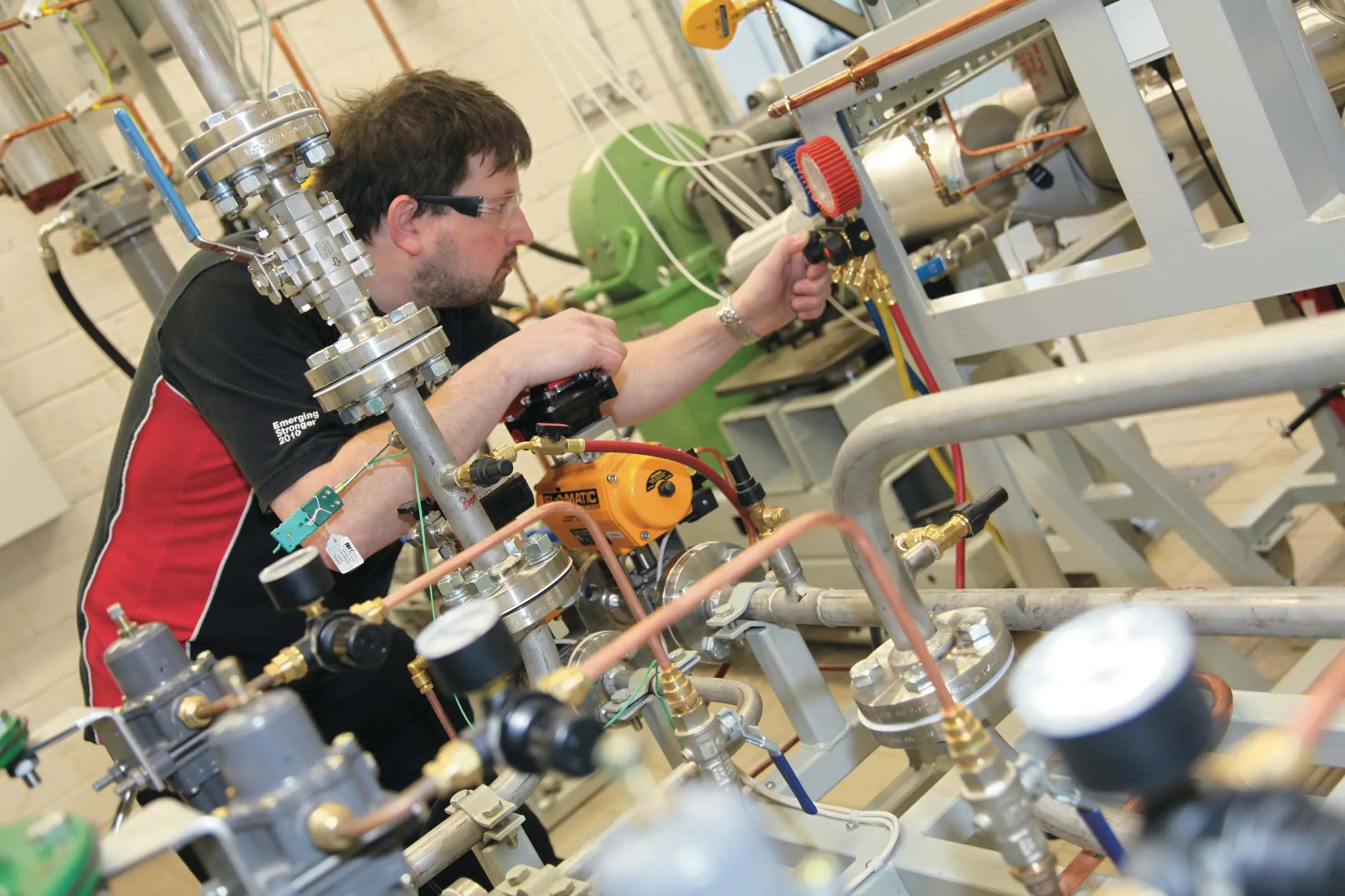

As a key part of the Sandvik brand, the Breakers Lahti facility in Finland “has remained at the forefront of hydraulic breaker innovation, directly benefitting from Sandvik’s experience and know-how”.

In recent years the entire product range has been updated and the company said all developments have benefitted from customer need-based designs and solutions aimed at maximising the uptime of the unit.

“For more than 30 years Rammer enjoyed a level of brand loyalty that was virtually unique in the field of construction equipment. And that popularity has never decreased,” said Ola Ulmala, vice president of breaking.

“Our hydraulic hammer and attachment customers in the construction, demolition and quarrying sectors let us know that they would welcome the return of the Rammer brand and, as a customer-focused company, it is our duty to give those customers what they want.”

Over the years the Rammer brand has developed innovations, many bearing the company name, and these include RAMDATA, the on-board service indicator that provides field information to the user as well as stored data for use by the owner and dealer to ensure optimised use of the unit, and the RAMLUBE automatic lubrication system.

View more stories

View more videos

Through the reintroduction of Sandvik-owned Rammer-branded products, the company says it will be able to serve a wider customer base by using differing breaker-focused distribution channels.

The Rammer brand was withdrawn when the entire Breakers Lahti product line came under the Sandvik Mining and Construction umbrella.

As a key part of the Sandvik brand, the Breakers Lahti facility in Finland “has remained at the forefront of hydraulic breaker innovation, directly benefitting from Sandvik’s experience and know-how”.

In recent years the entire product range has been updated and the company said all developments have benefitted from customer need-based designs and solutions aimed at maximising the uptime of the unit.

“For more than 30 years Rammer enjoyed a level of brand loyalty that was virtually unique in the field of construction equipment. And that popularity has never decreased,” said Ola Ulmala, vice president of breaking.

“Our hydraulic hammer and attachment customers in the construction, demolition and quarrying sectors let us know that they would welcome the return of the Rammer brand and, as a customer-focused company, it is our duty to give those customers what they want.”

Over the years the Rammer brand has developed innovations, many bearing the company name, and these include RAMDATA, the on-board service indicator that provides field information to the user as well as stored data for use by the owner and dealer to ensure optimised use of the unit, and the RAMLUBE automatic lubrication system.

Another development, RAMONA (Remote Monitoring Analyser) utilises advanced electronics within the hammer hydraulic system in order to deliver up-to-the-minute condition and performance data to the operator, thereby identifying abnormalities in operating conditions and pre-empting potential failures before they occur.

www.sandvik.comHall: 3 Stand: B085

RSSView more stories

View more videos