Ramtec’s search for a new French dealer for its Robi product range has come to a successful Finnish at INTERMAT. The Lahti-based demolition and recycling equipment specialists put pen to paper on the partnership with Escomel on Tuesday. “It’s a very important move,” said company sales and product manager Benjami Pitkäsalo. “They have a good sales network and we are looking forward to getting new business.”

January 6, 2017

Read time: 1 min

The Lahti-based demolition and recycling equipment specialists put pen to paper on the partnership with Escomel on Tuesday.

“It’s a very important move,” said company sales and product manager Benjami Pitkäsalo. “They have a good sales network and we are looking forward to getting new business.”

Ramtec also unveiled its new MM062 1,300kg screening bucket for 10-16tonne excavators.

“It has a new type of jaw, more plate than rib design, which is good for recycling,” said Pitkäsalo. “We recognised that the Western European market, in particular, wanted this.”

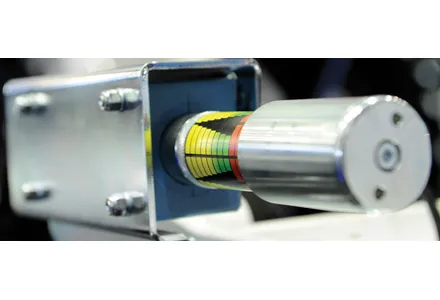

Ramtec is also showcasing its CG20 crusher grapple; a BH30C hydraulic hammer; an MP19 multiprocessor; and its DG15 demolition grapple.

%$Linker: