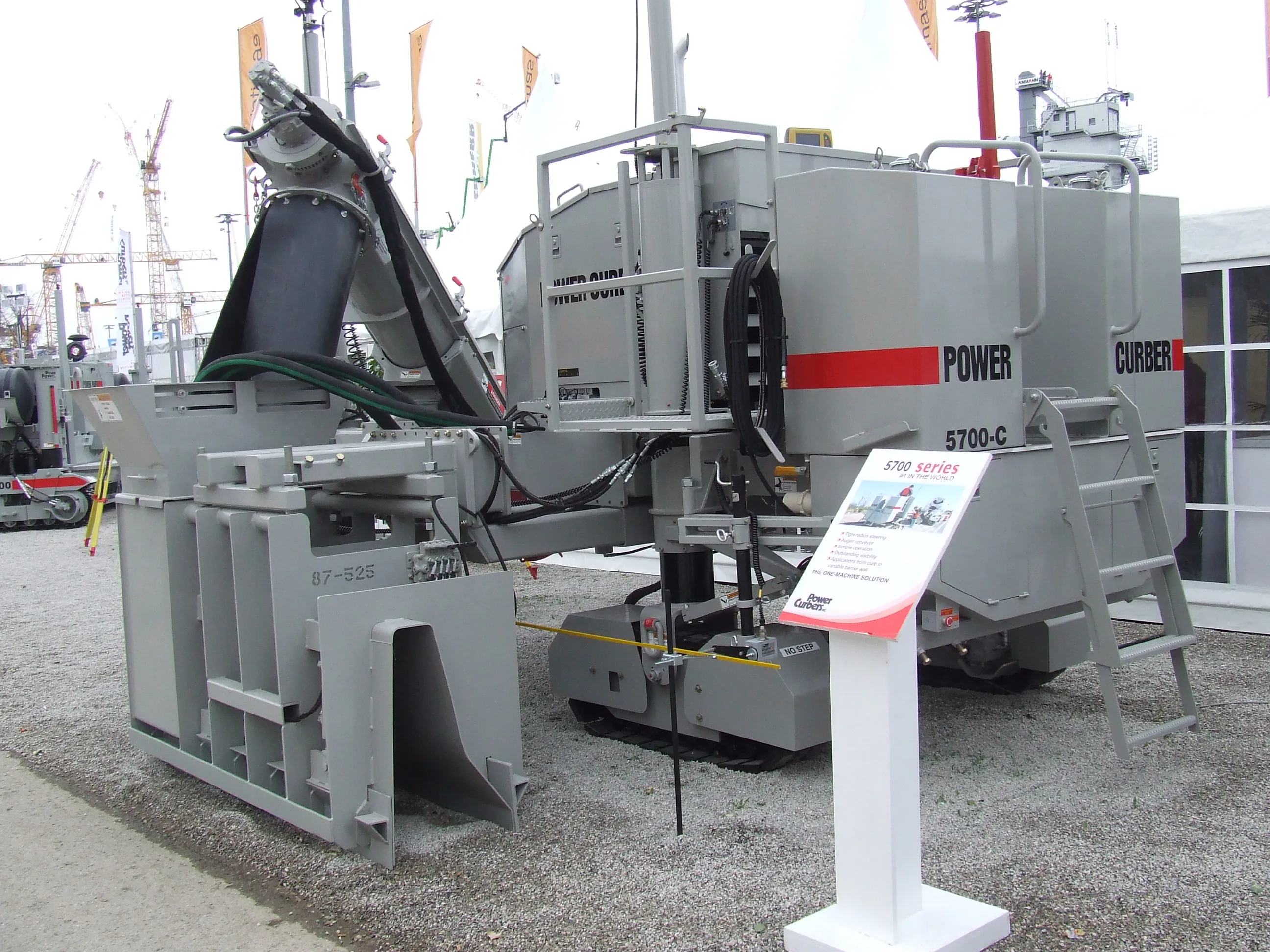

Power Curbers and its sister company Power Pavers exhibited the adaptable 5700-C and SF-1700 models at bauma, slipformers that have been both designed to provide the customer with a high degree of versatility.

April 30, 2013

Read time: 2 mins

The 5700-C seen at the show is a well-proven, compact slipformer able to handle a wide array of barrier wall applications. Meanwhile the SF-1700 from

This versatility is a focus for Power Curbers and also for the Power Pavers range. Dyke Messinger, president and CEO of Power Curbers said, “The customer today wants a machine that can do multiple applications, not just kerb or not just barrier. They want a machine that can pave. Our multi-purpose machine can pave up to 4m wide and it can do barrier up to 2m high.”

Messinger explained that this versatility and adaptability helps ensure that a machine achieves greater utilisation and providing a better return on investment for the owner, with a faster payback time.

The company is also keen to ensure its machines can work with the latest 3D paving controls and introduced the

View more stories