PERI says that with new VARIOKIT system components it is now possible to create a heavy-duty truss girder for bridge construction. A supplement to the VARIOKIT heavy-duty shoring tower launched at bauma 2010, PERI said that during the new truss girder solution’s development it took into account load-bearing capacity of the tower and the challenging requirements of daily construction work. The modular lattice system can be used for spans up to 40m and is said by PERI to have a very high-load bearing capacity

April 18, 2013

Read time: 2 mins

A supplement to the VARIOKIT heavy-duty shoring tower launched at

The modular lattice system can be used for spans up to 40m and is said by PERI to have a very high-load bearing capacity. With the continuously adjustable telescopic support frame, PERI says all spans can be realised with centimetre accuracy. Furthermore, the calotte bearing allows easy adaption to the longitudinal and lateral inclinations of the superstructure. The heavy-duty truss girder can be quickly assembled by fitting pins.

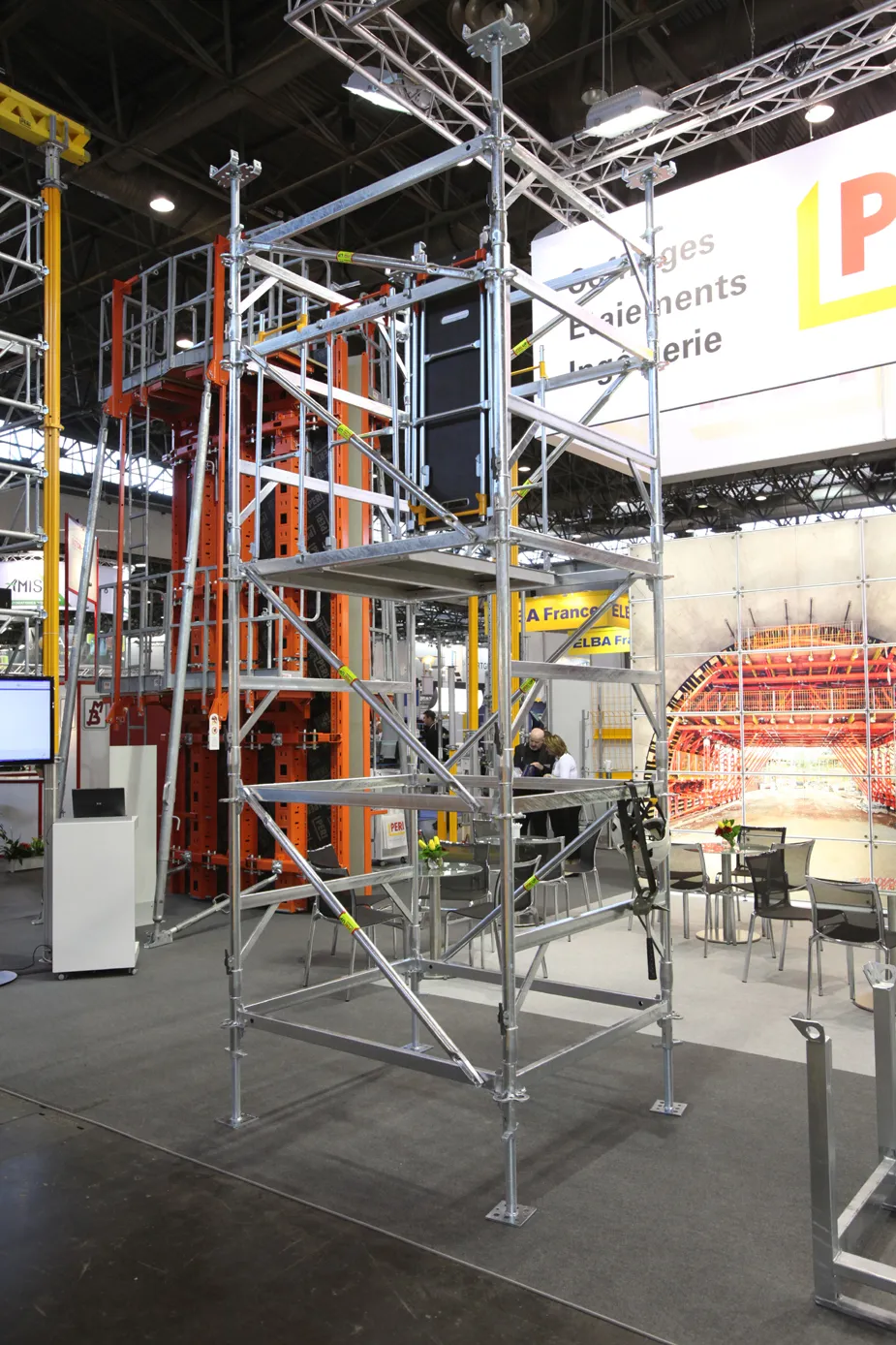

PERI claims the compatibility with the VARIOKIT heavy-duty shoring tower through the Main Beam VRB provides ideal solutions in the heavy-duty shoring sector. Meanwhile, the optional PERI UP scaffolding in the bottom section provides, says the company, totally safe working conditions.

“We are going way beyond capacity of existing systems,” said Bernhard Lindner, product management civil engineer at PERI. “We can go up to 3,000kNm as a maximum bending moment. We want to work on spans up to 35 metres as a standard use. We also intend to go up to 40 metres.”

Lindner said Eastern Europe and North America were likely to be strong markets for the new heavy-duty truss girder solution. “We also have some clients from Serbia. They have looked at the solution and said ‘We want to redesign our bridge to make it more suitable for your system’,” he added.

In combination with the VARIOKIT heavy-duty shoring tower, the new VARIOKIT heavy-duty truss girder will be piloted at T4 – a 390m arched bridge being used to close the gap between Paradisia and Tsakona on the 160km A7 motorway in Greece. The bridge is due to be completed in early 2014.

Stand: FGN.N719

%$Linker:

%$Linker: