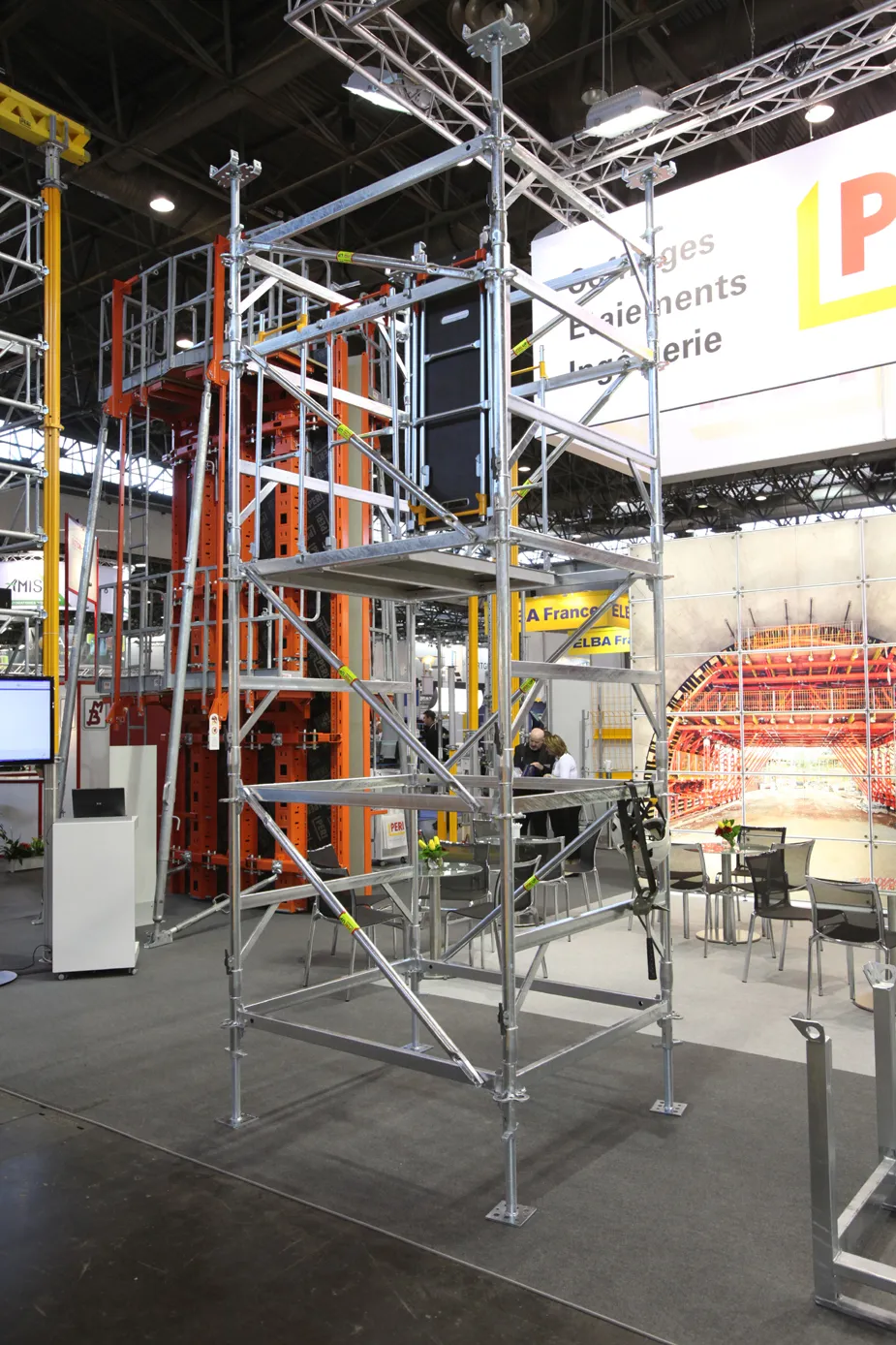

Peri is unveiling its new UP MDS shoring tower to all markets outside France at INTERMAT 2012. The shoring tower is equipped with working platforms hanging from the handrails, providing a high level of security during the erection and dismantling phases, and a significantly reduced exposure to musculoskeletal disorders (MSDs). The working platform sets an automatic working position 1m below the handrail and follows the top of the tower. The system improves productivity by optimising weight (total weight of

February 3, 2012

Read time: 2 mins

The shoring tower is equipped with working platforms hanging from the handrails, providing a high level of security during the erection and dismantling phases, and a significantly reduced exposure to musculoskeletal disorders (MSDs).

The working platform sets an automatic working position 1m below the handrail and follows the top of the tower. The system improves productivity by optimising weight (total weight of the platform is divided by 2, with the heaviest item weighing 16kg) by systemising the erection and the dismantling operations, and by reducing unnecessary movements, bad postures and, as a result, the risk of MSDs.

The optimisation of safety and ergonomics are, according to Peri, what differentiate the UP MDS from all other solutions currently on the market.

Despite the tough global economic climate, Stéphanie Derouet, management assistant at Peri, said that company product sales had gone up since 2010.

“Poland is a booming market and Ukraine is also good, partly because of the need to build new facilities for Euro 2012,” said Derouet.

“We also provide the tunnel formwork for the Panama Canal works. It’s the biggest contact Peri has. Work is being done to make the Canal bigger to allow bigger boats access.”

%$Linker: