New options in the Quard and Quend ranges from Belgium-based specialist in hot-rolled steel plate producer NLMK Clabecq will be introduced at INTERMAT.

January 6, 2017

Read time: 2 mins

New options in the Quard and Quend ranges from Belgium-based specialist in hot-rolled steel plate producer 2323 NLMK Clabecq will be introduced at INTERMAT.

The company is broadening the range of two of its steels used in construction machinery, adding very thin gauges to its Quard abrasion-resistant steel range as well adding to its range of Quend, its new high-yield-strength steel.

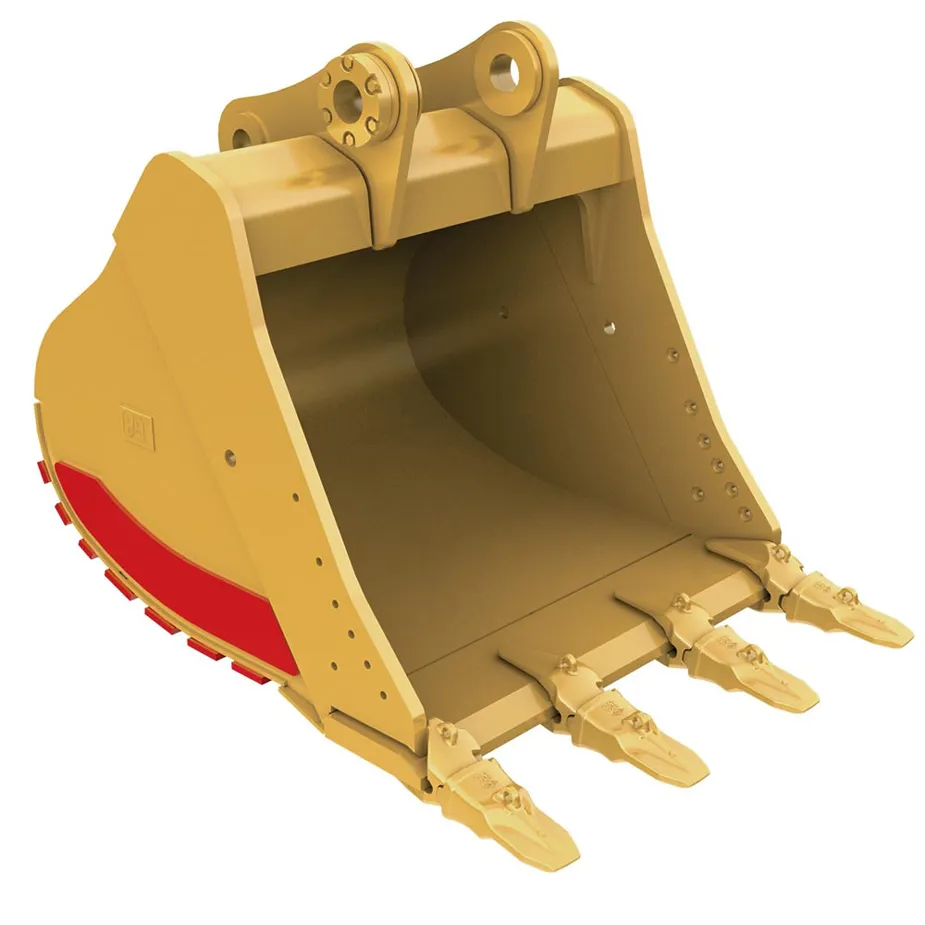

Quard’s thinner plates, which will launched in sizes from 4mm at INTERMAT, are designed to provide a long lifespan on site and to help improve productivity in the workshop thanks to their workability. Use of thinner materials allows producers of construction machinery to reduce the environmental impact. Greater loads can be carried in construction vehicles as the weight of the equipment is kept down when ultra-thin steel is used in its manufacture. The abrasion resistance has been designed to provide a long life in tough situations such as scrap containers, where overall weight is also important.

Quard is joined by Quend, a new high-yield-strength steel aimed at manufacturers of lifting equipment and structures. A typical application would be in mobile crane booms. A trend for longer booms has increased the demand for very high strength steel in thin sections. NLMK Clabecq said that the homogeneity of Quend means that it meets or exceeds the needs of manufacturers in terms of ease of processing in the workshop. Quend is available with a yield strength of 700MPa in thicknesses ranging from 8mm to 25mm. The range will be expanded this year to cover thicknesses from 3mm to 40mm and with a yield strength of up to 1,300MPa.2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The company is broadening the range of two of its steels used in construction machinery, adding very thin gauges to its Quard abrasion-resistant steel range as well adding to its range of Quend, its new high-yield-strength steel.

Quard’s thinner plates, which will launched in sizes from 4mm at INTERMAT, are designed to provide a long lifespan on site and to help improve productivity in the workshop thanks to their workability. Use of thinner materials allows producers of construction machinery to reduce the environmental impact. Greater loads can be carried in construction vehicles as the weight of the equipment is kept down when ultra-thin steel is used in its manufacture. The abrasion resistance has been designed to provide a long life in tough situations such as scrap containers, where overall weight is also important.

Quard is joined by Quend, a new high-yield-strength steel aimed at manufacturers of lifting equipment and structures. A typical application would be in mobile crane booms. A trend for longer booms has increased the demand for very high strength steel in thin sections. NLMK Clabecq said that the homogeneity of Quend means that it meets or exceeds the needs of manufacturers in terms of ease of processing in the workshop. Quend is available with a yield strength of 700MPa in thicknesses ranging from 8mm to 25mm. The range will be expanded this year to cover thicknesses from 3mm to 40mm and with a yield strength of up to 1,300MPa.

%$Linker:

Hall: 5a Stand: H053

%$Linker: