Terex Minerals Processing Systems (MPS) has launched a new modular product line with the MC1000, the first module built in the line, being highlighted at INTERMAT. The line consists of several pre-designed static and semi-static crushing and screening “plug and play” modules, which can be chosen to create the plant required to suit many applications, such as aggregates and mining. “This simple but effective product gives flexibility to our customers to choose ‘ready-to-work’ modules to create the plant they

February 8, 2012

Read time: 2 mins

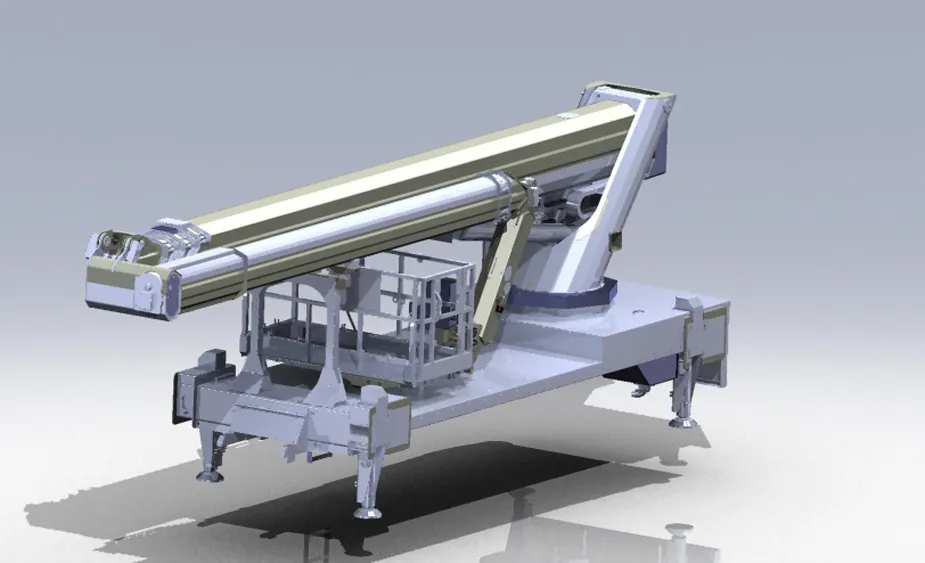

The line consists of several pre-designed static and semi-static crushing and screening “plug and play” modules, which can be chosen to create the plant required to suit many applications such as aggregates and mining.

“This simple but effective product gives flexibility to our customers to choose ‘ready-to-work’ modules to create the plant they need for a variety of applications. It also further enhances the Terex MPS’ product portfolio and will help us to grow in existing markets and enter in to new markets,” says Jason Talbot, global product line director.

The Terex MC1000 series cone module handles an all-in feed for continuous crushing. Its 1,000mm cone has unrestricted feed opening and a full range of configurations for short and long throw.

The company says that the all-roller bearing design improves crushing efficiency. Additional features include hydraulically adjustable closed side setting, easy manganese changes, and a weather protected control panel with user-friendly controls.

“Set up time and ease of operation is aided by the simplicity of the Modular Product range. It is designed to fit and work together interchangeably. The modular product line bolts together on site with little onsite wiring. Designed with logistics in mind, each module, including all its components, can be transported in one container.”

Terex MPS says the cone model has a capacity of 125-220tonnes/hour (70-125tonnes/hour for sand) and the basic crusher weighs 10,000kg. The sand version has a 160kW motor while for other uses it is 185kw.

%$Linker:

Outside: E5 Stand: C002

%$Linker: