Controls Group launched the Automax range of testing machines at bauma 2013.

The Automax Classic is an automatic unit for testing compressive and flexure strength of construction materials; Automax E-Modulus additionally performs tests to determine the elastic modulus and Automax Multitest has an extra channel to allow more sophisticated tests.

Controls has designed its range so that customers can start with a simple machine and upgrade it at a later date. “This way they can start with a basic investment and then expand to a more sophisticated model,” said Controls Group commercial director Flavio Galli.

Controls also used bauma to introduce its paving-focussed division – Pavelab Systems – to the world. “The launch of Pavelab Systems is a clear indication to the end-user that we have the technology and the expertise,” said Galli. “It’s not just the machines, it’s the team of experts behind the machines. If our client has a problem, they call us and ask us for a solution, and with all our knowledge of both EN and ASSHTO standards, we can help them.”

Controls launched Pavelab Systems in October at the same time it unveiled five new asphalt-testing machines. Already it has sold the new machines to clients in China, Mexico, Spain, Holland, Germany, Turkey and Iraq.

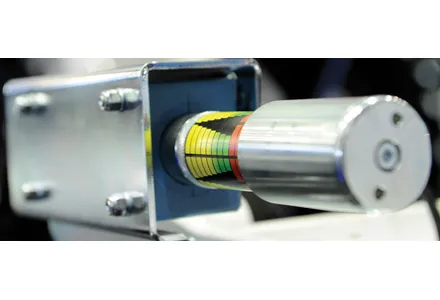

The five new machines are: the Pavelab advanced multi-size slab compactor, for three slab sizes; the Pavelab wet (Hamburg type) and dry double wheel tracker; the Pavelab high-performance ductility meter; the Pavelab automatic closed type bitumen extractor by solvent; and the Pavelab Gyrocomp, gyratory compactor series.

Stand: C1 121

<%$Linker:

<%$Linker: