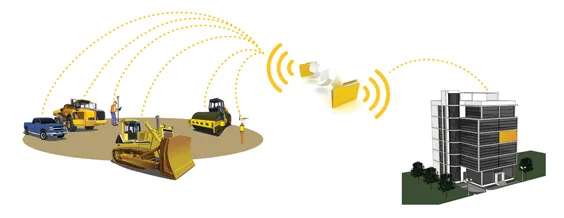

New Holland is exhibiting the 17.9tonne operating weight D150CXLT dozer. It is one of a range of three dozers between 13 and 20tonnes using Tier4i engines fitted with SCR technology to achieve the emissions target and produce a 10.5% fuel saving. It is said to have the quietest cab in the industry (76dB(A)), best-in-class drawbar pull with hydrostatic transmission (311kN) and integration with GPS and laser guidance.

April 19, 2013

Read time: 2 mins

It is said to have the quietest cab in the industry (76dB(A)), best-in-class drawbar pull with hydrostatic transmission (311kN) and integration with GPS and laser guidance.

With 16% more power, the D150C’s engine is more reactive to load changes and its torque growth is higher to avoid big engine rpm drops, which contributes towards a 19% increase in productivity. Control improvements include new electro-hydraulic joystick and the system can integrate with the most GPS and laser-guidance systems.

The three models are available from the factory with a pre-installation kit for

Advanced Track Life (ATL) tracks last twice as long as standard lubricated tracks when working in abrasive conditions and the sprocket has been modified with fewer teeth but with 40% more material under the tooth root area, which triples the wear material between the teeth.

The undercarriage covers have been designed with a 49° angle to improve the self-cleaning effect when working in muddy conditions.

Stand: 5B 307

View more videosView more stories