The new Terex Finlay 863 is a highly versatile and adaptable machine engineered and built to operate in sites where space is at a premium. Designed specifically for quarrying, mining, construction and demolition debris, topsoil, recycling, sand, gravel, coal and aggregate applications, the 863 features a 2755mm x 1200mm top deck and a 2755mm x 1200mm bottom deck. The screen box angle can be adjusted hydraulically between 14 and -18 degrees.

January 6, 2017

Read time: 2 mins

The new 3501 Terex Finlay 863 is a highly versatile and adaptable machine engineered and built to operate in sites where space is at a premium.

Designed specifically for quarrying, mining, construction and demolition debris, topsoil, recycling, sand, gravel, coal and aggregate applications, the 863 features a 2755mm x 1200mm top deck and a 2755mm x 1200mm bottom deck. The screen box angle can be adjusted hydraulically between 14 and -18 degrees.

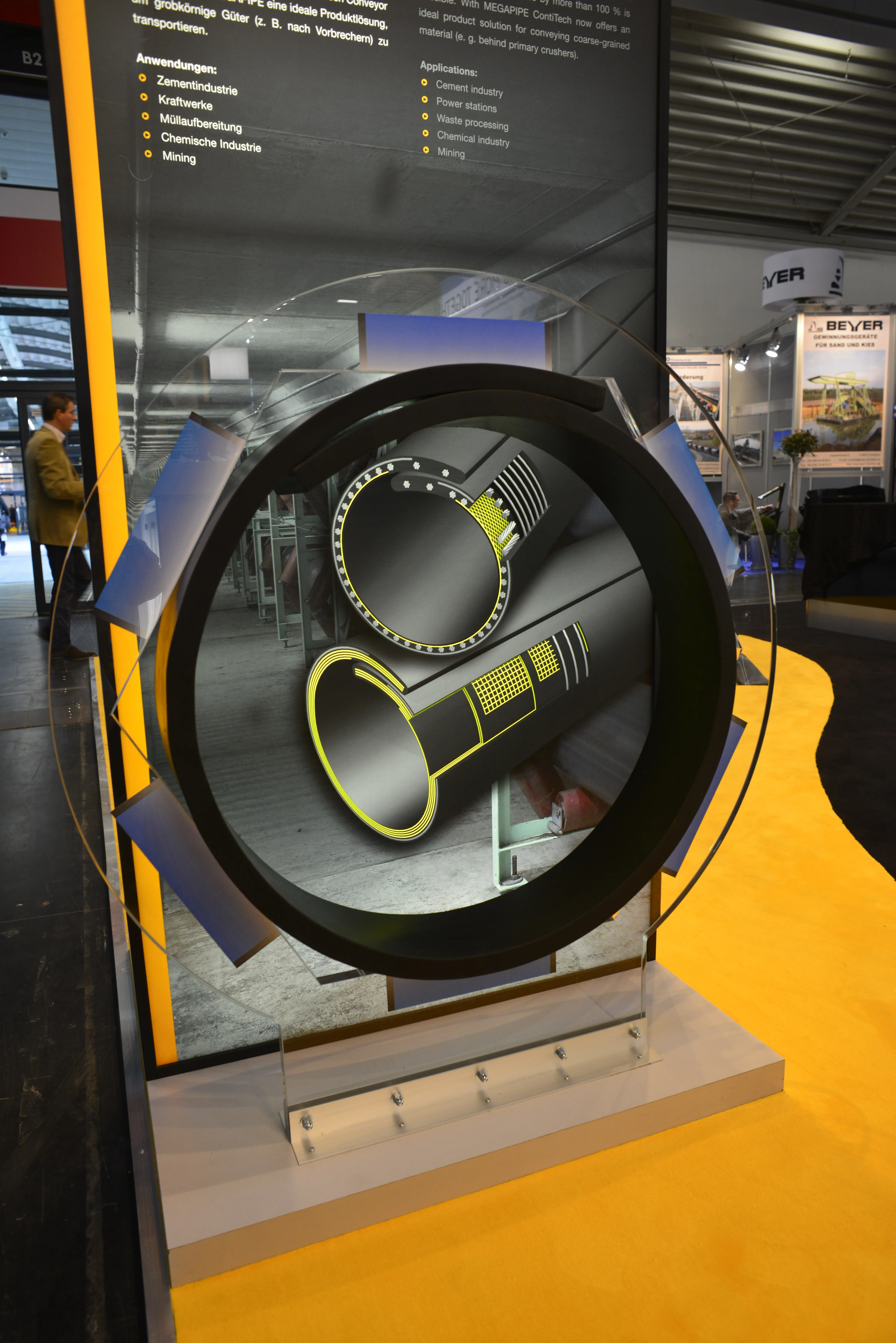

A high performance 1000mm four ply belt feeder, with hydraulic gearbox drive, is fitted to the machine as standard and has proven performance and versatility in demanding and varied working environments. The hopper has a 5m³ capacity as standard.

The machine is equipped with three hydraulically folding discharge conveyors allowing for maximum stockpiling capacity and associated benefits of rapid set up and tear down times.

A Deutz 2011 49kW (66Hp) air-cooled engine is used to power the machine, while the heavy-duty crawler tracks and optional radio remote control unit, make on-site mobility very easy.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

Designed specifically for quarrying, mining, construction and demolition debris, topsoil, recycling, sand, gravel, coal and aggregate applications, the 863 features a 2755mm x 1200mm top deck and a 2755mm x 1200mm bottom deck. The screen box angle can be adjusted hydraulically between 14 and -18 degrees.

A high performance 1000mm four ply belt feeder, with hydraulic gearbox drive, is fitted to the machine as standard and has proven performance and versatility in demanding and varied working environments. The hopper has a 5m³ capacity as standard.

The machine is equipped with three hydraulically folding discharge conveyors allowing for maximum stockpiling capacity and associated benefits of rapid set up and tear down times.

A Deutz 2011 49kW (66Hp) air-cooled engine is used to power the machine, while the heavy-duty crawler tracks and optional radio remote control unit, make on-site mobility very easy.

%$Linker:

Hall: 3 Stand: C141

%$Linker: