HD Hyundai Construction Equipment has opened a new factory for construction machinery in South Korea. The new Smart Plant is located at the firm’s Ulsan Campus. The firm has invested €131 million in this advanced smart factory. The 4,710m2 Campus is a single facility, with automated product flow and advanced quality control, has seen the modernised factory increase production capacity by 56%.

The company says it has been working on the Advancement Project since 2023, expanding and reorganising production lines, constructing a new quality assurance centre and a new receiving building. The firm has also updated its office structure, transforming the plant into a smart facility. Production and logistics have been streamlined under an integrated factory system, while real-time product tracking optimises workflow and efficiency.

Welding robots have been installed in the fabrication facility, with vision sensors on the body welding production line, boosting productivity and quality. Unmanned transport vehicles (AGVs) and AI-based quality inspection systems in the assembly line further increase automation. The time required to complete a machine has decreased by up to 35%.

The Ulsan facility builds medium to large excavators and wheeled loaders and will see production capacity rise by 56%, from 9,600 units/year to up to 15,000 machines/year. This will allow the company to meet the growing demands from customers worldwide.

The site has already delivered its first machines, including a 40tonne Next Generation crawler excavator that was launched at the recent bauma exhibition in Munich. The site has also provided a 125tonne class excavator and 35tonne large wheeled loaders to dealers around the world.

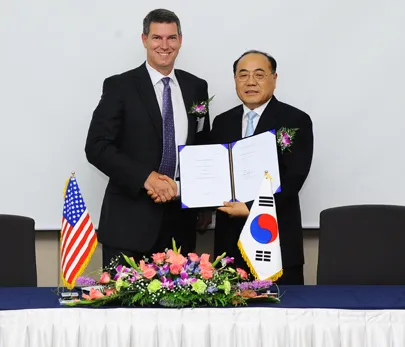

“The Ulsan Campus has been transformed into a smart factory, significantly improving its quality competitiveness,” said CEO Choi Cheol-gon.

“We are dedicated to providing top-tier products, that will lead the construction machinery sector, including our Next Generation models.”