Weighing in at 42-43.3tonnes depending on specification, the new Doosan DX420LC-3 excavator is Stage IIIB/Tier 4 Interim compliant and offers significant benefits over the model it replaces. Improvements include an increase in power, boosting overall productivity and the machine can be used in heavy-duty applications such as earthmoving, demolition and quarrying.

January 28, 2013

Read time: 2 mins

Weighing in at 42-43.3tonnes depending on specification, the new Doosan DX420LC-3 excavator is Stage IIIB/Tier 4 Interim compliant and offers significant benefits over the model it replaces. Improvements include an increase in power, boosting overall productivity and the machine can be used in heavy-duty applications such as earthmoving, demolition and quarrying.

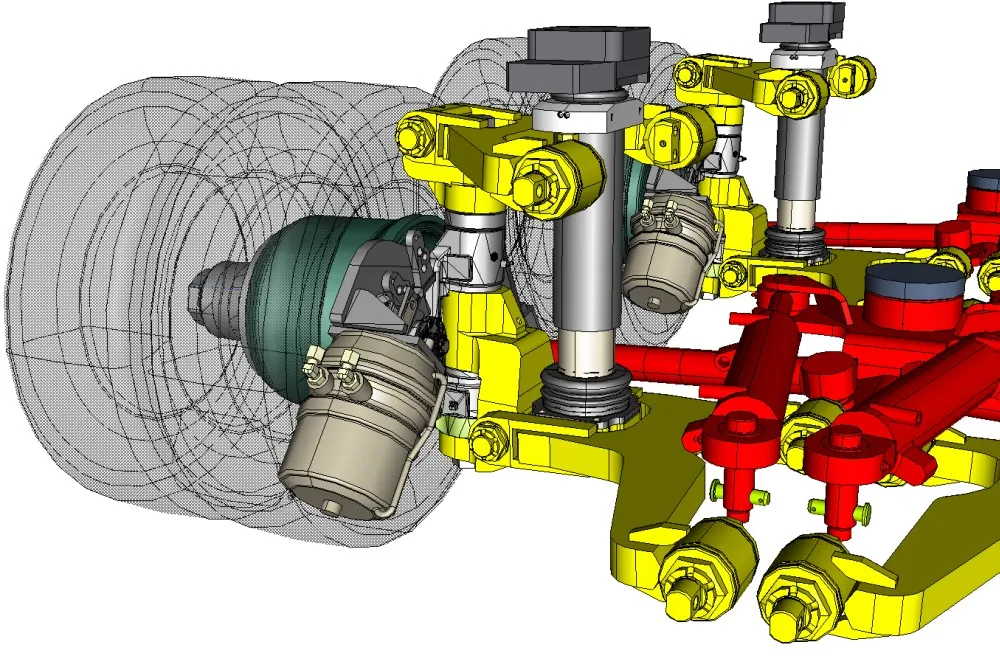

Power comes from an Isuzu AL-6UZ1X diesel engine that features exhaust gas recirculation (EGR) and diesel particulate filter (DPF) after-treatment and delivers 19% more power at 270kW and a 6% increase in torque over the engine in the previous machine from the firm in this size class. A new travel device in the DX420LC-3 excavator contributes to an increase in drawbar pull by 10%, a 5% increase in swing torque and a 10% increase in the travel speed. Improved hydraulic pumps and valves have increased main pump flow by 6%, providing a combination of higher overall pressures and hydraulic flow for increased comfort, travelling performance, smoothness, power and improved attachment work.

Increased operator comfort is claimed for the ROPS and OPG certified cab, which ash 6% more space and features a high quality colour screen on its control console. All functions can be controlled both from the instrument panel. As a standard feature, the operator has access to a new attachment select and setting function, with multiple recordable preset values. Lighting capability has been increased by 100% to facilitate working at night while a side camera is available as an option.

The machine has been beefed up to further boost longevity, with the extra steel increasing overall weight by 1tonne and this also includes a counterweight that weighs 8.2tonnes instead of the previous 8tonnes, maximising stability. A heavy-duty undercarriage is fitted and the service life of the machine has been extended.

Options including a narrow 3m wide undercarriage and a two-mode floating boom system, as well as dual pump flow for high flow attachments, a 6.7m long heavy-duty boom and a 3.25m heavy-duty arm.

2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Power comes from an Isuzu AL-6UZ1X diesel engine that features exhaust gas recirculation (EGR) and diesel particulate filter (DPF) after-treatment and delivers 19% more power at 270kW and a 6% increase in torque over the engine in the previous machine from the firm in this size class. A new travel device in the DX420LC-3 excavator contributes to an increase in drawbar pull by 10%, a 5% increase in swing torque and a 10% increase in the travel speed. Improved hydraulic pumps and valves have increased main pump flow by 6%, providing a combination of higher overall pressures and hydraulic flow for increased comfort, travelling performance, smoothness, power and improved attachment work.

Increased operator comfort is claimed for the ROPS and OPG certified cab, which ash 6% more space and features a high quality colour screen on its control console. All functions can be controlled both from the instrument panel. As a standard feature, the operator has access to a new attachment select and setting function, with multiple recordable preset values. Lighting capability has been increased by 100% to facilitate working at night while a side camera is available as an option.

The machine has been beefed up to further boost longevity, with the extra steel increasing overall weight by 1tonne and this also includes a counterweight that weighs 8.2tonnes instead of the previous 8tonnes, maximising stability. A heavy-duty undercarriage is fitted and the service life of the machine has been extended.

Options including a narrow 3m wide undercarriage and a two-mode floating boom system, as well as dual pump flow for high flow attachments, a 6.7m long heavy-duty boom and a 3.25m heavy-duty arm.

%$Linker: