Easy transportation and installation are key benefits of the new

“It’s highly mobile, and you only need one small crane for the erection,” said Martin Van Stek, Sales Manager with Benninghoven. The plant can be loaded on six trailers, which are built to quickly arrive at the next site. “You can travel at normal road speeds,” he said.

Implemented as a group with four feed hoppers and a loading width of 3,300mm, the cold feed system can be loaded with a wheel loader. The unit also features a loading ramp, which is folded away for transport.

The dryer drum and burner are located on a single chassis. Coordination between the dryer drum and burner ensures maximum productivity and efficiency.

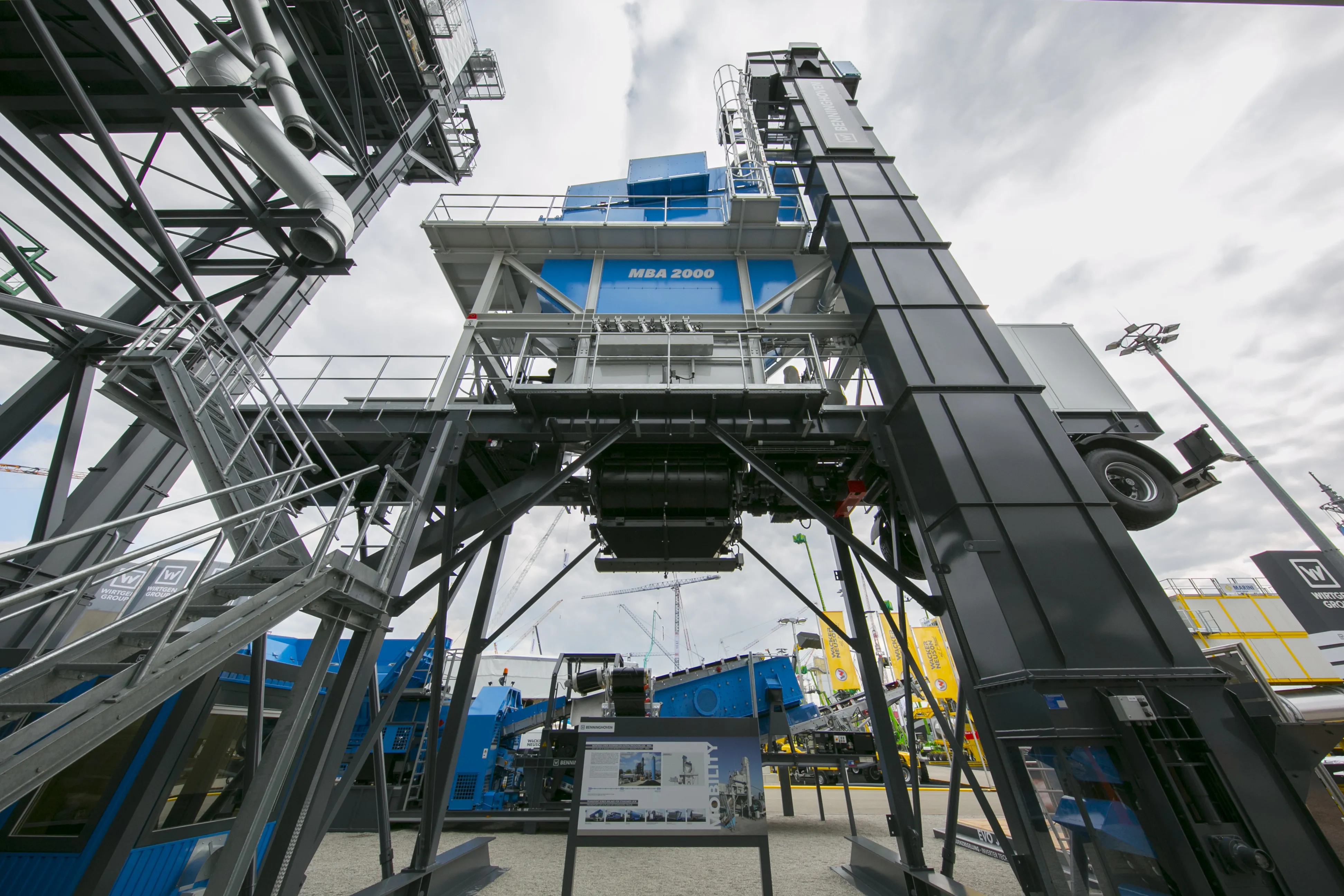

The entire mixing tower is set up in its working position using just one 30tonne crane. The screen, which is also situated on the chassis during transport, is placed on the hot bin section in one stroke. The hot elevator is flange-mounted to the side of the chassis and pivoted. When lifting the mixing tower, the hot elevator automatically arrives at the working position.

A mobile bitumen tank with highly efficient insulation, together with a filling and dosing pump, is supplied as standard.

A mobile command cabin with optimally positioned windows provides a panoramic view of the mixing area. The mixing processes are documented individually, enabling excellent plant statistics and cost calculation.