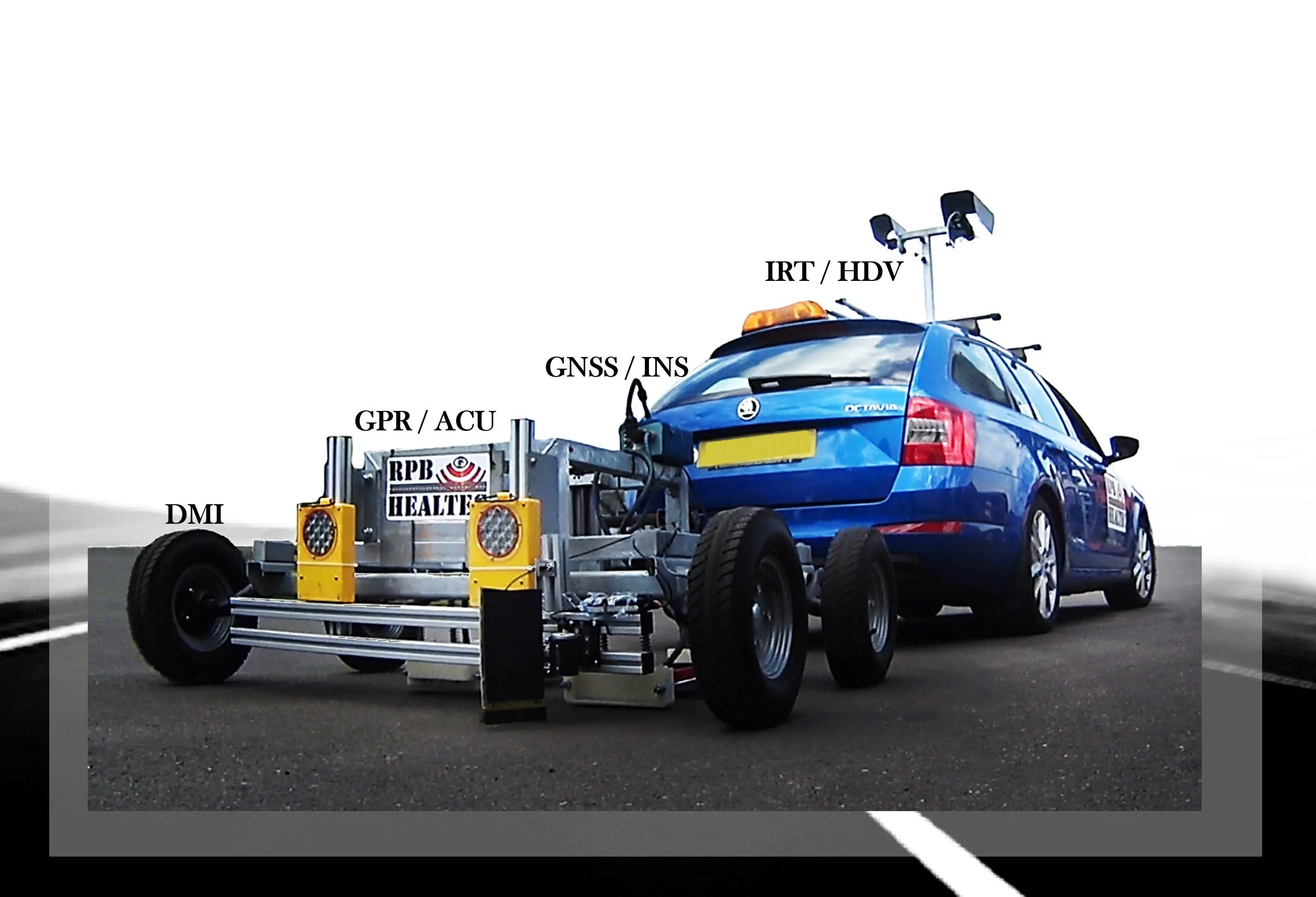

ARRB has signed an important agreement with Radar Portal Systems (RPS), a privately owned company involved in the development of equipment for the measurement of road condition. RPS has a specific focus on ground penetrating radar (GPR) and pavement imaging. The deal will see ARRB and RPS co-operating in research and development, service provision and in the transfer of skills and technology. The primary areas of cooperation will be in the integration of GPR into ARRB’s Hawkeye survey platform to determine

November 5, 2012

Read time: 2 mins

“We have been involved with RPS for some time and are very pleased to be able to work with such an innovative company,” said Garry Warren, general manager of ARRB’s Systems division. “RPS has made some significant advances in the field of road surface and sub-surface imaging and we see our cooperation as a major step in bringing this exciting technology to our customers”.

John Reeves, sales and marketing director of RPS also added “the development of this technology is designed to enhance the ARRB offerings and to bring a greater understanding of pavement dilapidation and design to ARRB customers and partners.”