German firm Herrenknecht has secured the contract to supply the tunnel boring machines (TBMs) for road tunnels at Mumbai Coastal Road Project North.

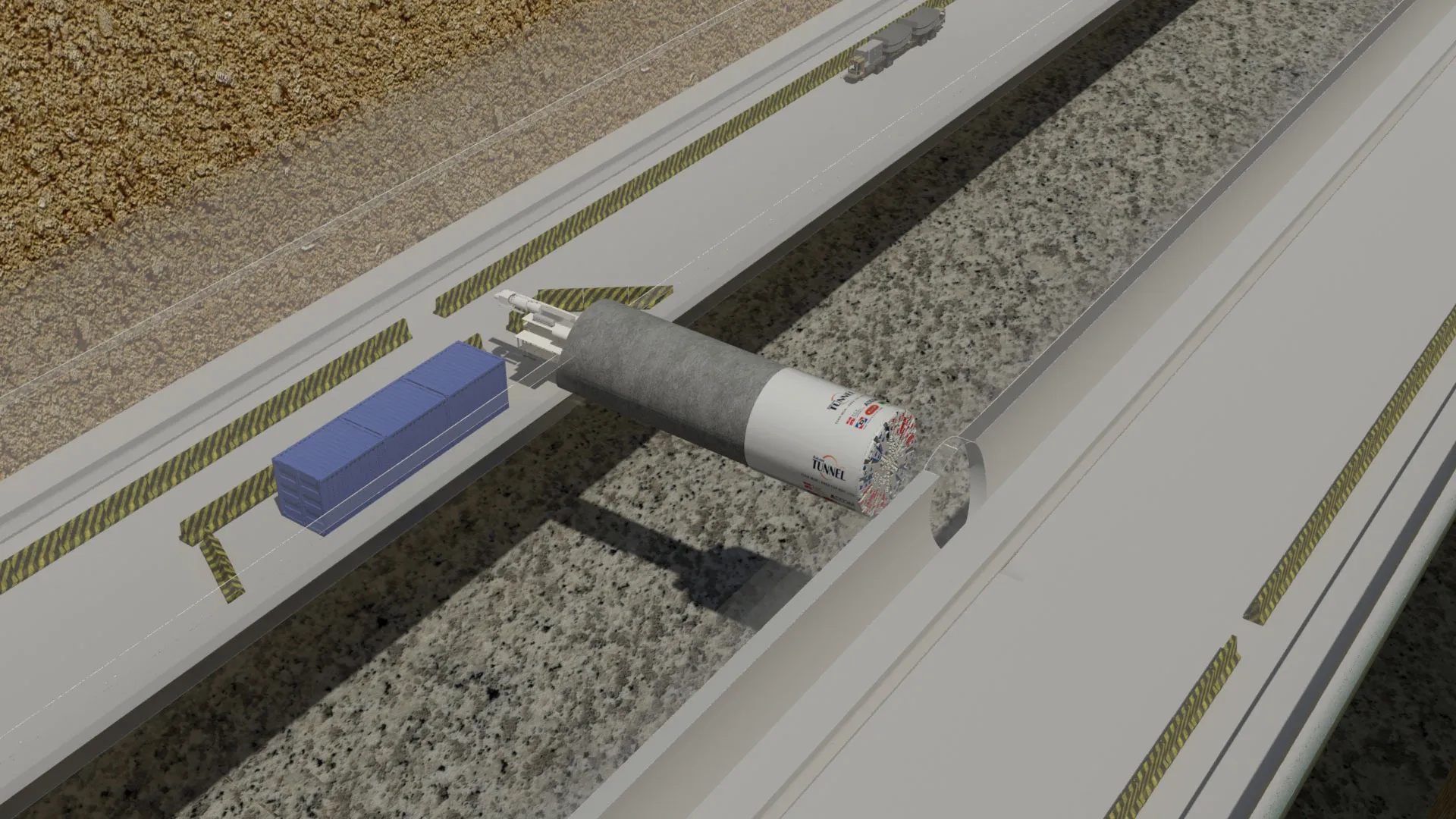

The new TBMs will be used to drive tunnel stretches for the Versova-Dahisar Link Road in Mumbai. The two Mixshields will each feature a diameter of 15.62m, making them the largest tunnel boring machines in India.

The Versova-Dahisar Link Road (VDLR) is the second phase of the Mumbai Coastal Road Project (MRCP), spanning a length of 23km. Packages C & D are the two parallel Underground tunneling packages of VDLR project, each extending 3.1km in length. The planned project will connect the suburbs of Versova and Dahisar along Mumbai's western coastline, easing traffic congestion on major routes such as the Western Express Highway. Underground tunnel sections will play a critical role, particularly in connecting sensitive areas such as the city centre and densely built urban regions. The project owner is Brihanmumbai Municipal Corporation, and the client is Megha Engineering & Infrastructures Ltd (MEIL).

The two powerful Mixshields are optimally designed for the challenging geological conditions of the region: slightly weathered basalt with a uniaxial compressive strength (UCS) of up to 150MPa. The overburden of the tunnels ranges between approximately 13-23m. To ensure safe operations under these conditions, the TBMs are designed for a maximum operating pressure of 5bar. The machines will be manufactured at Herrenknecht's Chennai plant in India, using core components from Schwanau.