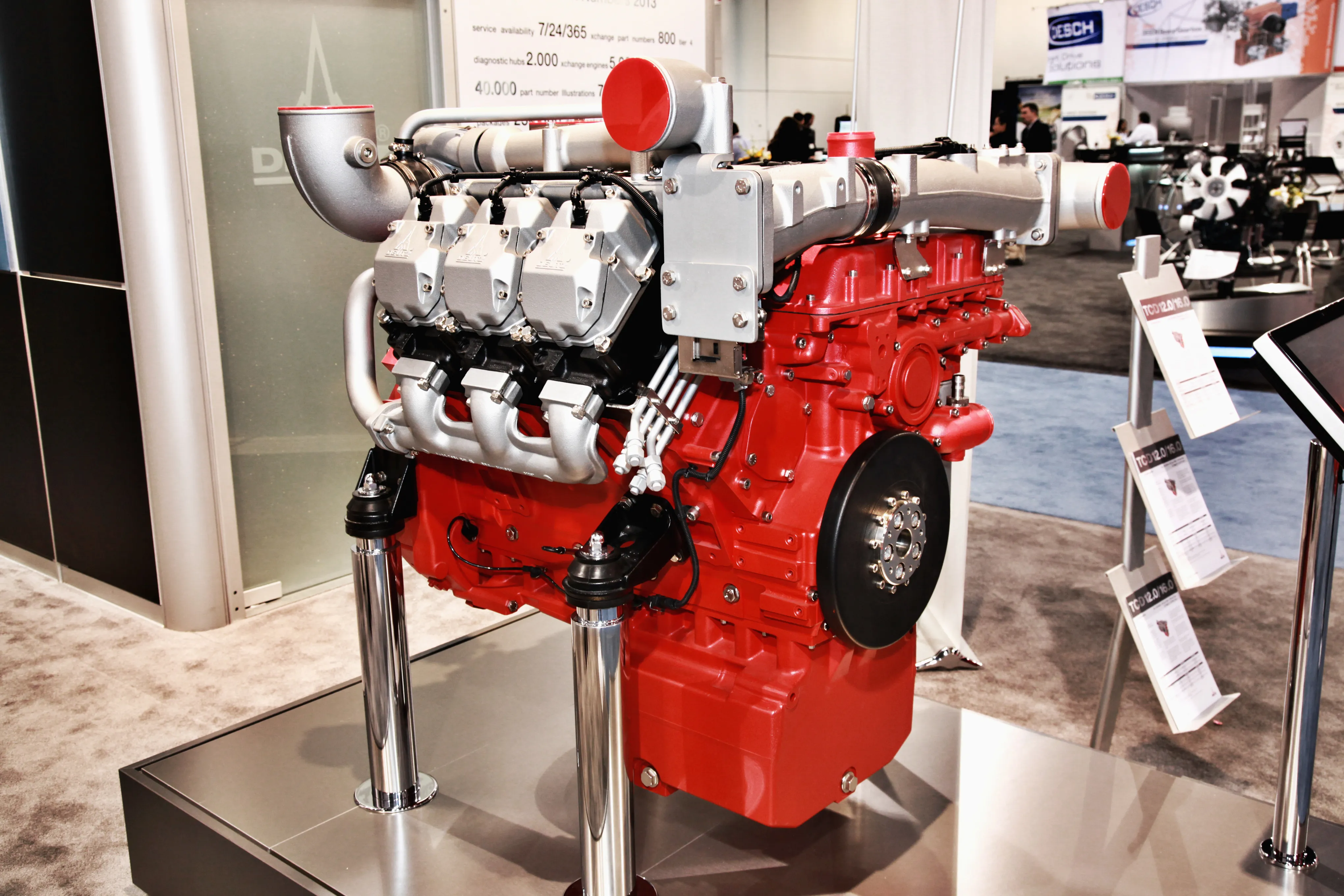

A high-sulphur fuel capability has been announced by MTU for its industrial engines. The move enables OEM’s to adopt the latest MTU engine technology in countries where ultra-low sulphur diesel (ULSD) is not available.

MTU’s sulphur tolerance solution will be available in mid-2014 for Tier 4 Interim 900, 500 and 460 series engines. This will be followed by the company’s complete line up of Tier 4 Final certified engines in the 1000-1500 series in the future.

January 6, 2017

Read time: 1 min

A high-sulphur fuel capability has been announced by 7648 MTU for its industrial engines. The move enables OEM’s to adopt the latest MTU engine technology in countries where ultra-low sulphur diesel (ULSD) is not available.

MTU’s sulphur tolerance solution will be available in mid-2014 for Tier 4 Interim 900, 500 and 460 series engines. This will be followed by the company’s complete line up of Tier 4 Final certified engines in the 1000-1500 series in the future.

The solution involves recalibration of the engine ECU to isolate the after-treatment system. Once disabled, the SCR catalyst does not need to be removed, said the company.

MTU said this new capability should simplify design, ordering and installation processes for OEMs and repower customers around the world.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 80510 0 oLinkExternal www.MTU-Online.com MTU web false /EasySiteWeb/GatewayLink.aspx?alId=80510 false false %>

MTU’s sulphur tolerance solution will be available in mid-2014 for Tier 4 Interim 900, 500 and 460 series engines. This will be followed by the company’s complete line up of Tier 4 Final certified engines in the 1000-1500 series in the future.

The solution involves recalibration of the engine ECU to isolate the after-treatment system. Once disabled, the SCR catalyst does not need to be removed, said the company.

MTU said this new capability should simplify design, ordering and installation processes for OEMs and repower customers around the world.

%$Linker: