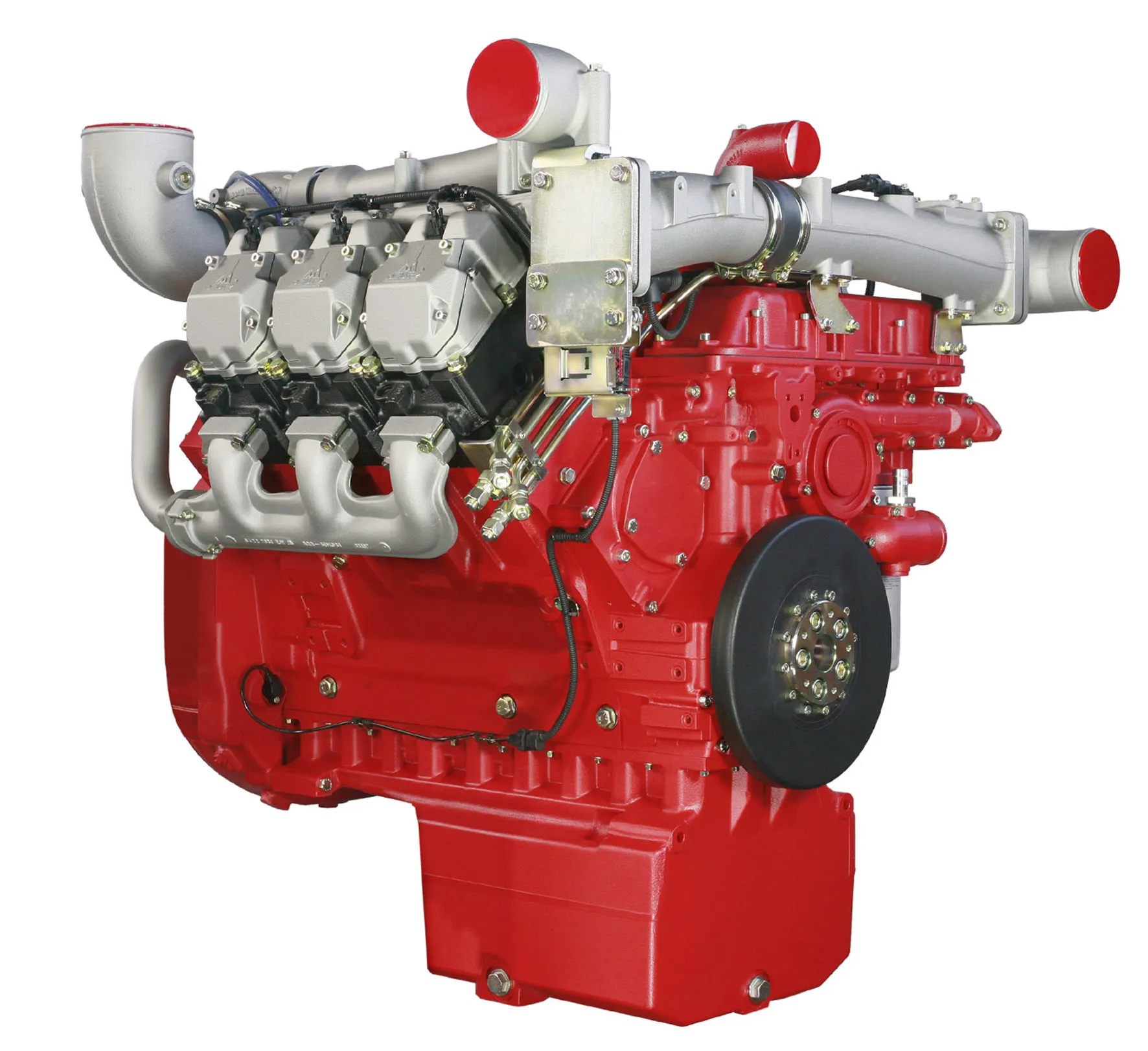

Torgnum Group used bauma 2013 to reveal its new MTU 1600 Series engine platform, developed specifically for off-highway use, that meets EPA Tier 4 Final emissions requirements. In 17.5litre capacity V10 format and 21litre V12, the two new diesel engines span a power range from 567kW-730kW, and provide peak torque figures of 3,500Nm and 4,200Nm respectively. “These two new engine formats slot into our range between the 1500 Series and the 2000 Series engine ranges,” said Mirko Gutemann, Tognum Group marketin

April 17, 2013

Read time: 2 mins

In 17.5litre capacity V10 format and 21litre V12, the two new diesel engines span a power range from 567kW-730kW, and provide peak torque figures of 3,500Nm and 4,200Nm respectively.

“These two new engine formats slot into our range between the 1500 Series and the 2000 Series engine ranges,” said Mirko Gutemann, Tognum Group marketing manager. “They give OEMs more choice for a dedicated off-highway engine that can perform in a variety of applications, including use in haul trucks, mining machinery, wheeled loaders and excavators.”

Using series turbocharging, high pressure common rail electronic fuel injection and cooled EGR, Tognum Group claimed it has achieved a specific fuel consumption figure for the V10 and V12 MTU 1600 Series engine platforms of less than 200g/kW/hour at peak torque and less than 210g/kW/hour at rated speed.

Stand: A4.211/310

%$Linker: