Two new halls - making 18 in total - and an improved site design have made the show even more clear, according to Klaus Dittrich, chief executive of the organiser

The show for construction machinery, accessories and vehicles as well as building material and mining machines, will take place from April 8-14. With the two new halls that together cover 20,000² bauma will provide space for more exhibitors than in 2016 when 3,425 took part.

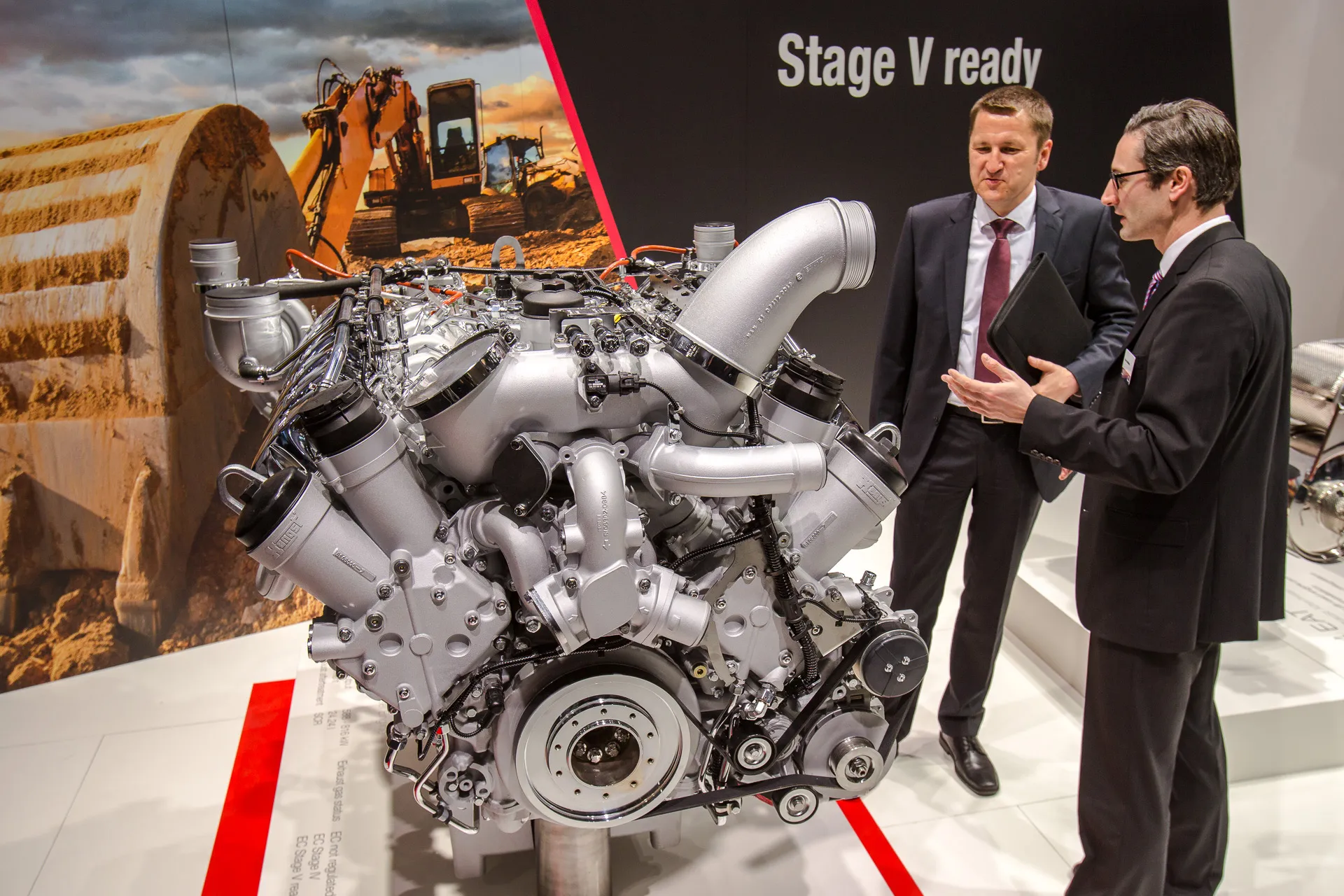

The most important changes at a glance: the largest sector construction machines and attachments is expanded from four to five halls as well as by an additional area outdoors, directly adjacent to the hall complex. The components sector now also has five instead of four halls.

Back again is the special THINK BIG! exhibit that highlights career opportunities for students in the construction and building material machine industries.

During the trade fair, the traffic-calmed part of Paul-Henri-Spaak-Straße will be turned into the pedestrian zone called bauma Boulevard that will host international foods.

More information on the trade show is available at %$Linker: