Three-dimensional technology is playing an increasingly important role on construction sites around the world but there are still projects for which there is no 3D data and the use of a 2D system makes more sense for machine control. With the new 3D-matic, MOBA offers a precise and flexible 3D levelling system for graders, dozers and blades that can also be used as a 2D system if necessary. MOBA 3D-matic increases efficiency in machine use and contributes to fast and precise project execution. The compact t

April 15, 2013

Read time: 2 mins

Three-dimensional technology is playing an increasingly important role on construction sites around the world but there are still projects for which there is no 3D data and the use of a 2D system makes more sense for machine control.

With the new 3D-matic,1228 MOBA offers a precise and flexible 3D levelling system for graders, dozers and blades that can also be used as a 2D system if necessary.

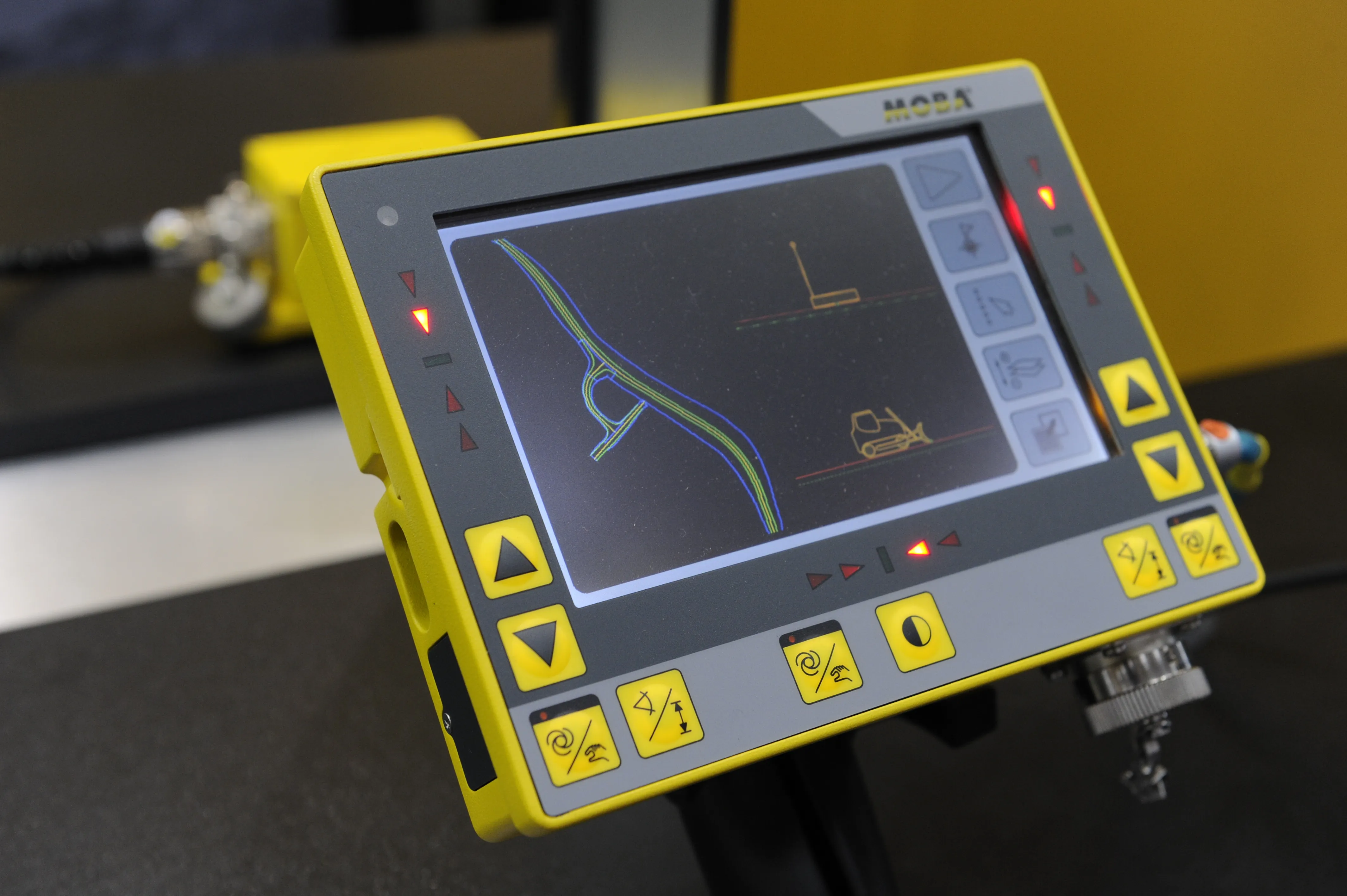

MOBA 3D-matic increases efficiency in machine use and contributes to fast and precise project execution. The compact two-in-one controller combines 2D and 3D computers in a single housing, so depending on the project, the operator can work with 3D or 2D.

The 3D planning data is made available to the system via a data carrier. The position of the machine is ascertained with the GNSS sensor or, alternatively, a total station. The controller compares the machine position with design data and calculates the deviations with any corrections for these deviations performed quickly and precisely in the blade controller. MOBA 3D-matic features a simple and straightforward menu navigation system in a clearly arranged touch-screen display. The rugged components are ideally suited for use on construction sites and can withstand environmental factors such as heat, cold, dust or moisture.

The modular structure of the MOBA systems makes possible problem-free upgrading of all MOBA 2D levelling systems to the 3D system.2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

With the new 3D-matic,

MOBA 3D-matic increases efficiency in machine use and contributes to fast and precise project execution. The compact two-in-one controller combines 2D and 3D computers in a single housing, so depending on the project, the operator can work with 3D or 2D.

The 3D planning data is made available to the system via a data carrier. The position of the machine is ascertained with the GNSS sensor or, alternatively, a total station. The controller compares the machine position with design data and calculates the deviations with any corrections for these deviations performed quickly and precisely in the blade controller. MOBA 3D-matic features a simple and straightforward menu navigation system in a clearly arranged touch-screen display. The rugged components are ideally suited for use on construction sites and can withstand environmental factors such as heat, cold, dust or moisture.

The modular structure of the MOBA systems makes possible problem-free upgrading of all MOBA 2D levelling systems to the 3D system.

Stand: A3.227/326

%$Linker: