Rapid International is back at INTERMAT for the first time in 12 years with a focus on its Rapid Planetary Mixer.

Designed and manufactured in Ireland by Rapid International, the mixer provides “innovation, productivity, pioneering, quality to the manufacture of concrete, in particular architectural precast products, construction and environmental industries”, said Jarlath Gilmore, sales and marketing director. There are seven models in the planetary range with output capacities ranging from 0.375m3 to 3m3

April 18, 2012

Read time: 1 min

Designed and manufactured in Ireland by Rapid International, the mixer provides “innovation, productivity, pioneering, quality to the manufacture of concrete, in particular architectural precast products, construction and environmental industries”, said Jarlath Gilmore, sales and marketing director.

There are seven models in the planetary range with output capacities ranging from 0.375m

3

to 3m

3

“With more concrete produced per hour, we are finding Planetary customers increase production and significantly enhance bottom lines,” said Gilmore.

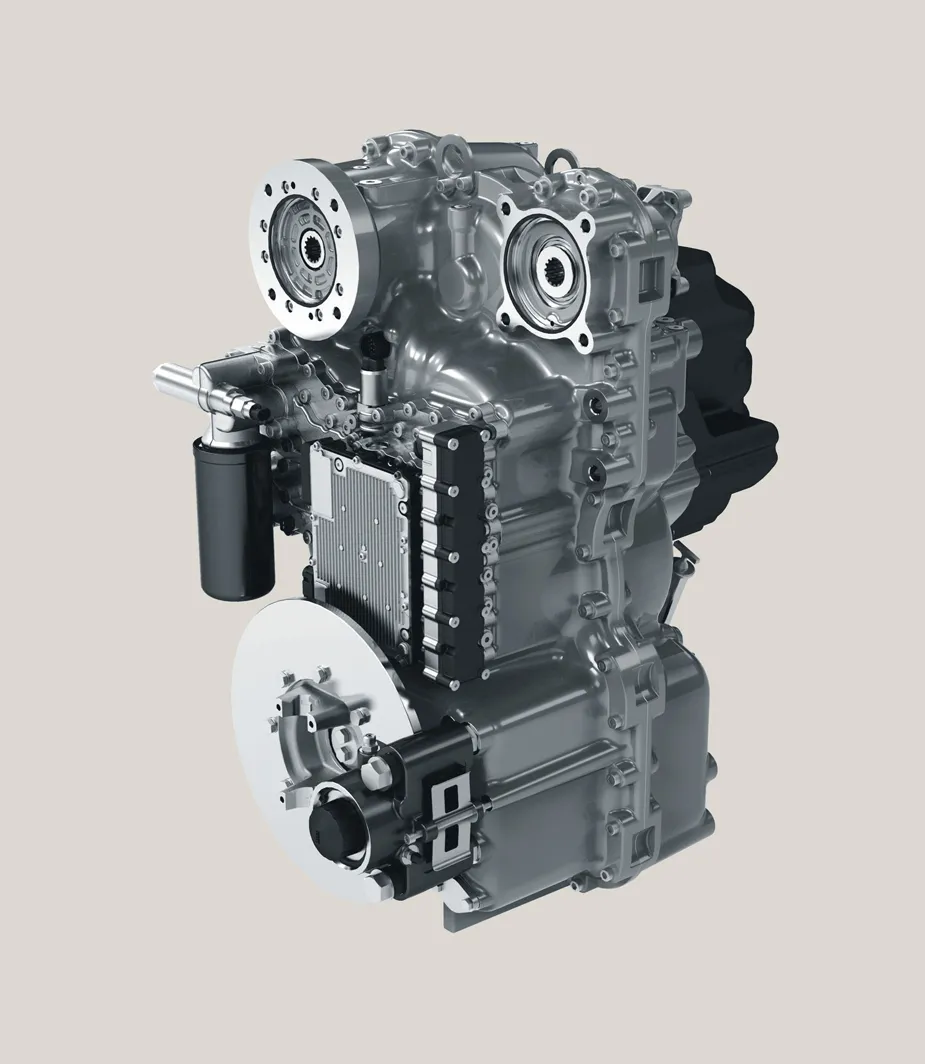

The mixer, motor and gearbox situated on top of the mixer provides ideal access for maintenance and, with standard equipment featuring durable wear sleeves and paddles, the Planetary mixing action consistently produces quality concrete and is ideally suited for mixing semi-dry coloured concrete.

%$Linker: