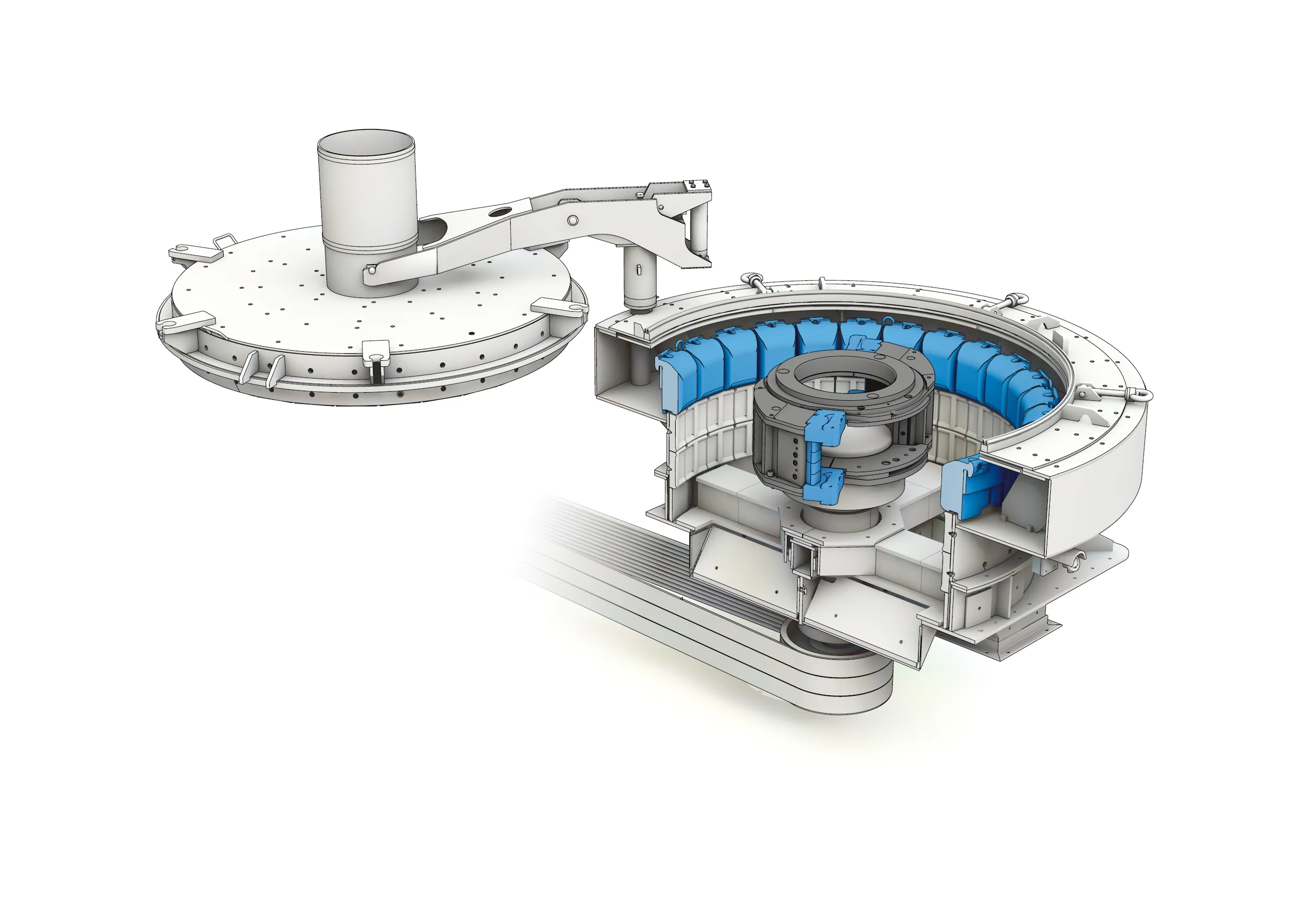

Minyu brought the latest version of a SP cone crusher to INTERMAT. It has been designed to maximise performance by combining an increased speed with a larger crushing chamber, which increases the material capacity and the throughput per hour. The company said that the SP series delivers 30% to 40% more capacity per hour than counterpart spring-type cone crushers. Power transmission from the counter shaft has been increased and better gearing has been introduced, partly thanks to the engineering of the gear

January 6, 2017

Read time: 1 min

RSS5113 Minyu brought the latest version of a SP cone crusher to INTERMAT.

It has been designed to maximise performance by combining an increased speed with a larger crushing chamber, which increases the material capacity and the throughput per hour.

The company said that the SP series delivers 30% to 40% more capacity per hour than counterpart spring-type cone crushers.

Power transmission from the counter shaft has been increased and better gearing has been introduced, partly thanks to the engineering of the gear assembly.

View more stories

View more videos

It has been designed to maximise performance by combining an increased speed with a larger crushing chamber, which increases the material capacity and the throughput per hour.

The company said that the SP series delivers 30% to 40% more capacity per hour than counterpart spring-type cone crushers.

Power transmission from the counter shaft has been increased and better gearing has been introduced, partly thanks to the engineering of the gear assembly.

Hall: 3 Stand: C136

RSSView more stories

View more videos