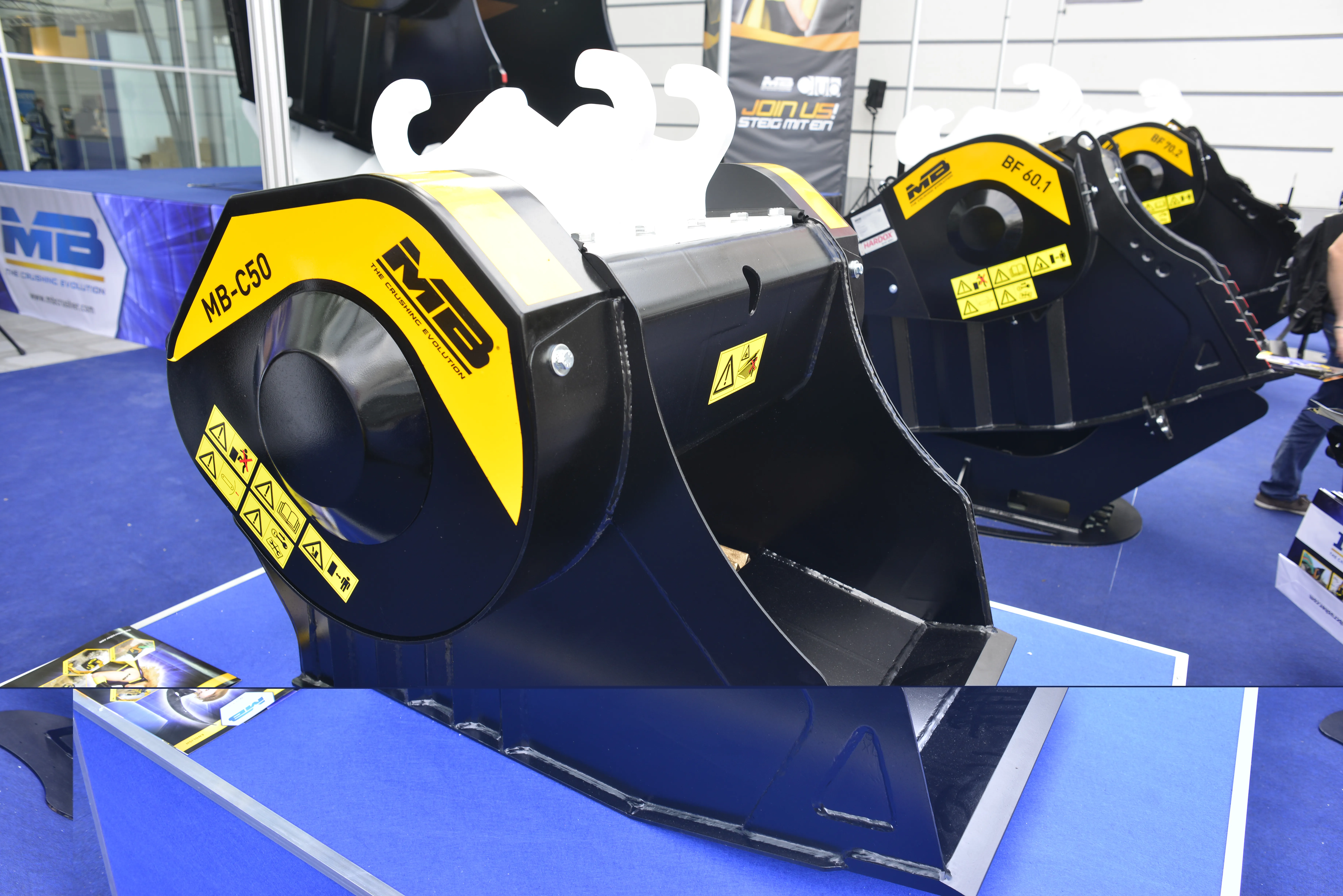

New crushing and screening buckets from attachment specialist MB sees the company moving down the weight range to fulfil customer demand. The new MB-C50 rushing bucket and MB-S10 screening attachment are both designed for excavators in the 4tonne to 8tonne weight range.

April 16, 2013

Read time: 1 min

New crushing and screening buckets from attachment specialist 283 MB sees the company moving down the weight range to fulfil customer demand.

The new MB-C50 rushing bucket and MB-S10 screening attachment are both designed for excavators in the 4tonne to 8tonne weight range.

Throughput on the MB-C50 crusher bucket is put at 5m3/hr and its 0.5m3 bucket has an opening of 550mm by 280mm. Output size is adjustable between 15mm and 70mm. The MB-S10 screen has a 0.6m3 bucket capacity with an 880mm diameter spinning basket that is 560mm deep.

The company has also added the MB-L200 crushing bucket for backhoe loaders between 7tonnes and 10tonnes and skid steer loaders above 4.5tonnes. Maximum throughput is put at 21m3/hr and the output size ranges from 15mm to 50mm.

View more stories

The new MB-C50 rushing bucket and MB-S10 screening attachment are both designed for excavators in the 4tonne to 8tonne weight range.

Throughput on the MB-C50 crusher bucket is put at 5m3/hr and its 0.5m3 bucket has an opening of 550mm by 280mm. Output size is adjustable between 15mm and 70mm. The MB-S10 screen has a 0.6m3 bucket capacity with an 880mm diameter spinning basket that is 560mm deep.

The company has also added the MB-L200 crushing bucket for backhoe loaders between 7tonnes and 10tonnes and skid steer loaders above 4.5tonnes. Maximum throughput is put at 21m3/hr and the output size ranges from 15mm to 50mm.

View more stories