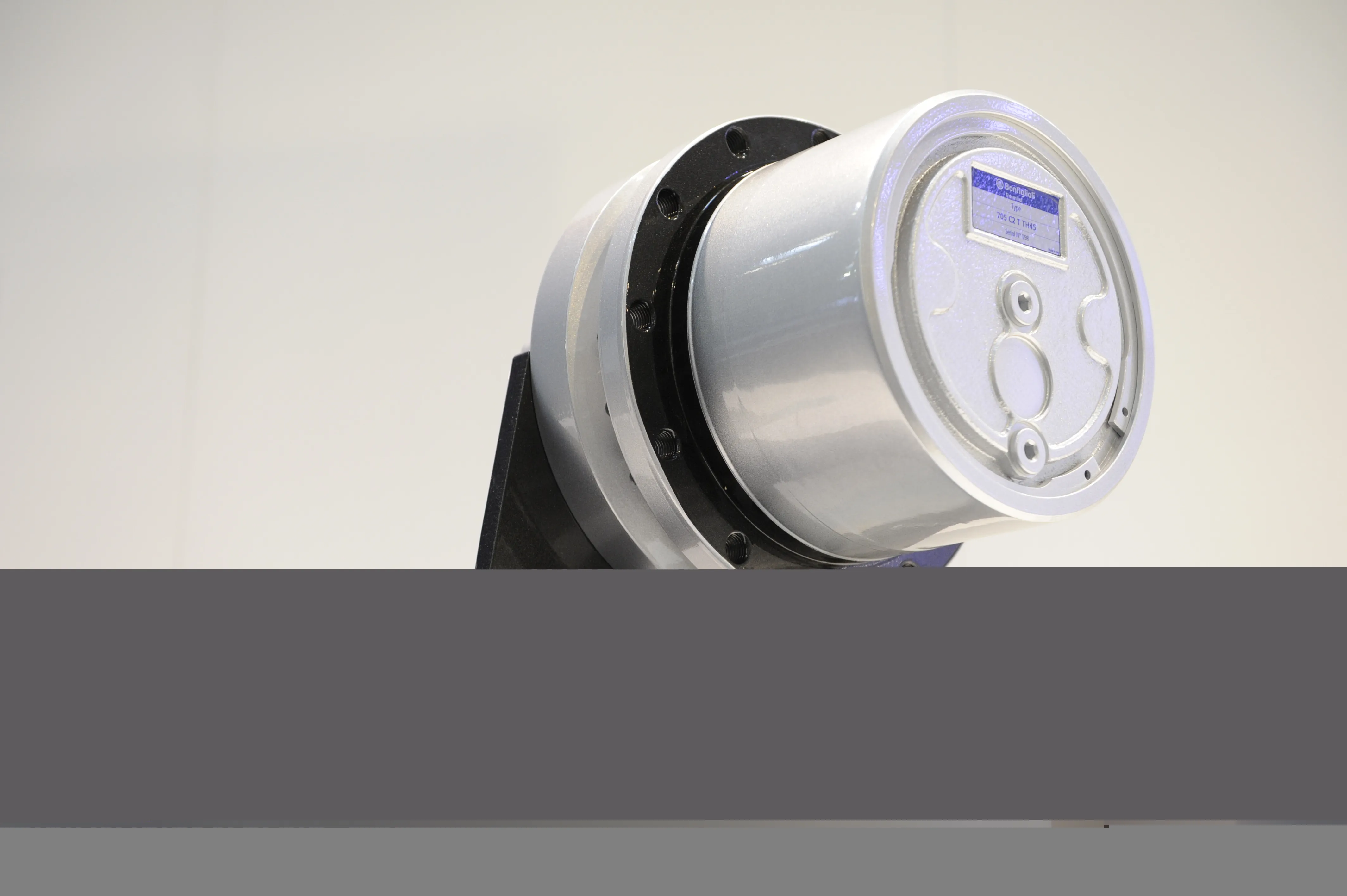

Massenza has redesigned its polymer modified bitumen (PMB) mill to deliver improved efficiencies of up to 40%. The manufacturer has made three changes to the previous model in developing the PMB 490-S.

“Thanks to three new features, the new PMB mill can improve efficiency by up to 40%,” said director Diego Massenza.

The company has changed the configuration of the cutting area, increased the cutting area and modified the inlet for the bitumen polymer. “It needs fewer passages of the bitumen polymer through the mill, which means you improve the production output of the plant,” said Massenza. “And, as a consequence, you shorten the digestion time of the PMB once it is stored in the curing tanks.”

The PMB 490-S will be available in two to three months’ time. “We have already tested it in Italy with a company which needed to upgrade its existing production,” said Massenza. “The results are really very good.”

Massenza has developed a strong customer base in Russia and, with more than 100 Russian visitors expected at its bauma stand, the manufacturer is hoping that its first customer for the new mill will be Russian.

Though the PMB 490-S is on display at bauma, Massenza is keeping the detail of the internal changes under wraps. Massenza was the first company to develop a PMB mill specifically for the bitumen industry and this latest upgrade is a way of keeping ahead of the competition, said Massenza.

Stand: B3.115

<%$Linker: