Environmental issues are now more than ever shaping decisions that governments make when it comes to road building which means contactors have to prove their credentials. For that reason alone sales of the combined polymer and crumb rubber onsite bitumen plant the Italian family business Massenza have been doing well in Europe, said Diego Massenza, who has been in the business for 15 years and is now general manager. The plant was developed by Massenza, a 70-year-old company based in Bologna, around 2010, a

February 24, 2015

Read time: 2 mins

Environmental issues are now more than ever shaping decisions that governments make when it comes to road building which means contactors have to prove their credentials.

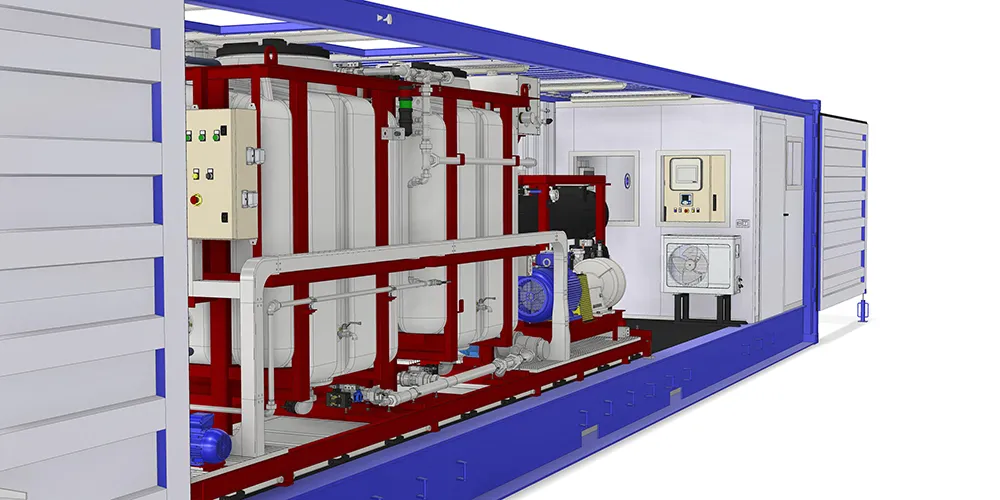

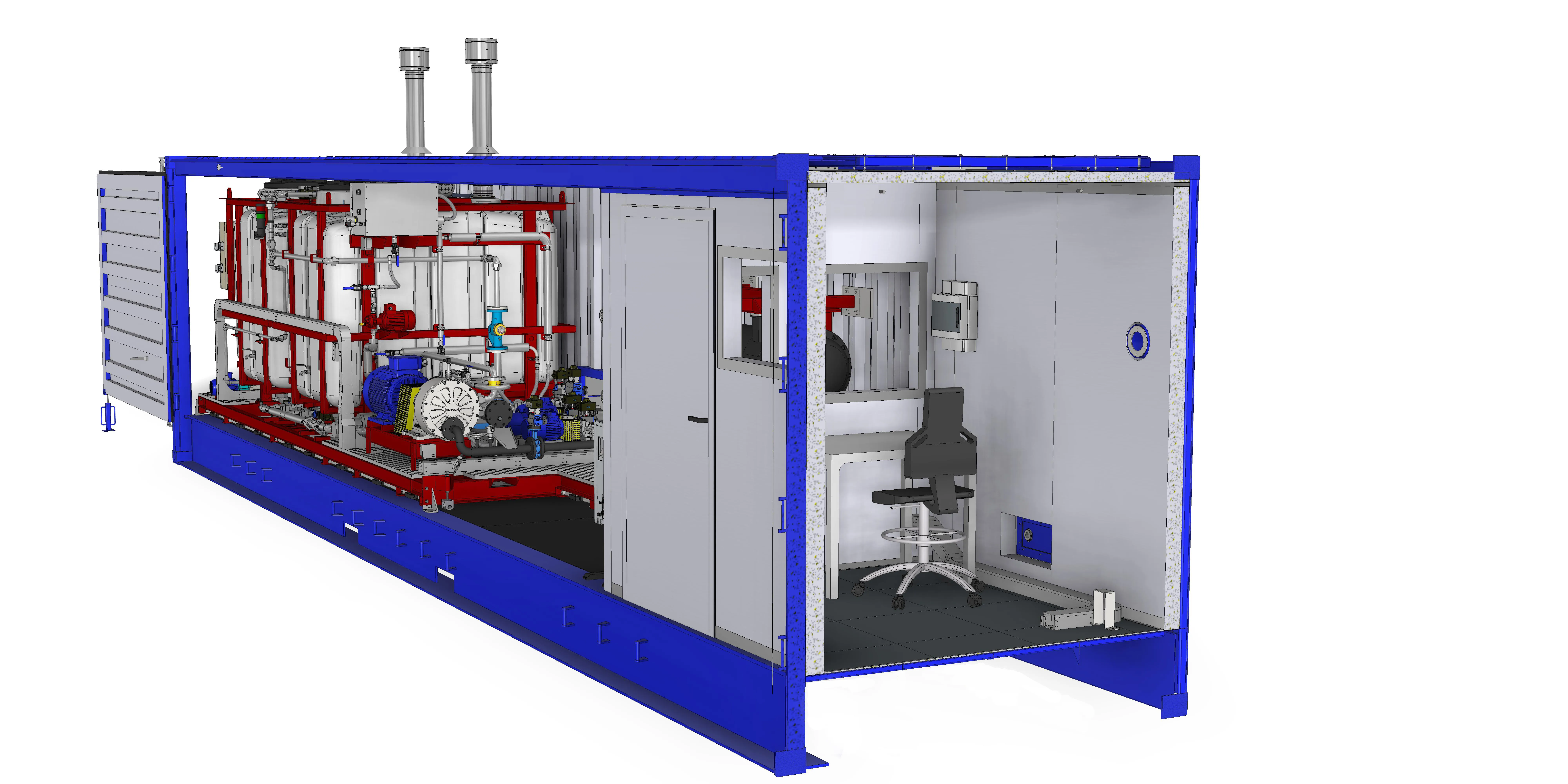

For that reason alone sales of the combined polymer and crumb rubber onsite bitumen plant the Italian family business6805 Massenza have been doing well in Europe, said Diego Massenza, who has been in the business for 15 years and is now general manager.

The plant was developed by Massenza, a 70-year-old company based in Bologna, around 2010, and it appears to have come along at the right time, Massenza told World Highways during a break at the Pavement Preservation and Recycling Summit in Paris.

Many governments are under siege to come up with policies to help the environment and Massenza’s combined plant is a direct user of old tyres in the form of crumb rubber, so it’s a visible solution to an environmental problem, he said.

The Spanish and Greek markets have been increasingly important for the plant, but also the Middle East is coming up fast.

Massenza, who also outlined the plant to delegates during his presentation in the morning Innovation Session at PPRS, noted that the clients are also looking for increasing flexibility. The fact that the plant can easily switch from crumb rubber to polymer means there is a cost saving – only one plant is needed for the two processes. It also is set up on site within a day.

North America, which has some of the most stringent environmental rules and regulations, is still a market not explored be the family business, explained Massenza. The demand may be there but it’s a tough market to crack, he said, because of extensive machine licencing and permits required at all levels of government.

For that reason alone sales of the combined polymer and crumb rubber onsite bitumen plant the Italian family business

The plant was developed by Massenza, a 70-year-old company based in Bologna, around 2010, and it appears to have come along at the right time, Massenza told World Highways during a break at the Pavement Preservation and Recycling Summit in Paris.

Many governments are under siege to come up with policies to help the environment and Massenza’s combined plant is a direct user of old tyres in the form of crumb rubber, so it’s a visible solution to an environmental problem, he said.

The Spanish and Greek markets have been increasingly important for the plant, but also the Middle East is coming up fast.

Massenza, who also outlined the plant to delegates during his presentation in the morning Innovation Session at PPRS, noted that the clients are also looking for increasing flexibility. The fact that the plant can easily switch from crumb rubber to polymer means there is a cost saving – only one plant is needed for the two processes. It also is set up on site within a day.

North America, which has some of the most stringent environmental rules and regulations, is still a market not explored be the family business, explained Massenza. The demand may be there but it’s a tough market to crack, he said, because of extensive machine licencing and permits required at all levels of government.