Major Wire Industries’ innovative Flex-Mat 3 vibrating wire technology for screening will be on show. The Montreal, Canada-based company, sharing its stand with Haver & Boecker, its European sales representative, offers its Flex-Mat 3 high-performance, self-cleaning screen media, which it claims helps screening operations increase screen capacity and material throughput while reducing downtime. Available for tensioned or modular screen decks, Flex-Mat 3 panels (now in its third generation since its introduc

January 6, 2017

Read time: 2 mins

The Montreal, Canada-based company, sharing its stand with Haver & Boecker, its European sales representative, offers its Flex-Mat 3 high-performance, self-cleaning screen media, which it claims helps screening operations increase screen capacity and material throughput while reducing downtime.

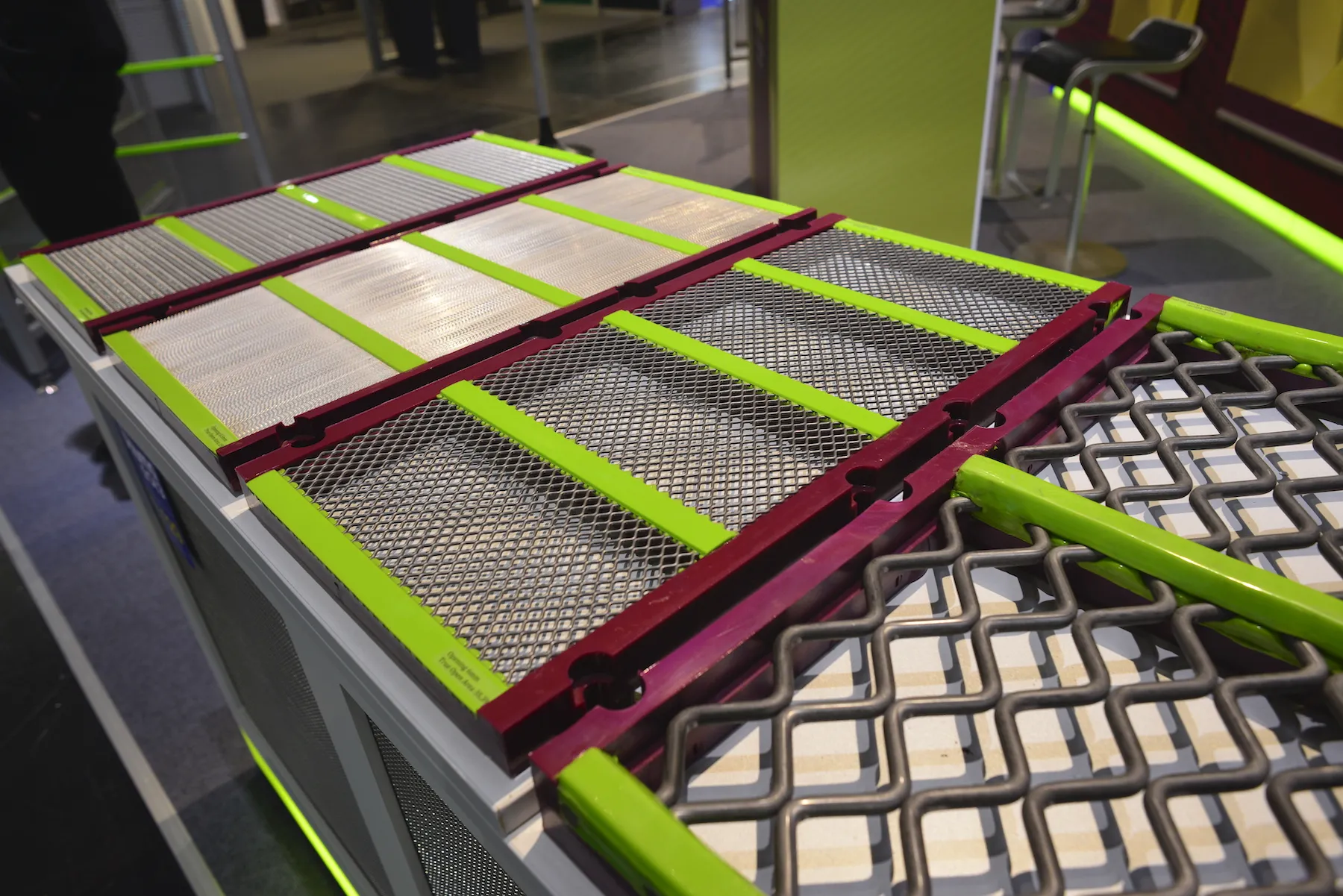

Available for tensioned or modular screen decks, Flex-Mat 3 panels (now in its third generation since its introduction in 1996) are said to provide up to 30% more screen capacity than traditional woven wire and up to 50% more screen capacity than polyurethane and rubber panels in applications including aggregate, mining, sand and gravel. Independently vibrating wires increase the open area and are said to eliminate blinding, pegging and clogging.

For tensioned screen decks, Flex-Mat 3 Tensioned’s lime green polyurethane strips align to the screen box’s crown bars and hold individual wires in place as they run from hook to hook. It is available in a broad range of opening sizes (30 mesh to 102mm).

Major Wire says that on modular screen decks, Flex-Mat 3 Modular 305mm x 305-mm and 305mm x 610mm panels use the same frames and installation types as traditional polyurethane and rubber panels, which they can replace.

Stand: B2.129/236

%$Linker: