All round visibility from the operator’s seat of a construction machine is a topic in focus at the EU Commission. This has been a topic of concern for the construction machinery sector ever since the EU Commission released a warning relating to the standard. This standard has provisions covering visibility requirements for earth-moving machinery. A position paper is intended to help clarify the situation.

November 9, 2015

Read time: 3 mins

All round visibility from the operator’s seat of a construction machine is a topic in focus at the EU Commission. This has been a topic of concern for the construction machinery sector ever since the EU Commission released a warning relating to the standard. This standard has provisions covering visibility requirements for earth-moving machinery. A position paper is intended to help clarify the situation.

The warning issued by the EU Commission is in relation to the requirements set out in European standard EN 474-1 on visibility for earth-moving machinery. It came into effect on 28th January 2015. But there has been a lack of clarity as to when an earth-moving machine meets statutory requirements and what measures are required for safe operation in compliance with regulations.

For manufacturers of earthmoving machinery, the warning means that new earth-moving machinery sold after this date may not comply with statutory requirements concerning visibility, even if it meets the EN 474-1 requirement. This could give rise to considerable problems, especially in case of legal proceedings. Since the presumption no longer applies, the manufacturer may under certain circumstances have to prove that the precautions he has taken within the framework of the risk assessment were sufficient. Similar considerations apply to machinery operators. Where an accident occurs as the result of an inadequate risk assessment, this can have significant consequences. The standard committee is currently working on the revision of EN 474-1. But completion and the concomitant lifting of the warning are not to be expected before late 2016, the respective committee (CEN/TC 151) has stated.

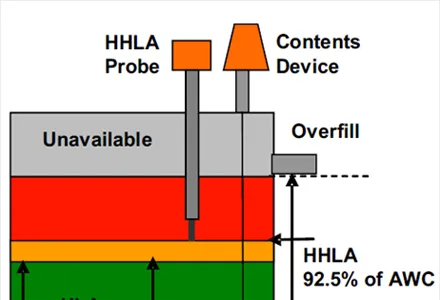

To provide manufacturers and operators with help in the intervening period, the German VDMA1188 Construction Equipment and Building Material Machinery Association has issued a position paper. This provides explanations of the statutory obligations with which the manufacturer must comply with regard to the documentation involved. The responsible EU committee has suggested five points, which the VDMA recommends should be taken into account in the risk assessment. Direct visibility must have priority while near field visibility must be improved by lowering the test specimen from 1.5m to 1m and visibility aids such as camera monitor systems or mirrors must be mounted in the forward direction. Meanwhile visibility aids must not be impaired due to movable machinery parts and mirror-to-mirror systems are not permitted.

If certain machines do not comply with these criteria, the VDMA position paper suggests that measures should be selected which are state of the art and comply with the protection objectives. The camera monitor systems available on the market cannot be considered safety systems and instead should be considered as providing assistance. They cannot replace construction site organisation and communication. Also viewed critically are the visibility maps currently being discussed. These are intended to show the driver which areas the driver cannot see at all or can only see with difficulty. It has not yet been proved that these lead to better safety. The position paper also sets out other arguments against their effectiveness.

Operators and employers are advised to check their risk assessments meticulously for each machine application and to update them where necessary. During the current transitional period there should be an "emphasis on organisational and personal protective measures". This can include increased use of additional human guides and the adjustment of construction site organisation. The VDMA position paper also suggests referring to the rules of the Employers’ Liability Insurance Association for the Construction Industry concerning earth-moving machinery (BGR 500, Clause 2.12) and the document published by the Federal Institute for Occupational Safety and Health entitled "Bekanntmachung zur Betriebssicherheit 2111" (Information on occupational safety 2111).

The warning issued by the EU Commission is in relation to the requirements set out in European standard EN 474-1 on visibility for earth-moving machinery. It came into effect on 28th January 2015. But there has been a lack of clarity as to when an earth-moving machine meets statutory requirements and what measures are required for safe operation in compliance with regulations.

For manufacturers of earthmoving machinery, the warning means that new earth-moving machinery sold after this date may not comply with statutory requirements concerning visibility, even if it meets the EN 474-1 requirement. This could give rise to considerable problems, especially in case of legal proceedings. Since the presumption no longer applies, the manufacturer may under certain circumstances have to prove that the precautions he has taken within the framework of the risk assessment were sufficient. Similar considerations apply to machinery operators. Where an accident occurs as the result of an inadequate risk assessment, this can have significant consequences. The standard committee is currently working on the revision of EN 474-1. But completion and the concomitant lifting of the warning are not to be expected before late 2016, the respective committee (CEN/TC 151) has stated.

To provide manufacturers and operators with help in the intervening period, the German VDMA

If certain machines do not comply with these criteria, the VDMA position paper suggests that measures should be selected which are state of the art and comply with the protection objectives. The camera monitor systems available on the market cannot be considered safety systems and instead should be considered as providing assistance. They cannot replace construction site organisation and communication. Also viewed critically are the visibility maps currently being discussed. These are intended to show the driver which areas the driver cannot see at all or can only see with difficulty. It has not yet been proved that these lead to better safety. The position paper also sets out other arguments against their effectiveness.

Operators and employers are advised to check their risk assessments meticulously for each machine application and to update them where necessary. During the current transitional period there should be an "emphasis on organisational and personal protective measures". This can include increased use of additional human guides and the adjustment of construction site organisation. The VDMA position paper also suggests referring to the rules of the Employers’ Liability Insurance Association for the Construction Industry concerning earth-moving machinery (BGR 500, Clause 2.12) and the document published by the Federal Institute for Occupational Safety and Health entitled "Bekanntmachung zur Betriebssicherheit 2111" (Information on occupational safety 2111).