Topcon and Komatsu are gearing up their long running partnership to a new level, and which will be implemented on a global basis. Although the firms have been co-operating internationally for some years, this partnership has been particularly active in the European market for machine control technology. Under the terms of the deal, customers will be able to order Komatsu machines that are factory-fitted with Topcon technology. Sensors will be fitted in the hydraulic rams of bulldozers, graders and excavator

January 6, 2017

Read time: 2 mins

Sensors will be fitted in the hydraulic rams of bulldozers, graders and excavators for instance, which will allow far greater degrees of accuracy and durability than by using equipment mounted on masts. Achiel Sturm said, “We’ll be able to connect excavators to the dump trucks working together and be able to gather data in the workplace based out of a central hub. The way ahead in the future will be to communicate with all machines from all companies using common architecture.” He added that this would not be limited to machines from Komatsu either and would encompass equipment from other manufacturers with Topcon works closely such as

This deal is of note as it follows on from Topcon’s recent agreement with software specialist Autodesk to improve the interoperability of their respective technologies and products. Under this agreement, Topcon and

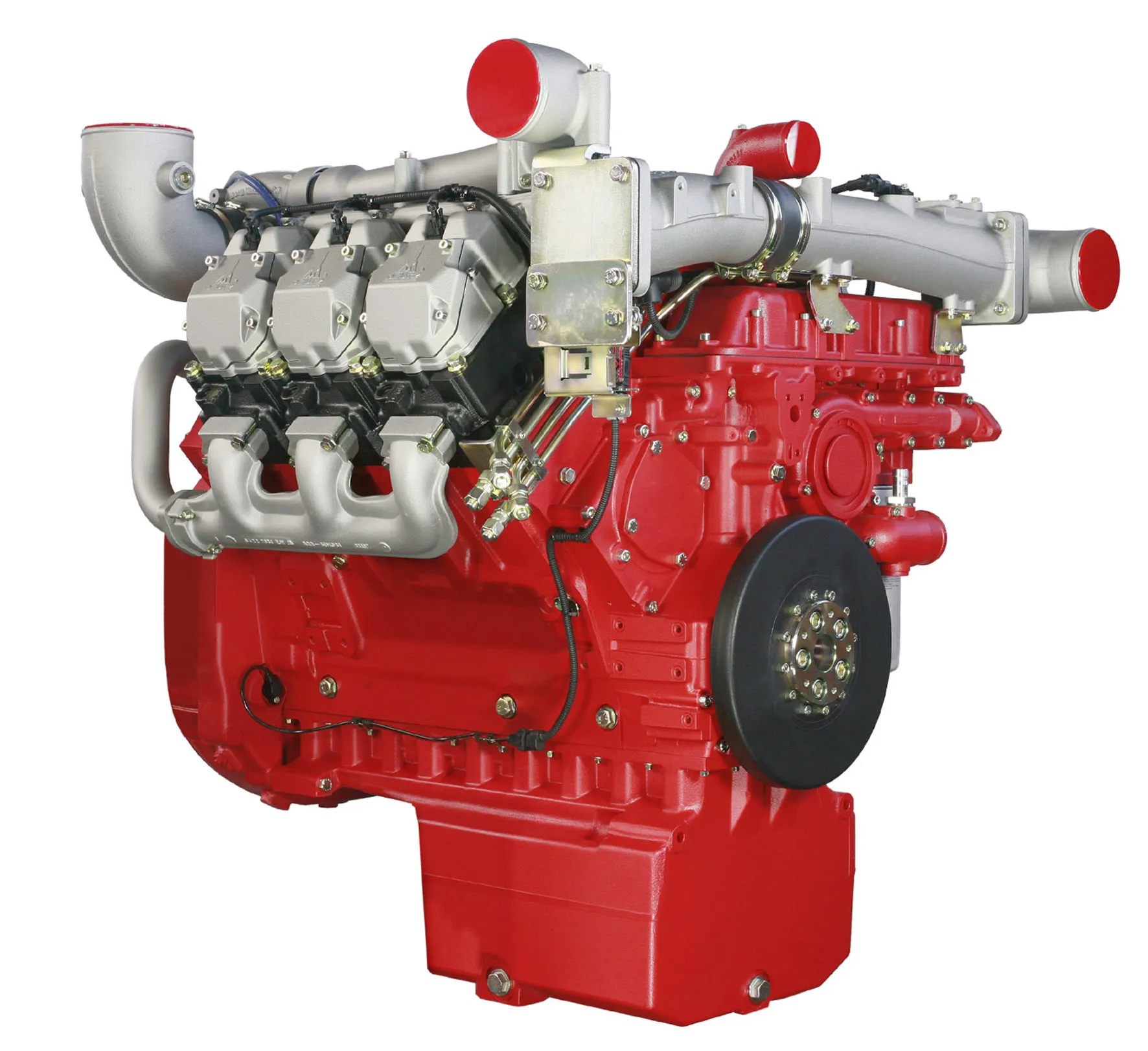

A3.233/332

F11.1111/4

%$Linker:

%$Linker: