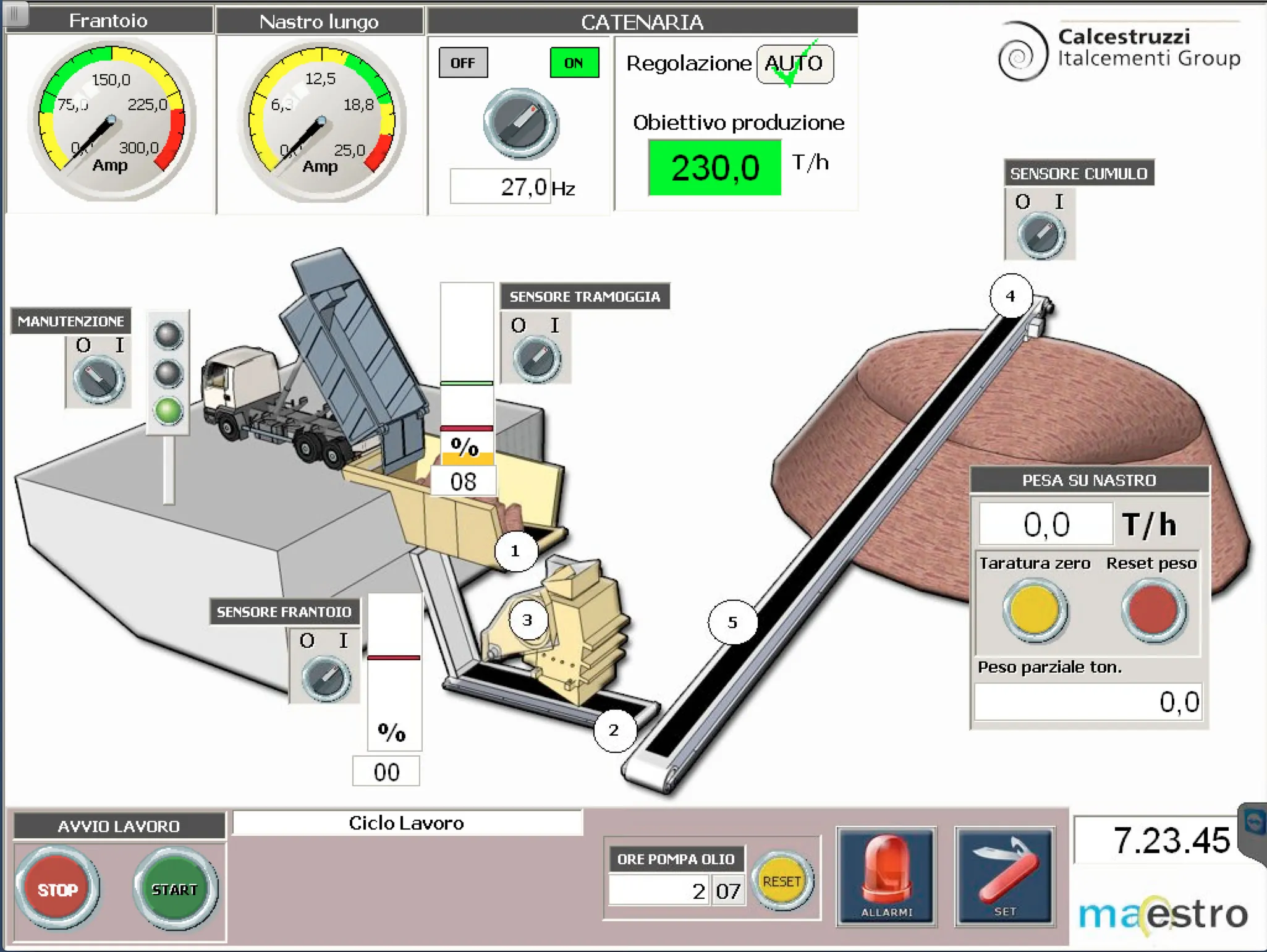

Ma-estro specialises in streamlining quarrying activities through the use of integrated, easy-to-use IT solutions. From standardised control systems to complete customised systems for the automation and full control of the plant, Trentino-based Ma-estro says its flexible software is capable of providing all the significant data required for calculating production costs in real time. The firm’s range of solutions includes Q-Production - for monitoring of production and energy consumption; Q-Control - for pla

April 8, 2013

Read time: 1 min

From standardised control systems to complete customised systems for the automation and full control of the plant, Trentino-based Ma-estro says its flexible software is capable of providing all the significant data required for calculating production costs in real time.

The firm’s range of solutions includes Q-Production - for monitoring of production and energy consumption; Q-Control - for plant automation; Q-Maintenance – for automated maintenance management; and Q-Fuel - for monitoring fuel consumption.

Giorgio Manara, Ma-estro’s owner and founder, comes from a family of quarry operators who continue to manage inert materials production plants in Pilcante di Ala (TN). The family’s work is said to have inspired the creation of Ma-estro’s IT solutions aimed at reducing consumption, eliminating waste and knowing the exact cost per tonne of produced inert material.

Stand: C2.102

%$Linker: